OPTIONS & ALLIED TOOLING − DECO 7/10 − DECO 7a/10a − DECO 7e/10e

300236 en − 02/07 Chap. 12.2 /2

12.1 TECHNICAL DESCRIPTION

Mounting of drilling / milling attachment:

as gang tooling in X1 / Y1;

as gang tooling in X2 / Y2 possible but incompatible with S2 drive

Number of attachments, max. 2

The toolholder for the spindle is located with two pins on the baseplate and

fastened with two Screws 110.

. Caution !

Air service pressure must not sink under 6 bar.

The air pressure required for good operation of the spindle is 5 bar.

12.2 NSK SPINDLE

Fig. 1102

Operation and maintenance:

see the NSK NAKANISHI INC. supplier’s documentation, delivered with each

attachment.

Pneumatic drive: acc. to Diagram 305098 in Page 11/6

and Electrical Documentation 222 E 02 01

− Lubrication to be set at: 30 to 40 drops per minute

− The motor must not run without oil.

. Caution !

Wait about 2 minutes before the oil reaches the spindle.

Checking: Disconnect at spindle level and wait till oil arrives.

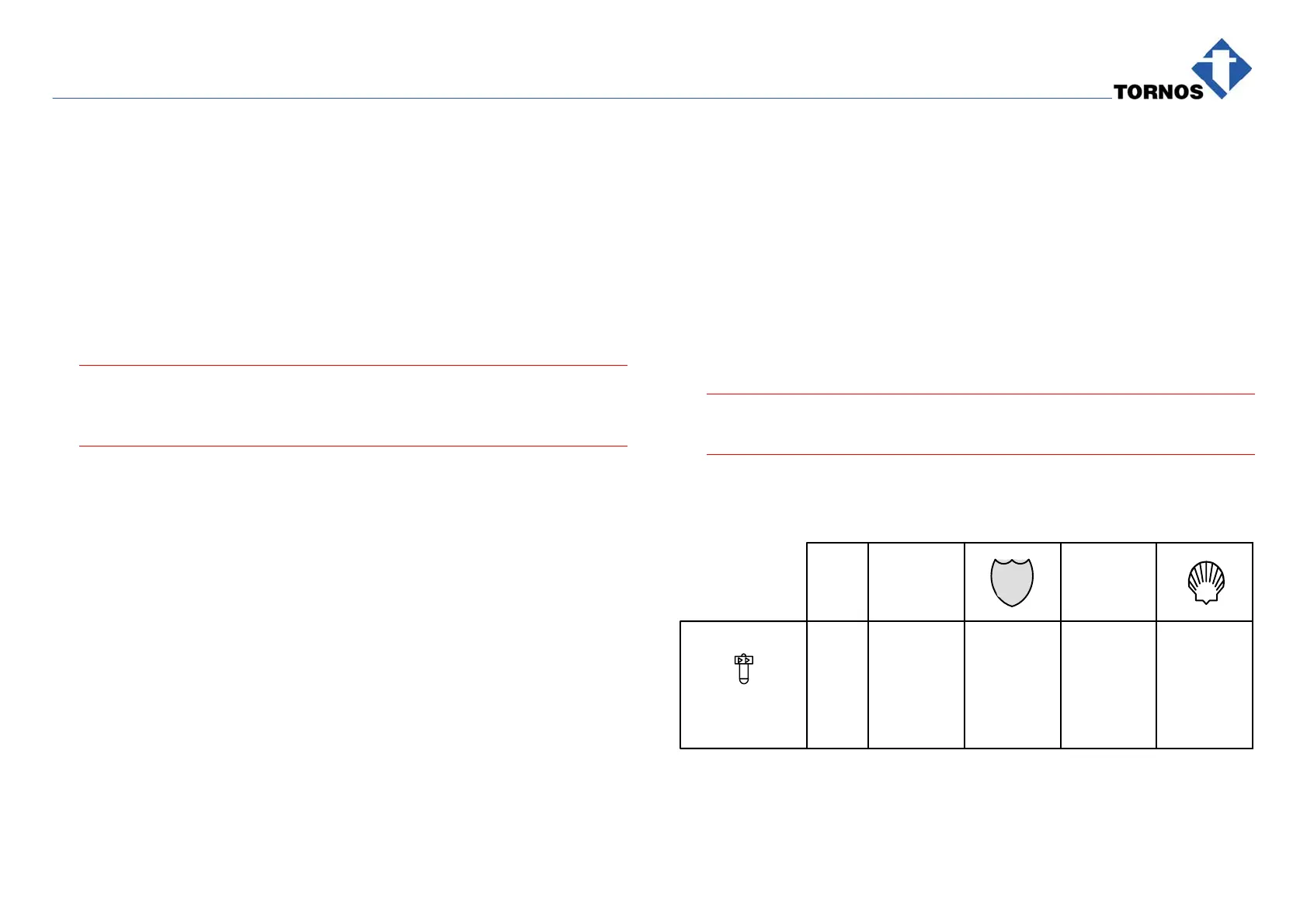

Oil: acc. to the table below.

ENERGOL

HLP−D10

TELLUS

OIL C 10

VELOCITE

OIL No. 6

DTE 21

Mobil

M

OTOREX

Pneumatics

Standard

COREX

EP D10

ISO 10

ISO−L−FD 10

BP

Loading...

Loading...