Chapter 10

197

UM10350_PCNC770_Manual_0916A

Troubleshooting

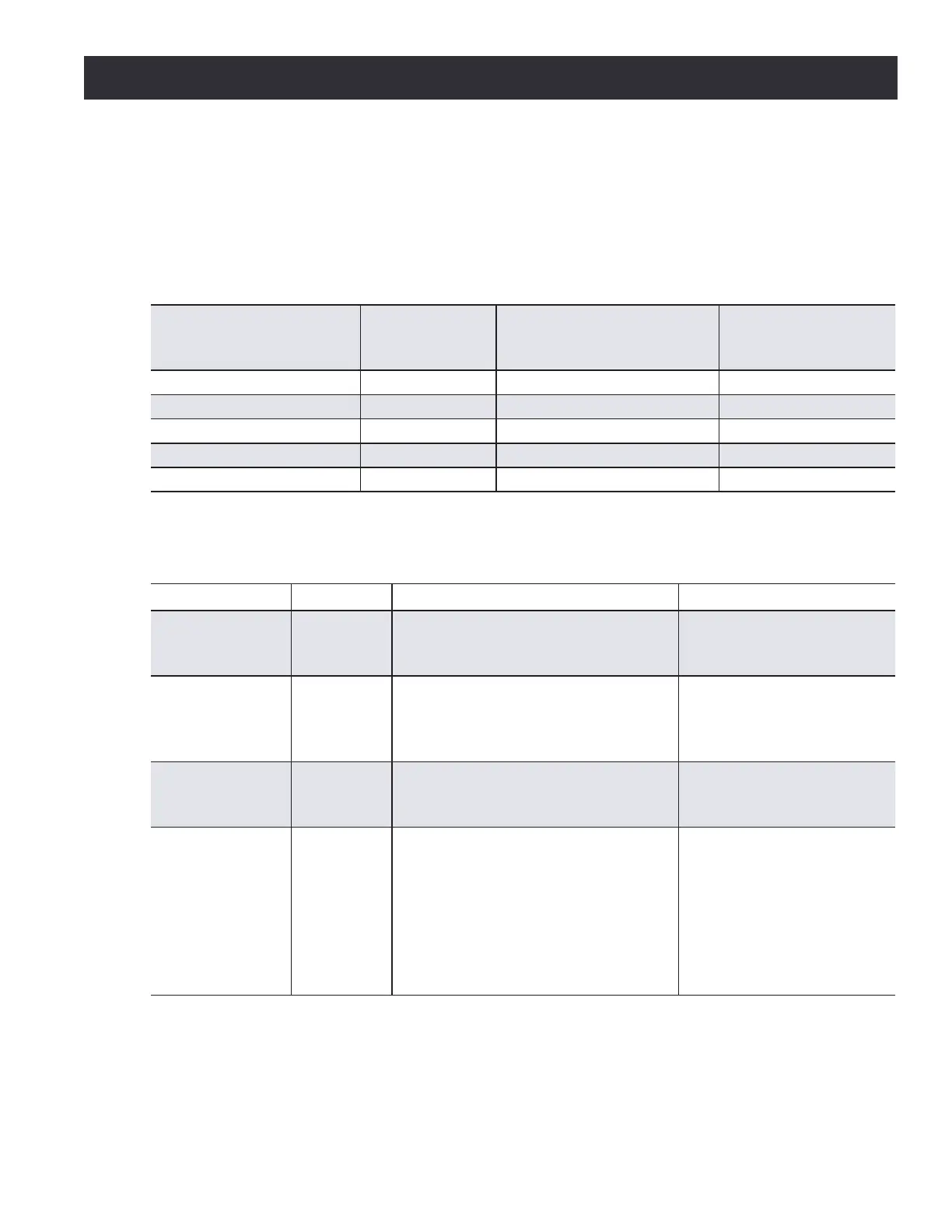

Axis Drive Subsystem Checklist

Table 4.4

DC bus power distribution

The DC bus board contains four fuses which are used to individually fuse power to the axis driver modules.

A fth fuse is provided on the supply boards for the Z-axis brake. Fuses are noted on the circuit board.

Note that the control power circuit must be on (Machine LED is on).

Fuse Number on DC

Bus Board

Function

Wire Numbers to

Monitor with Common

Lead (0V) listed rst

Voltage when DC

Bus is OK and When

Fuse is Good

F1 X X-axis 163 164 55-75 VDC

F2 Y Y-axis 165 166 55-75 VDC

F3 Z Z-axis 167 168 55-75 VDC

F4 A A-axis 169 170 55-75 VDC

F5 Brake Brake for Z-axis 326 327 55-75 VDC

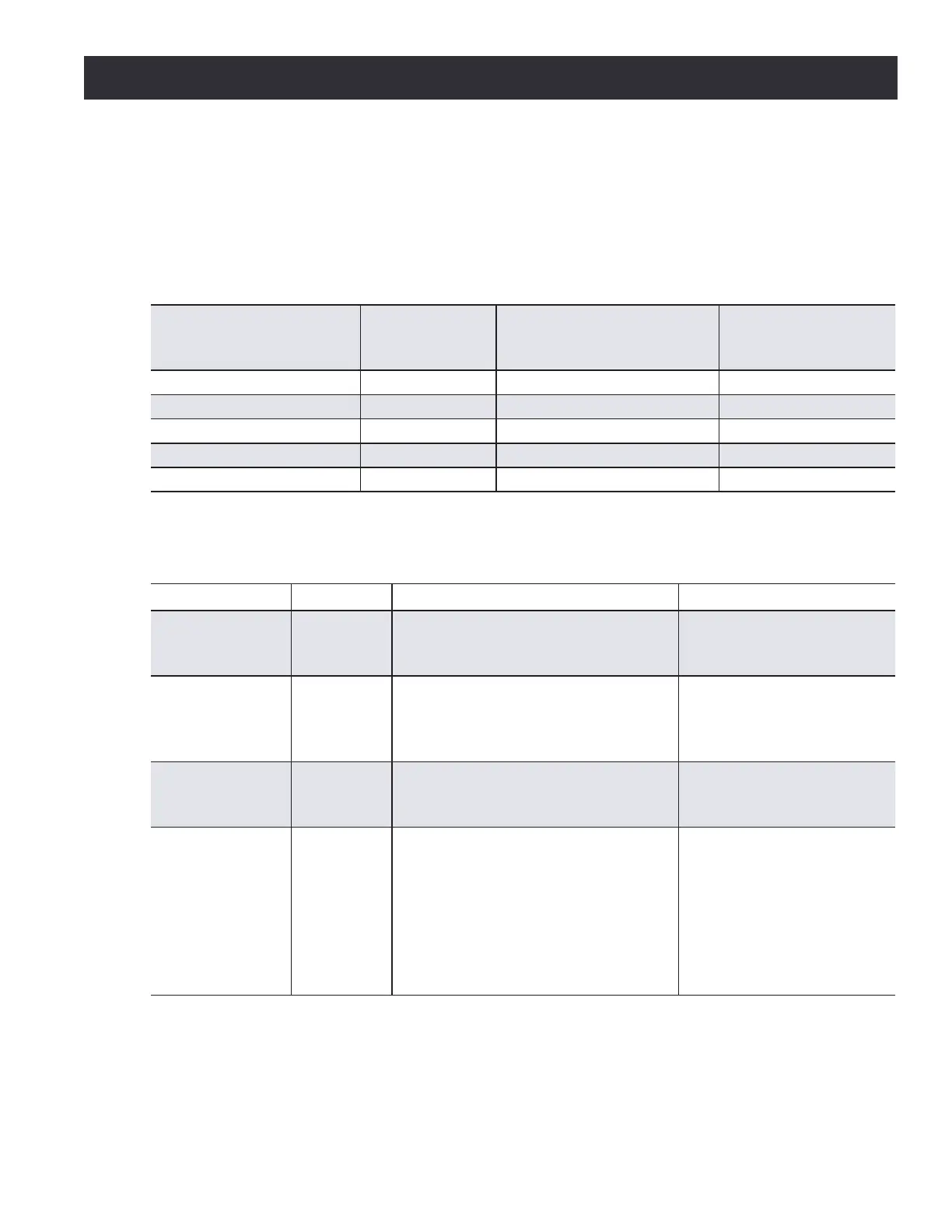

Axes Drive Subsystem Checklist

Table 4.5

Axis movement is extremely noisy or bumps

Possible Cause Probability Action to Identify Cause of Problem Discussion

Loose wire

connection or

failed connector

High/Low

Power off and tighten all screw

connections

Inspect green power

connector for signs

of overheating.

Defective axis

driver module

Medium See Table 4.2

There have been cases of

a noisy axis relating to a

defective driver. This may be

temperature dependant.

Failing controller,

or controller not

suited for M3

Low Contact Tormach Technical Support

A aky controller will not

produce smooth step signals

for good axis motion.

Loose sheet metal High Feel for vibrating sheet metal

Often loose sheet metal is

mistakenly diagnosed as a noisy

axis motor. On some systems,

certain axis motor speeds can

cause excessive vibration in

the sheet metal stands. Identify

problem areas and treat with

butyl tape or silicone sealer..

(connued on next page...)

Loading...

Loading...