OPTIONS & ALLIED TOOLING − DECO 7/10 − DECO 7a/10a − DECO 7e/10e

300236 en − 02/07 Chap. 11.2 /2

1002

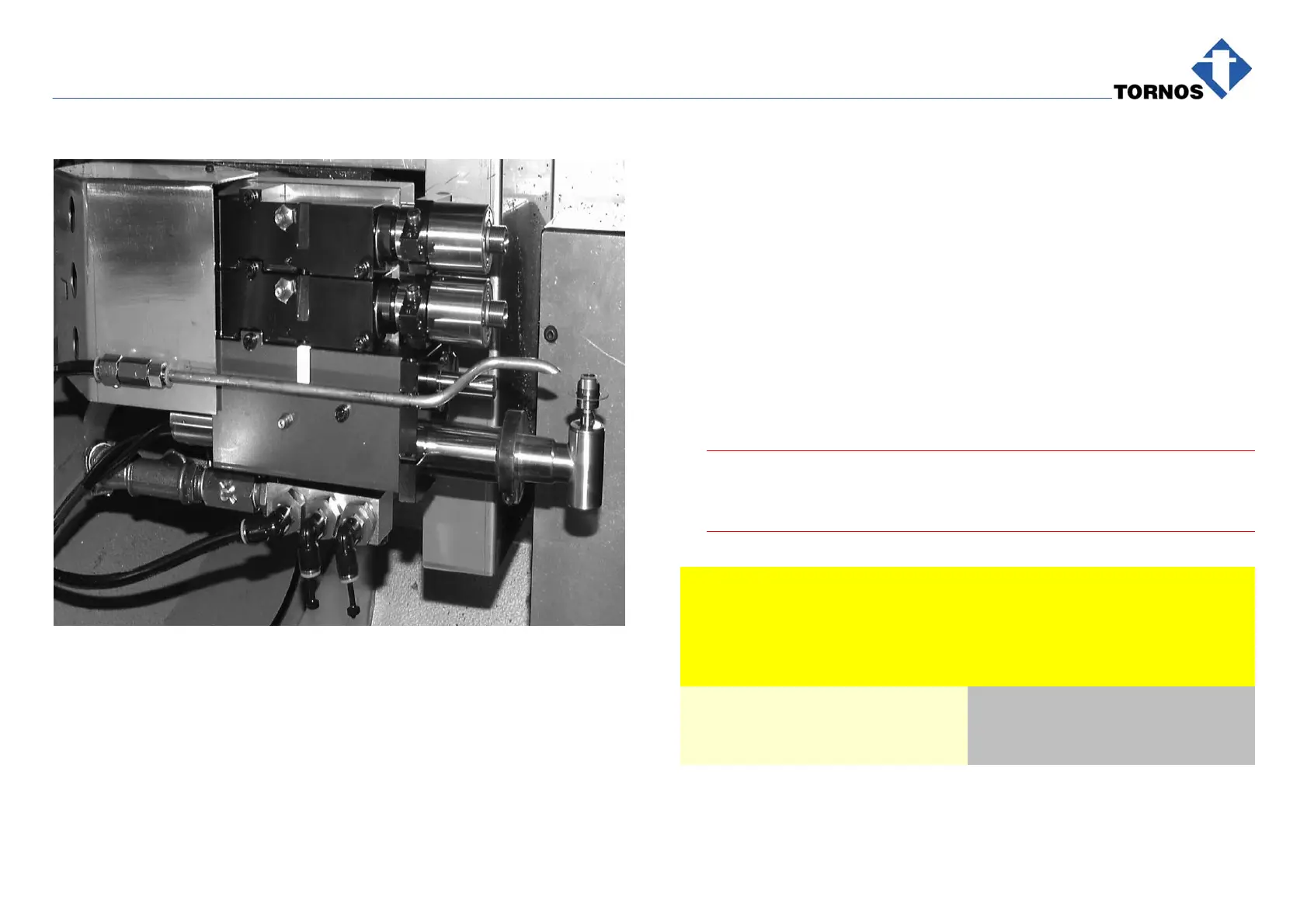

11.1 TECHNICAL DESCRIPTION

Fig. 1001 and 1002

The milling / slotting attachment operates in T33 only.

The body is located with two pins and two Screws 160 fasten it to the end

attachment. Inside the body, Sleeve 020 is fastened with Screw 150 and

driven with Fork 030. Inside the sleeve, the NSK spindle is fastened with

Screw 320.

The sleeve and the spindle to be positioned on setting up.

A guard for the cutter is fixed to the spindle.

The piping bracket to be positioned with Spacer 080 and Screw 170.

. Caution !

Air service pressure must not sink under 6 bar.The air pressure

required for good operation of the spindle is 5 bar.

11.2 MANUAL GREASING

Grease to use : See Instructions 300231, Para. 2.1.1.

Greasing interval : Grease every 6 months or at least every

1000 hours’ operation.

What to do ? How ? What for ? Notes

Grease through Nipple 300 ... until the grease comes out at

the sides.

Loading...

Loading...