10.35

ELECTRICAL

10

9924096 - 2013 RANGER RZR XP 900 / RZR XP 4 900 Service Manual

© Copyright 2012 Polaris Sales Inc.

STARTING SYSTEM

Troubleshooting

Starter Motor Does Not Run

• Battery discharged

• Loose or faulty battery cables or corroded

connections (see Voltage Drop Tests)

• Related wiring loose, disconnected, or corroded

• Poor ground connections at battery cable, starter

motor or starter solenoid (see Voltage Drop Tests)

• Faulty key switch

• Faulty starter solenoid or starter motor

• Engine problem - seized or binding (can engine be

rotated easily)

Starter Motor Turns Over Slowly

• Battery discharged

• Excessive circuit resistance - poor connections

(see Voltage Drop Test)

• Engine problem - seized or binding (can engine be

rotated easily)

• Faulty or worn brushes in starter motor

Starter Motor Turns - Engine Does Not Rotate

• Faulty starter drive

• Faulty starter drive gears or starter motor gear

• Faulty flywheel gear or loose flywheel

Voltage Drop Test

The Voltage Drop Test is used to test for bad connections.

When performing the test, you are testing the amount of

voltage drop through the connection. A poor or corroded

connection will appear as a high voltage reading. Voltage

shown on the meter when testing connections should not

exceed 0.1 VDC per connection or component.

To perform the test, place the meter on DC volts and place

the meter leads across the connection to be tested. Refer

to the voltage drop tests on the starter system in this

chapter.

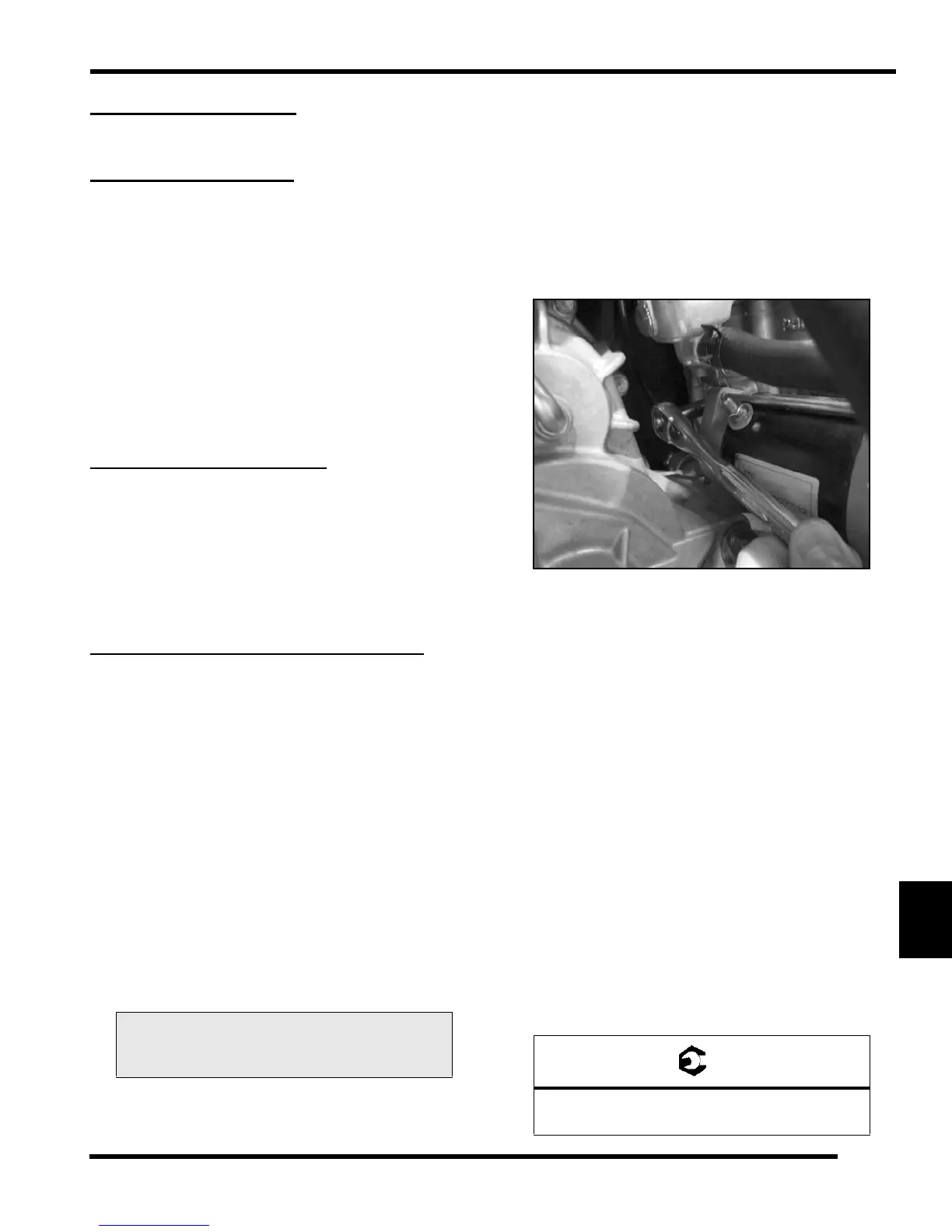

Starter Motor Removal

1. Remove driver side seat and disconnect the battery.

2. Raise and support rear of vehicle.

3. Remove the RH rear wheel.

4. Remove (+) positive wire from starter motor terminal.

5. From the RH side wheel well using an 8mm flex

socket, remove the negative battery cable nut and the

(2) fasteners securing the starter motor to the engine.

NOTE: The (-) negative battery cable is mounted to

the engine using the upper starter mounting bolt /

stud.

6. Remove the starter from the engine.

Starter Motor Installation

1. Inspect and replace starter motor O-ring if needed.

2. Lubricate starter motor O-ring with fresh engine oil.

3. Install the starter motor onto the engine case.

4. Hand tighten the upper starter mounting bolt / stud.

5. Install and torque the lower mounting bolt to

specification.

IMPORTANT: Tighten the lower starter bolt first, as

the bottom hole acts as a pilot hole to properly align

the starter drive (bendix) with the flywheel. This helps

prevent binding and starter damage.

6. Torque upper starter mounting screw to specification.

7. Install (-) negative battery cable to the upper starter

mounting bolt / stud. Torque nut to specification.

Voltage should not exceed

.1 DC volts per connection

Starter Mounting Bolts and Nut:

7 ft-lbs (10 Nm)

Loading...

Loading...