3. Preventive Maintenance

PM Table

There are no PM Parts in this machine.

Service Call Procedures

The procedures listed below should be done by the service technician. For more details about how to do

these procedures, please refer to "Cleaning Procedures".

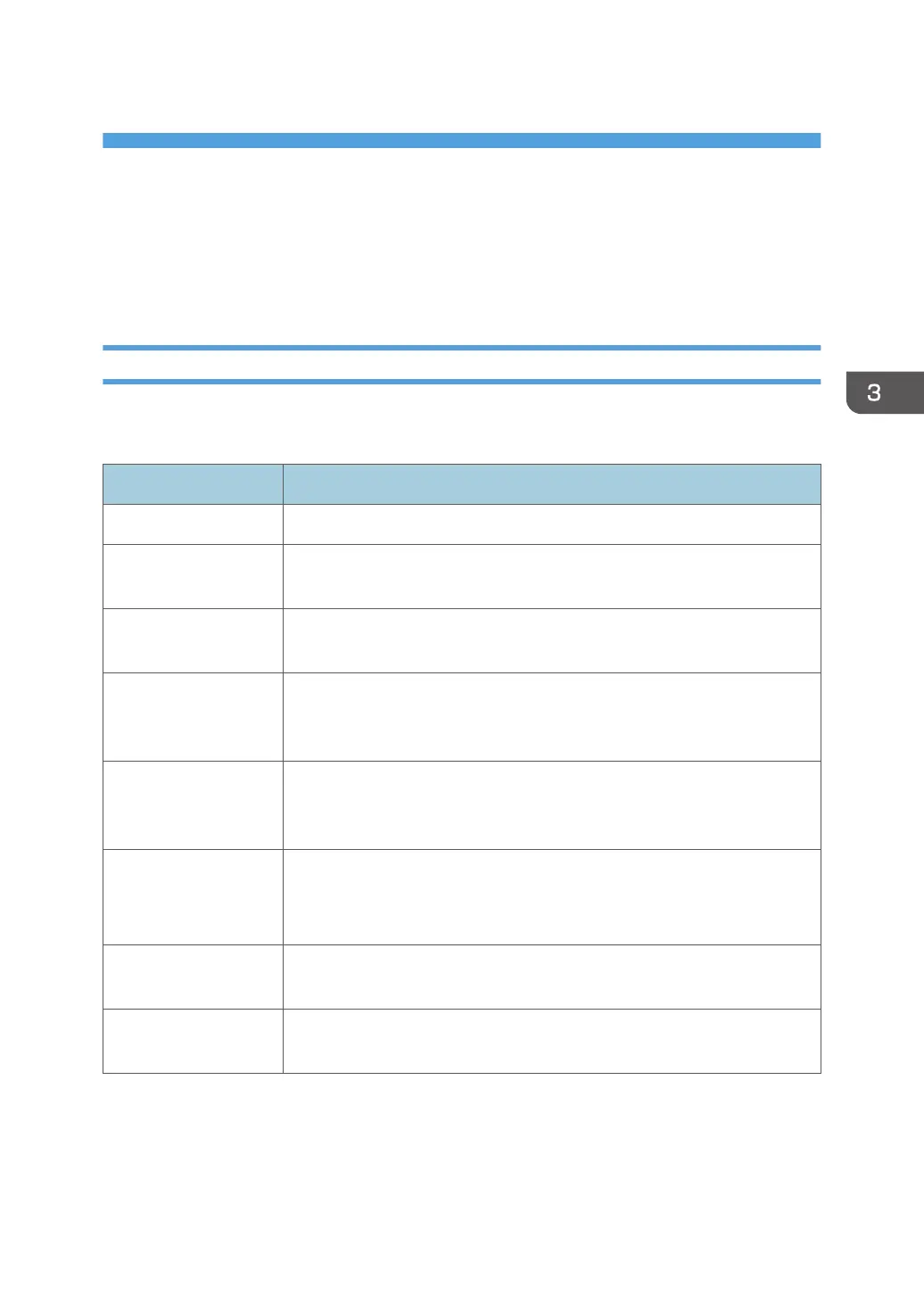

Description At Service Call, or As Required

External Covers Damp cloth.

Connecting Rollers,

Paper Feed Roller

Damp cloth. Rotate the roller freely as you clean it.

Friction Pad Damp cloth. This is the cork friction pad on the front edge of the standard

paper cassette.

Maintenance Unit Damp cloth. Always use a tightly wrapped damp cloth to remove the ink

that has hardened around the suction cap and wiper blade when you

replace the ink collector unit.

Printer Operation, Print

Quality

Print a Nozzle Check Pattern and check the results. Clean the print heads if

necessary. For more, see "Print Head Cleaning and Adjustment" in section

"4. Replacement and Adjustment".

Transport Belt Slightly damp cloth. Then dry cloth.

Important: To protect the surface of the transport belt, never use alcohol or

any other type of organic solvent.

Horizontal Encoder

Strip

Clean linen cloth, dampened with alcohol. Do not use cotton, tissue paper,

any material that could shred and leave fibers.

Vertical Encoder Wheel Clean linen cloth, dampened with alcohol. Do not use cotton, tissue paper,

any material that could shred and leave fibers.

43

Loading...

Loading...