OPTIONS & ALLIED TOOLING − DECO 7/10 − DECO 7a/10a − DECO 7e/10e

300236 en − 02/07 Chap. 7.2 /3

7.2 PRESETTING

GEOMETRY ON THE PRE−SETTER

Operations Notes

Steps to take

Create a mark on the cutter so you

always take the geometry on the

same tooth.

Mount the cutter−holder dolly

Install the equipment on base 10a

and check the roundness. (max 2μ)

Δ Attention! The dollies need to

be clean and free from burrs.

Change the dolly if the tolerance

is not in conformity.

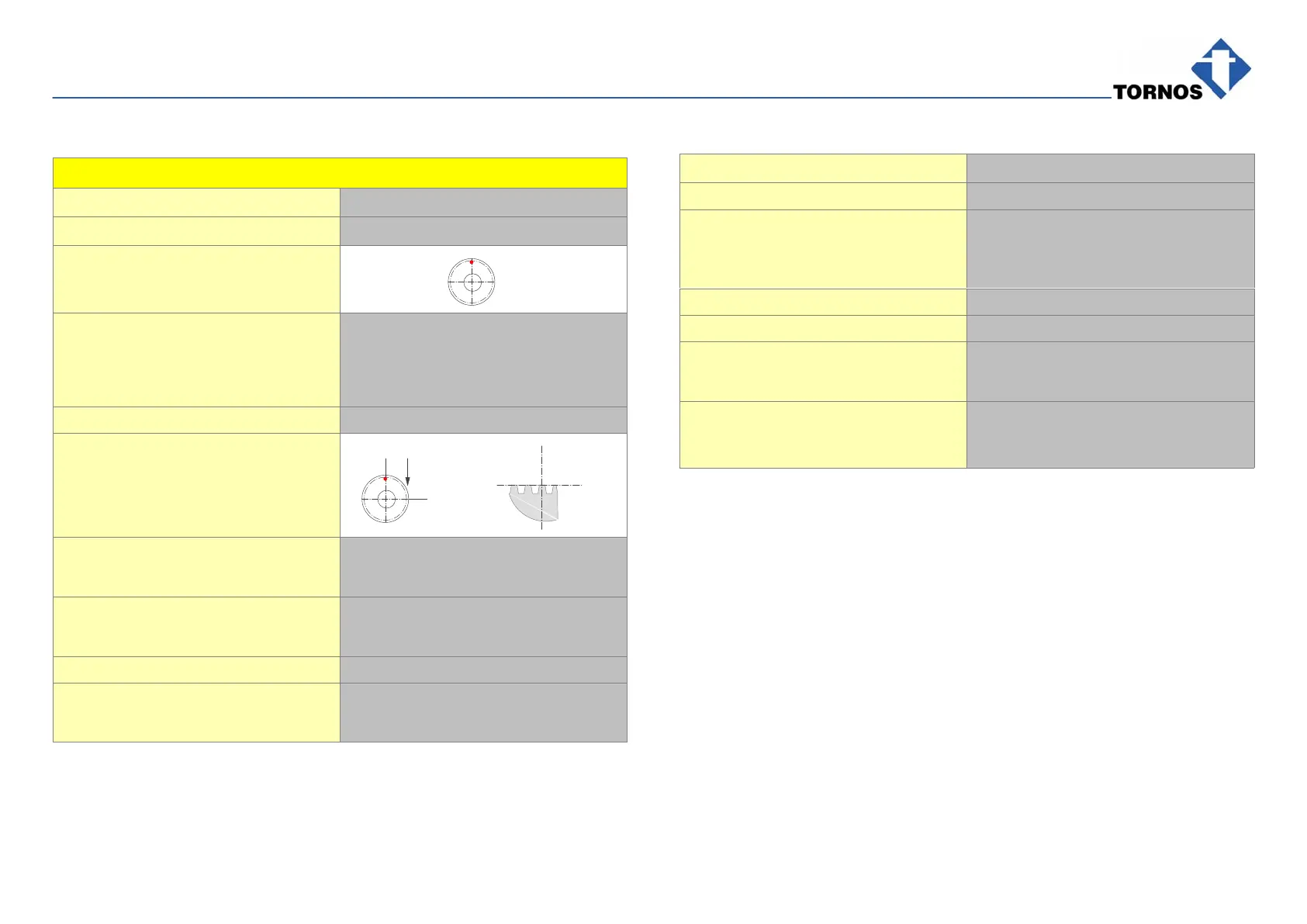

Geometry in X Following the example (pitch = t)

Position in the middle of the first

complete tooth.

Value read: 1.08mm

Y

Z

1/4 t

1/4 t

X

Work: cutter under the part: subtract 1/4 pitch

1,08 − 0,09 = 0,99

Work: cutter on the part: add 1/4 pitch

1,08 + 0,09 = 1,17

Geometry in Z

Value read: −12.98mm

Subtract cutter radius (negative):

−12,98 + −6 = −18,98

Operations Notes

Geometry in Y

Fixing in pos: T22, T23 and T24

Offset of 28.5mm between the pin

and equipment cutter axis

Work:

cutter under and on the part

Work: cutter on the part: −28,5 + −6 = −34,5

Work: cutter under the part: −28,5 − −6 = −22,5

Fixing in pos: T25

Programming and work in T24

Δ Attention! Work: only under the

part.

Offset + cutter radius + fixing pin

centre−to−centre distance on

chaser

−28,5 + −6 + 30 = −4,5

Loading...

Loading...