DCR-PC101/PC101E

5-50

3-3. SERVO AND RF SYSTEM ADJUSTMENTS

Before perform the servo and RF system adjustments, check that

the specified values of “66MHz/54MHz Origin Oscillation Ad-

justment” of “1-3. CAMERA SYSTEM ADJUSTMENTS” is sat-

isfied.

Check that the data of page: 0, address: 10 is “00”.

If not, select page: 0, address: 10, and set the data “00”.

Adjusting Procedure:

1. CAP FG duty adjustment

2. PLL f

0

& LPF f

0

Pre-adjustment

3. Switching position adjustment

4. AGC center level and APC & AEQ adjustment

5. PLL f

0

& LPF f

0

final adjustment

1. CAP FG Duty Adjustment (VC-284 board)

RadarW

RadarW

RadarW

Set the CAP FG signal duty cycle to 50% to establish an appropri-

ate capstan servo. If deviated, the uneven rotation of capstan and

noise can occur in the LP mode.

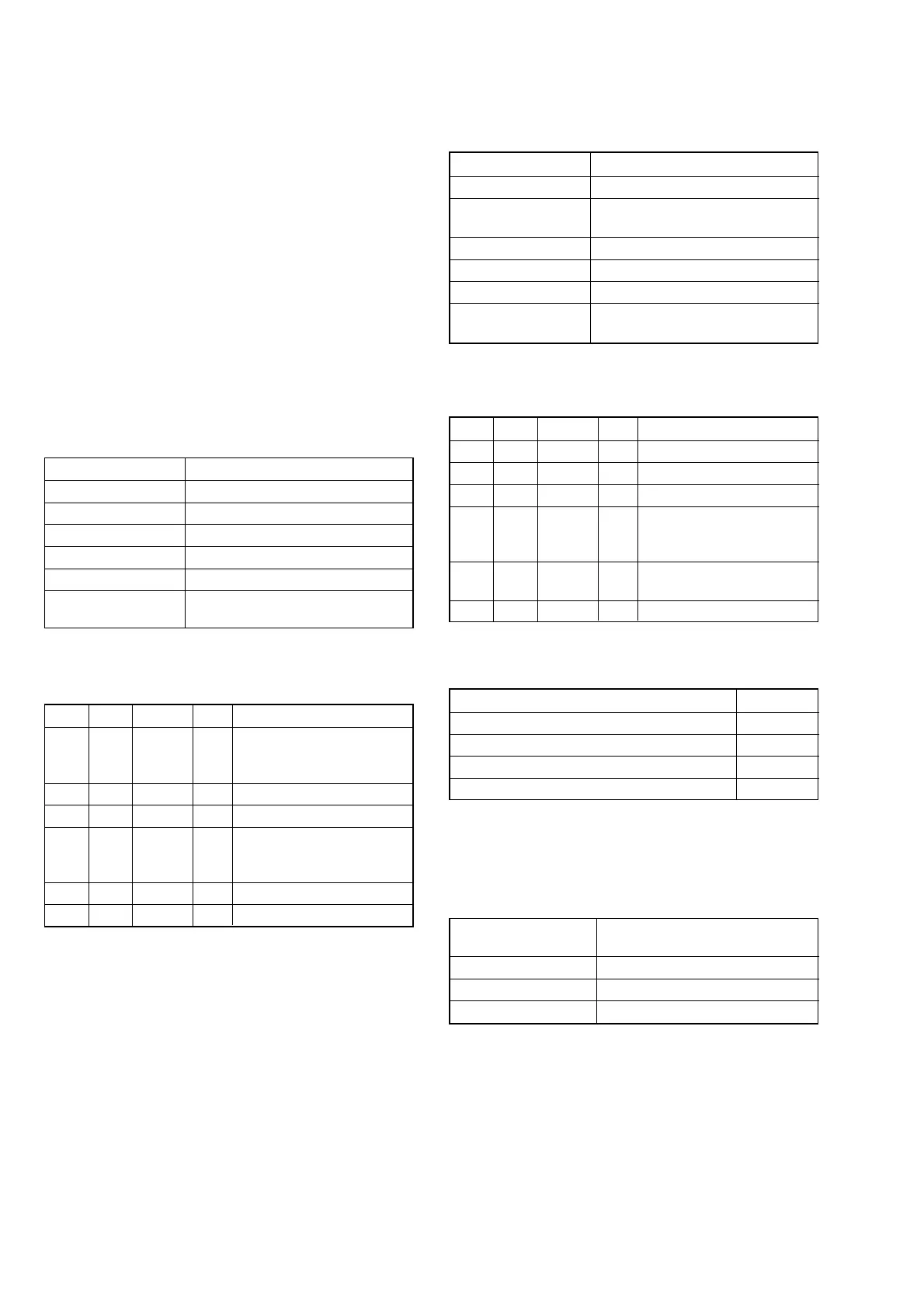

Mode VTR stop

Signal No signal

Measurement Point Displayed data of page: 3, address: 03

Measuring Instrument Adjusting remote commander

Adjustment Page C

Adjustment Address 16

Specified value The data of page: 3, address: 03 is

“00”

Note 1: Check that the data of page: 0, address: 10 is “00”.

Adjusting method:

Order Page Address Data Procedure

1

Close the cassette compart-

ment without inserting

cassette.

2 0 01 01

3 3 01 1B Press PAUSE button.

43 02

Check the data changes in

the following order

“1B” t “2B” t “00”

5 3 03 Check the data is “00”. (Note 2)

6 0 01 00

Note 2: If the data is “01”, adjustment has errors or the mecha-

nism deck is defective.

2. PLL f

0

& LPF f

0

Pre-Adjustment (VC-284 board)

RadarW

RadarW

RadarW

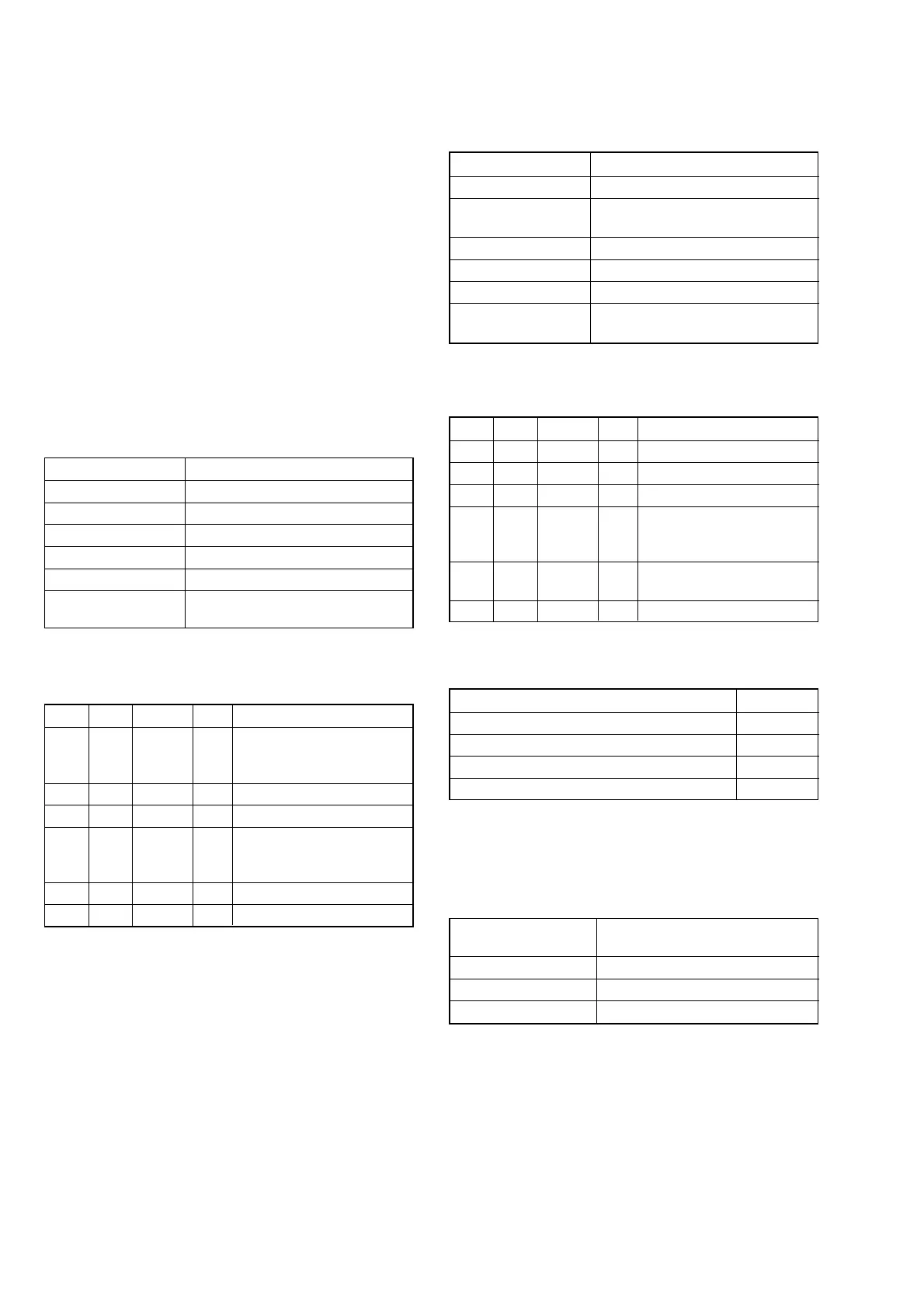

Mode VTR stop

Signal No signal

Measurement Point Displayed data of page: 3, address:

02 and 03

Measuring Instrument Adjusting remote commander

Adjustment Page C

Adjustment Address 1F, 20, 22, 29

Specified value The data of page: 3, address: 02 is “00”

The data of page: 3, address: 03 is “00”

Note 1: Check that the data of page: 0, address: 10 is “00”.

Adjusting method:

Order Page Address Data Procedure

1 0 01 01

2 C 21 DC Press PAUSE button.

3 3 01 30 Press PAUSE button.

43 02

Check the data changes to

“00” within 5 seconds.

(Note 2)

53 03

Check the data is “00”.

(Note 2, 3)

6 0 01 00

Note 2: If check is NG, select page: C, address: 21, set the fol-

lowing data, and press the PAUSE button, and repeat steps

3 to 5.

Setting data

When the data of page: C, address: 21 is “DC” E0

When the data of page: C, address: 21 is “E0” D8

When the data of page: C, address: 21 is “D8” E4

When the data of page: C, address: 21 is “E4” D4

The adjustment is defective, if the above procedure results in NG.

Note 3: If bit value of bit2, bit3, bit4, bit5 or bit6 is “1”, adjust-

ment has errors. For the error contents, see the follow-

ing table. (For the bit values, refer to “5-4. SERVICE

MODE”, “4-3. 3. Bit value discrimination”.)

Bit value of page: 3,

address: 03 data

Error contents

bit2 = 1 or bit 3 =1 PLL f

0

fine adjustment is defective

bit4 = 1 or bit 5 =1 PLL f

0

adjustment is defective

bit6 = 1 LPF f

0

adjustment is defective

Loading...

Loading...