Chapter 10

198

UM10350_PCNC770_Manual_0916A

Troubleshooting

Axes Drive Subsystem Checklist

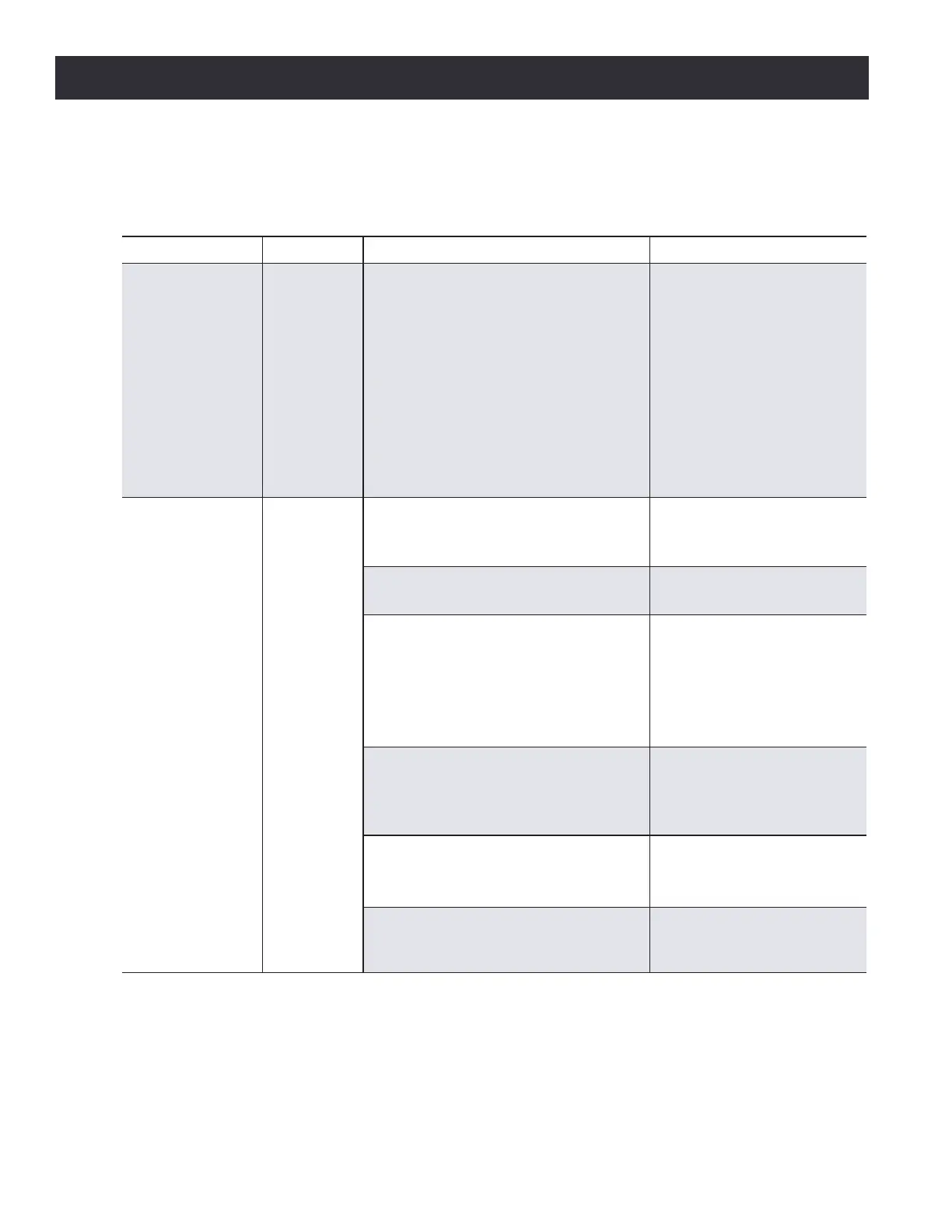

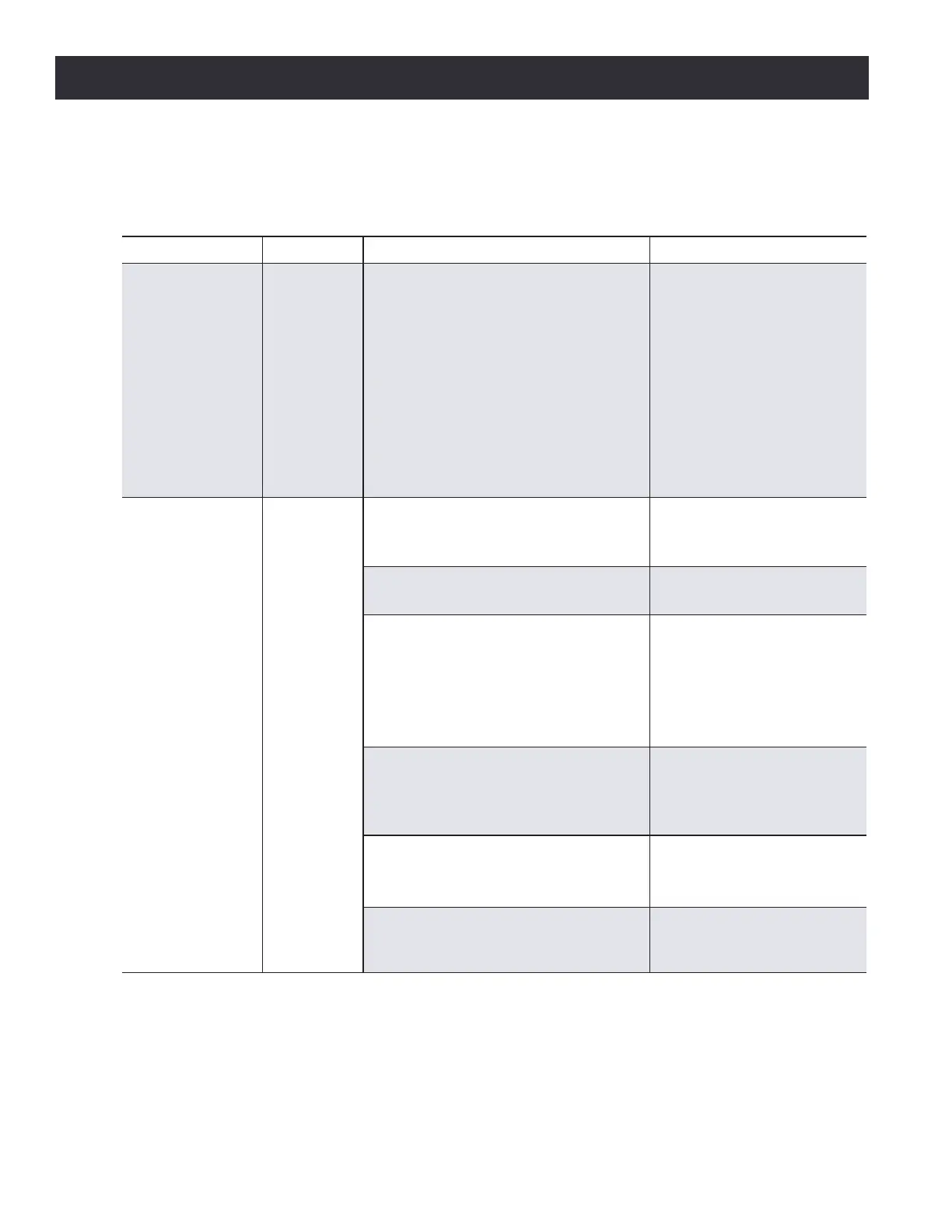

Table 4.5 (...continued)

Axis Movement is Extremely Noisy or “Bumps”

Possible Cause Probability

Action to Identify Cause of Problem

Discussion

Squeaky Z-axis

brake (Z-axis

only)

Low Noise coming from the brake canister.

Removing the brake wires are

short and somewhat fragile –

lift the brake canister off the

motor with caution. Placing a

dab of grease on the motor

spindle shaft and on the

shafts mating surface on the

under side of the brake will

remove excess noise without

compromising the function of

the brakes.

Defective

capacitor for DC

bus board

Low

Power off control power, and unplug the

lower wire connectors on all the axis

drives (X, Y, Z and A).

—

With the electrical cabinet open, power

on control power.

Observe the green LED on

the DC bus board illuminate.

While observing the green LED on the

DC bus board, press the red E-stop.

If the LED extinguishes in two

seconds or less, the capacitor

is defective and must be

replaced. If the LED takes ve

seconds or more to extinguish,

the capacitor is good.

If the results are not conclusive, power

off control power and unplug the power

connectors from the axis drives, if not

already unplugged.

—

Power on control power and measure

DC voltage on wires 300 (common)

and 301 on DC bus board.

A DC voltage of a nominal

65 VDC (55-75) indicates the

capacitor is OK.

Power off control power and plug

the power connectors back on the

axis drives.

A DC voltage of a nominal

40 VDC (35-45) indicates the

capacitor is defective.

Loading...

Loading...