Chapter G - PARTS REPLACEMENT & REPAIR

Planmeca Compact i G-35

MOTORS REPLACEMENT

Technical Manual

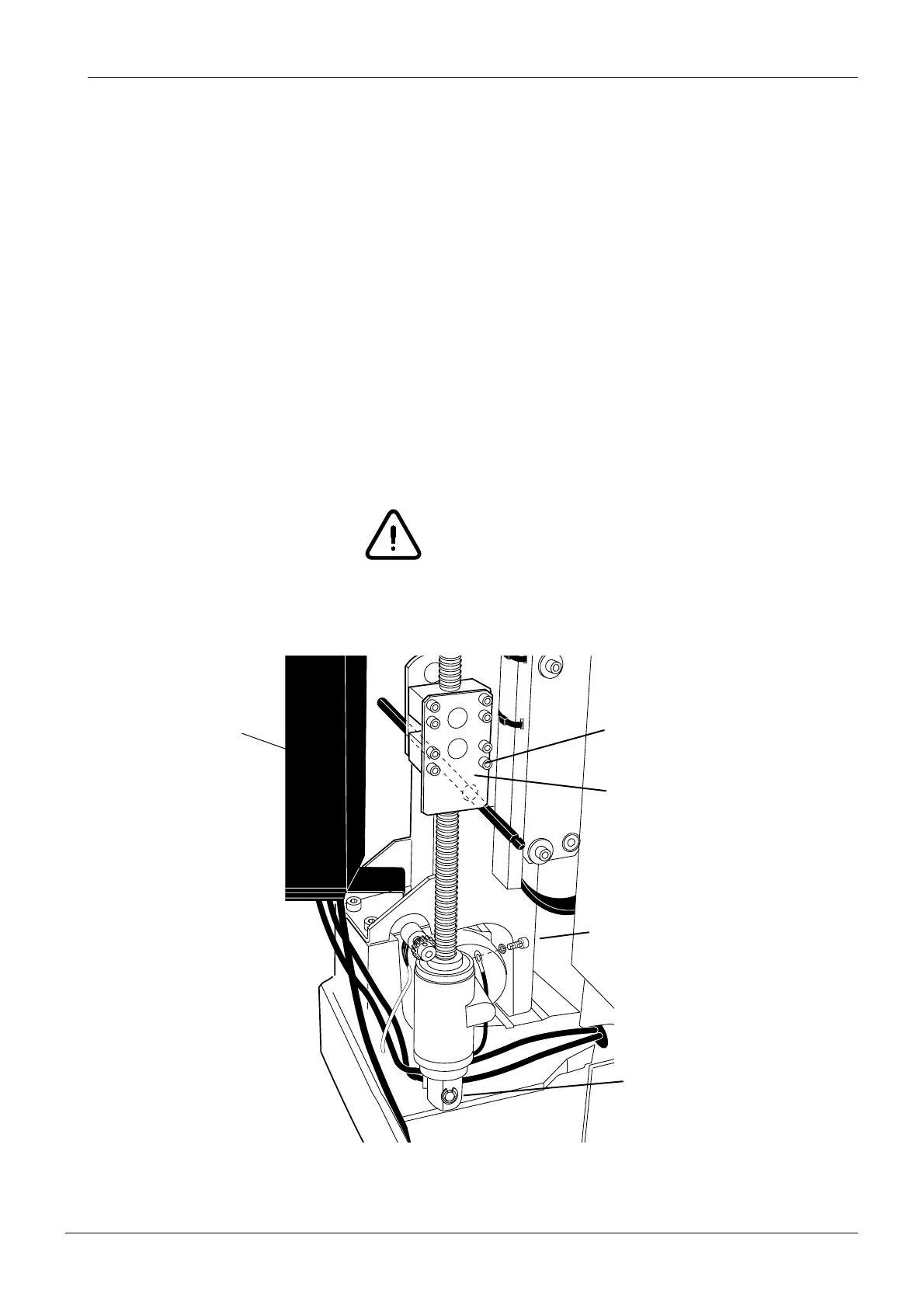

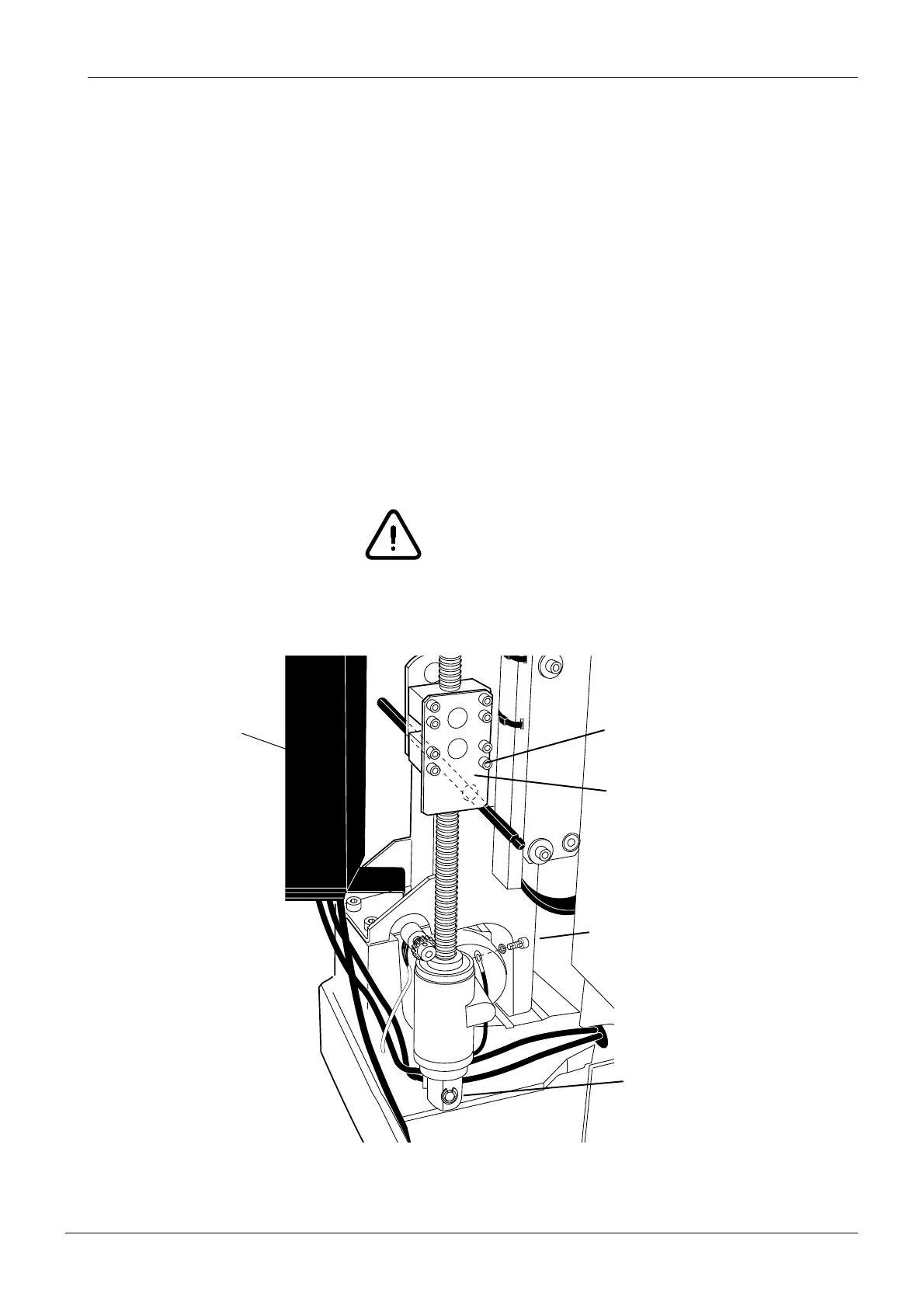

k) Unscrew the eight M6x45 DIN 912 screws that hold the nut attachment plate in position.

l) Remove the nut attachment plate and the lifting frames.

m) Remove the ø10 DIN 6799 locking ring from the lift motor attachment axle.

n) Slide the lift motor from the attachment axle and turn it in a way that the Motor grounding

cable can be detached. Detach the Motor grounding cable from the side of the motor.

o) Lift the Lift motor from the cuspidor.

p) Unscrew the M10x25 ULS screw from the end of the worm screw and remove the worm

screw nut.

q) Detach the lift motor position sensor by unscrewing the two M5x12 DIN 7500 screws.

r) Grease the new motor’s worm screw. Install the new lift motor in reverse order.

NOTE Pay attention when reconnecting the lift motor position sensor, refer to section

5.8 “Replacing position sensors” on page G-26.

NOTE Calibrate the lift motor position sensor as described in section 2.2 “Calibrating

lift motor position sensor” on page F-20.

Unscrew the eight screws

Ensure that the steel bar

is supporting the whole

weight of the chair!

Remove the nut attachment plate

and the lifting frames

Remove the locking ring

Detach the grounding cable

Electronics

control box

lifted aside

Loading...

Loading...