Maintenance 141

2006792 Rev B – 200228

Maintenance

The JetStream requires regular maintenance in order to function properly. This section

describes basic maintenance procedures that can be performed by an operator.

WARNING: When working with inks and fluids, always wear gloves, safety

glasses, and protective clothing. Avoid skin contact with inks and fluids. Never look

directly into the Printhead Nozzle. Ensure proper ventilation to minimize fumes.

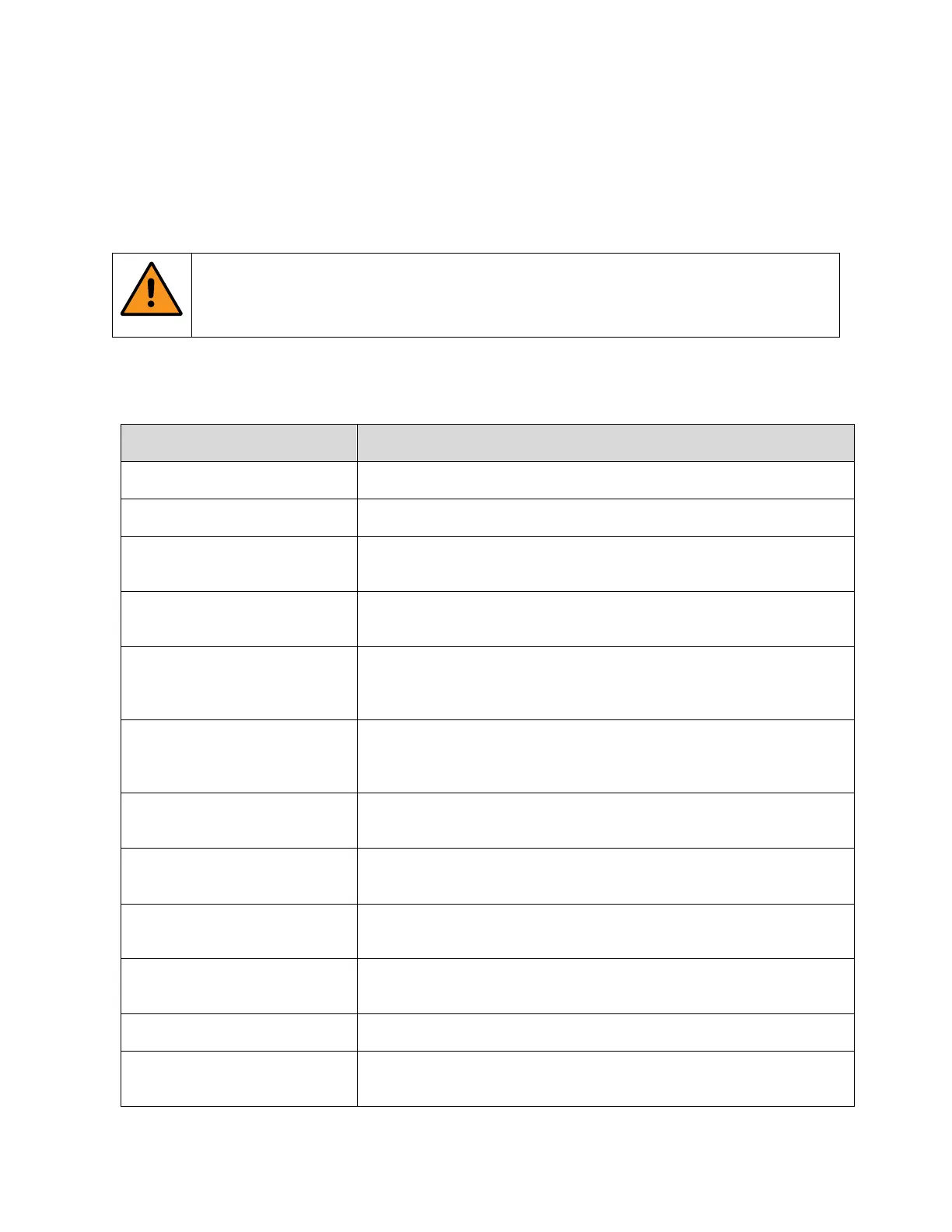

JetStream Maintenance Schedule

Start Jetting With Cleaning

Once daily – beginning of day (see “Daily Maintenance” on page 142)

Stop Jetting With Cleaning

Once daily – end of day (see “Daily Maintenance” on page 142)

Check inside Printhead for ink

build-up

Once daily (see “Cleaning the Printhead” on page 142)

Every 3 days at the beginning or end of day, and as needed (see

“Cleaning the Printhead” on page 142)

Install new Ink Container

When current Ink Container is empty – “Ink Shortage” is displayed on

screen (see “Installing or Changing the Ink and Makeup Fluid” on

page 55)

Install new Makeup Container

When current Makeup Container is empty – “Solvent Shortage” is

displayed on screen (see “Installing or Changing the Ink and Makeup

Fluid” on page 55)

Have distributor replace the

Main Filter Assembly

Every 6000 hours of run time (see “Replacing the Main Filter

Assembly” on page 159)

Have distributor replace the Ink

Feeding Filter (PN: 2006593)

Same time as Main Filter Assembly replacement

Have distributor replace the Ink

Return Filter (PN: 2006709)

Same time as Main Filter Assembly replacement

Have distributor replace the

Cleaning Filter (PN: 2006593)

Same time as Main Filter Assembly replacement

As needed (see “Replacing or Cleaning the Air Filters” on page 164)

Upgrade JetStream system

software

As available: Squid Ink notifies customers of software upgrades via

email (see “Upgrading the System Software” on page 166)

Loading...

Loading...