DCR-PC101/PC101E

5-32

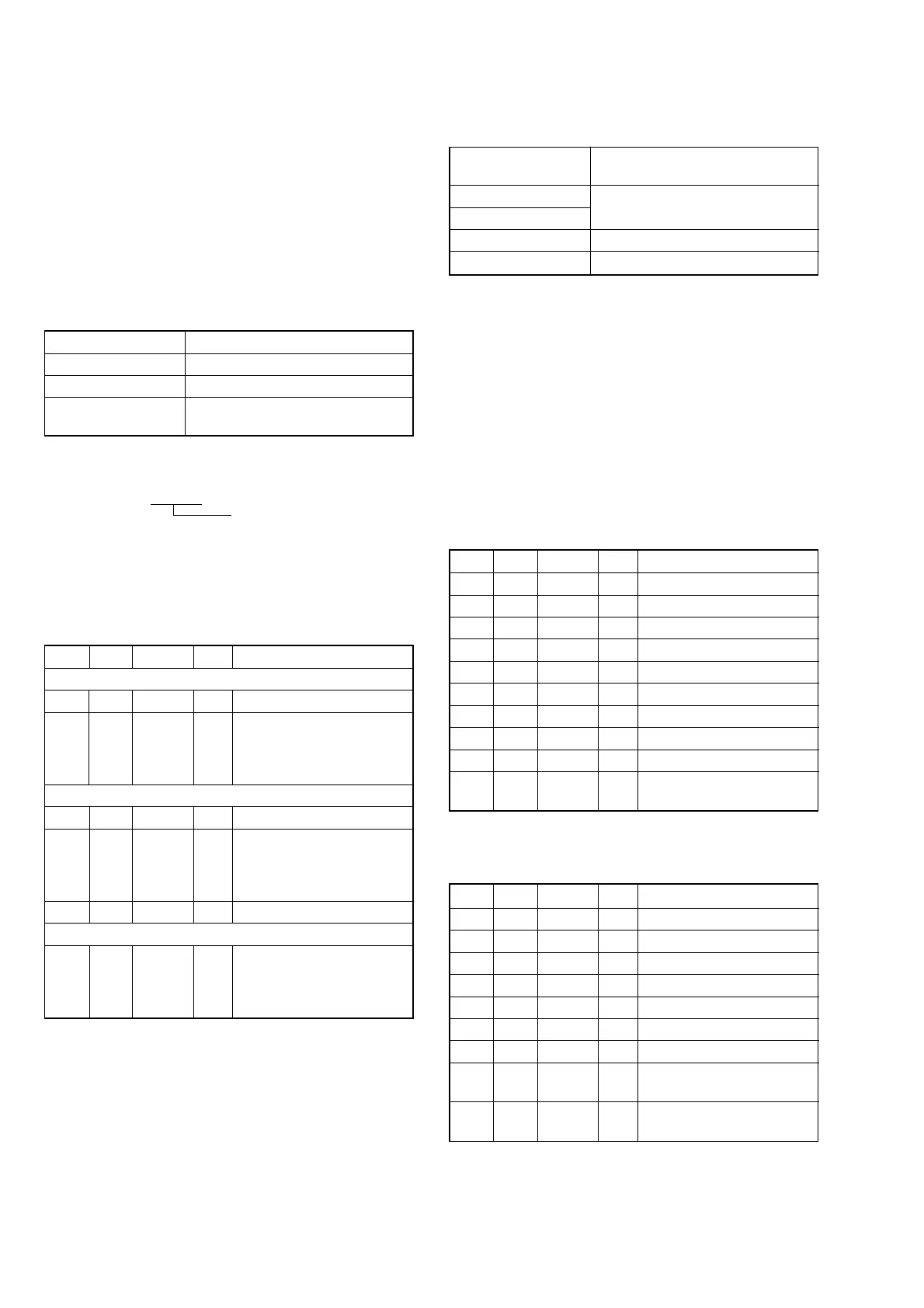

16. CCD Black Defect Adjustment

RadarW

RadarW

RadarW

Detect the black defect position of the CCD imager.

Subject Clear chart (All white)

(40 cm from the front of the lens)

Measurement Point Adjusting remote commander

Measuring Instrument

Adjustment Page 1E

Adjustment Address 20 to 2F

Note 1: If reading/writing data on pages 1E, set data: 01 to page:

0, address: 10, and then select pages E. By this data set-

ting, the pages 1E can be selected.

After the data reading/writing finished, return the data

on page: 0, address: 10 to “00”.

Note 2: Perform “Flange Back Adjustment” before this adjust-

ment.

Note 3: Check that the data of page: 6, address: 02 is “00”.

If not, turn the power of unit OFF/ON.

Switch setting

1) POWER .................................................................CAMERA

2) NIGHT SHOT.................................................................OFF

Adjusting method:

Order Page Address Data Procedure

1 0 01 01

26 2C01

36 9C01

4 6 90 50

5 6 91 01

6 6 92 00

7 6 93 01

8 6 01 79 Press PAUSE button.

9 6 01 8D Press PAUSE button. (Note 4)

10 6 02

Check the data changes to

“01”.

Note 4: The adjustment data will be automatically input to page:

1E, address: 20 to 2F.

Processing after Completing Adjustment:

Order Page Address Data Procedure

1 6 01 00 Press PAUSE button.

26 2C00

36 9C00

4 6 90 00

5 6 91 00

6 6 93 00

7 0 01 00

8

Turn OFF the main power

supply.

9

Perform “CCD Defect

Check”.

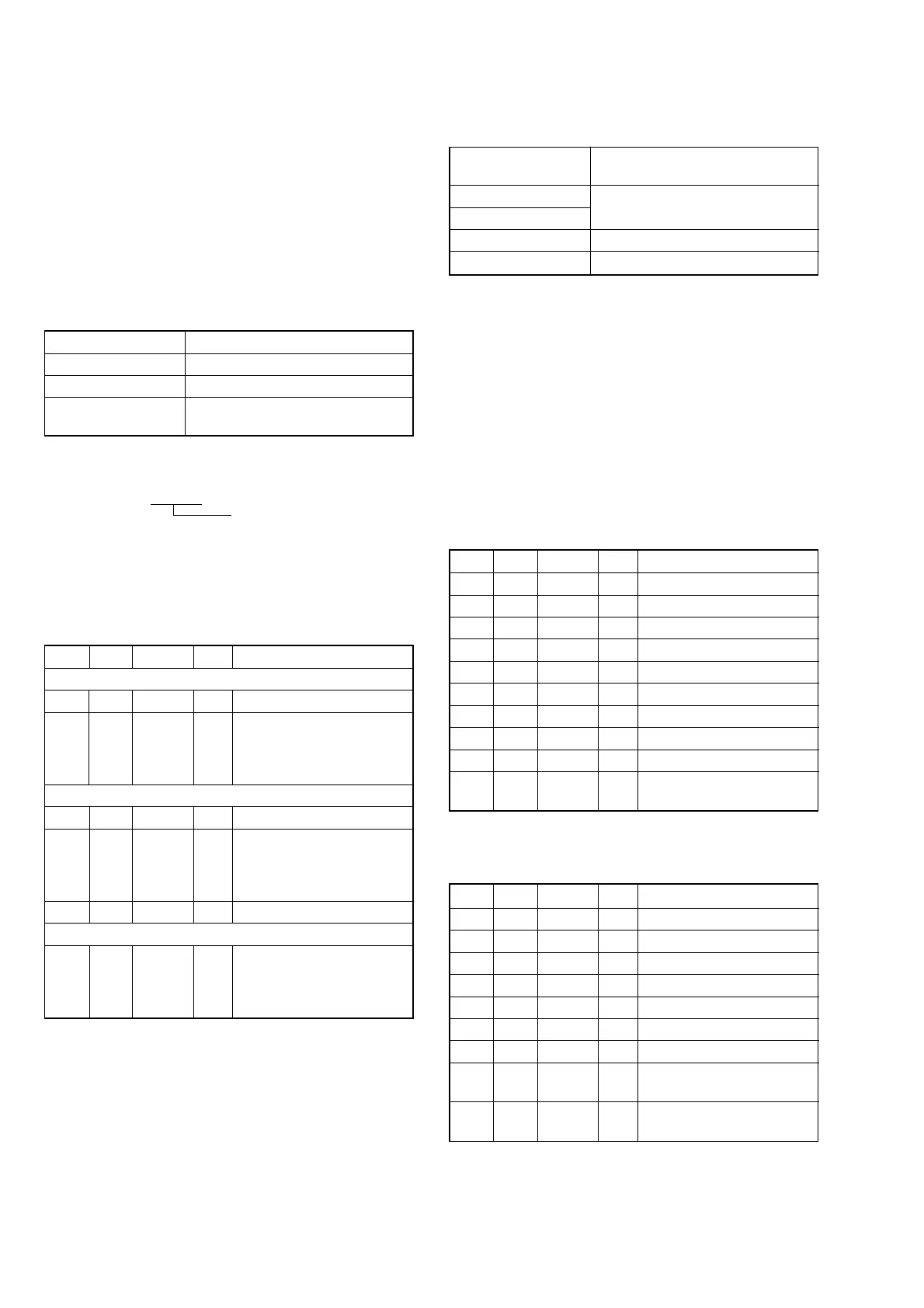

15. Steady shot Check

RadarWRadarWRadarW

Precautions on the Parts Replacement

There are two types of repair parts.

Type A ENC03JA

Type B ENC03JB

Replace the broken sensor with a same type sensor. If replace with

other type parts, the image will vibrate up and down or left and

right during hand-shake correction operations.

Precautions on Angular Velocity Sensor

The sensor incorporates a precision oscillator. Handle it with care

as if it dropped, the balance of the oscillator will be disrupted and

operations will not be performed properly.

Subject Not required

Measurement Point Displayed data of page: 1 (Note 1)

Measuring Instrument Adjusting remote commander

Specified value PITCH data: 2B00 to 4B00

YAW data: 2B00 to 4B00

Note 1: The right four digits of the page: 1 displayed data of the

adjusting remote commander.

1 :

XX : XX

Displayed data

Note 2: Check that the data of page: 0, address: 10 is “00”.

Switch setting

1) ZOOM ..................................................................... TELE end

2) STEADY SHOT (Menu setting) ....................................... ON

Checking method:

Order Page Address Data Procedure

PITCH sensor output check (SE201 of CF-089 board)

1 0 03 11

21

With the set in still state,

check that the displayed data

(Note 1) satisfies the PITCH

data specified value.

YAW sensor output check (SE202 of CF-089 board)

3 0 03 12

41

With the set in still state,

check that the displayed data

(Note 1) satisfies the YAW

data specified value.

5 0 03 00

Steady shot operation check

6

Shake the set vertically and

horizontally to check that the

steady shot function operates

normally.

Loading...

Loading...