OPTIONS & ALLIED TOOLING − DECO 7/10 − DECO 7a/10a − DECO 7e/10e

300236 en − 02/07 Chap. 11.5 /9

11.5 OPERATION

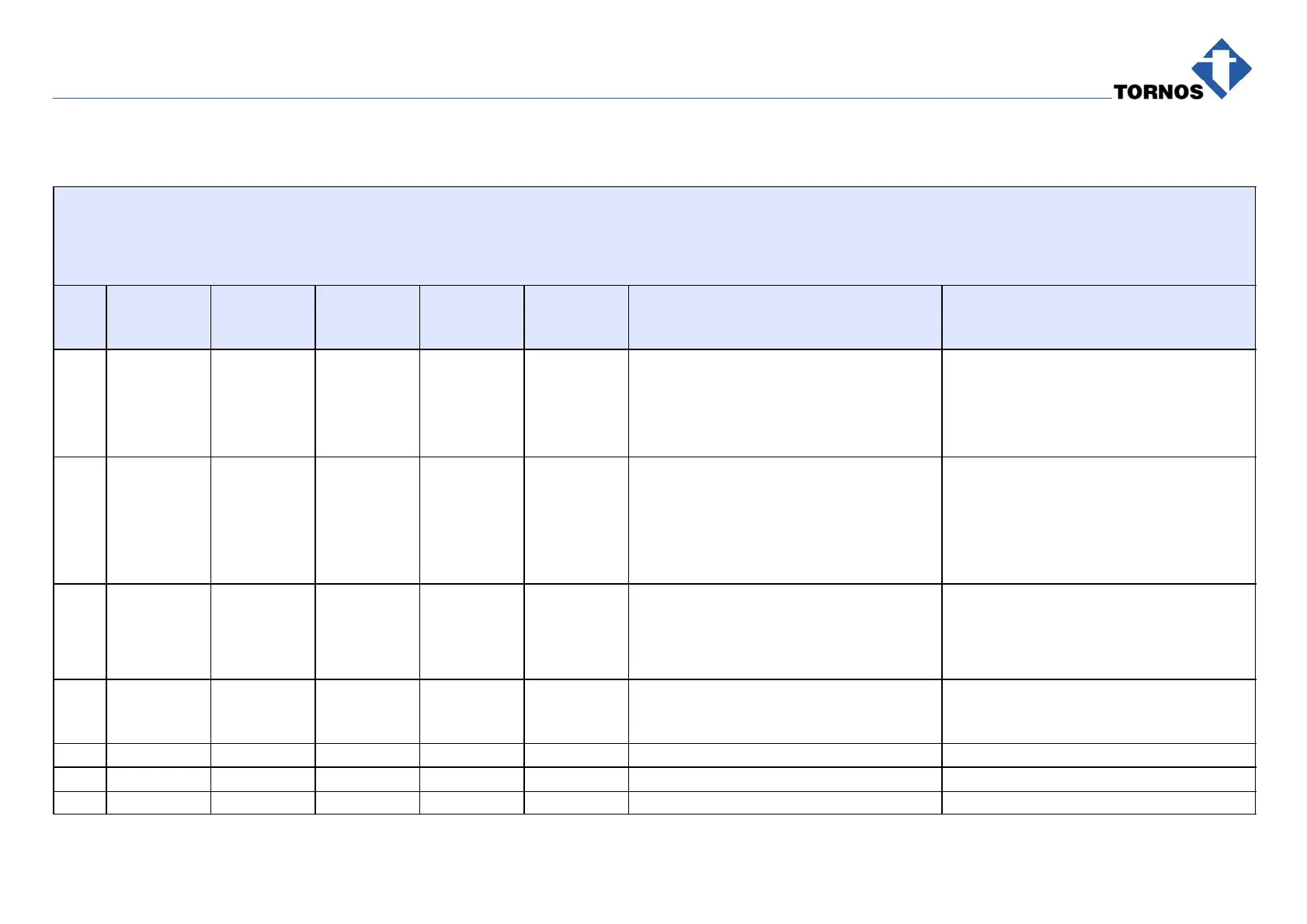

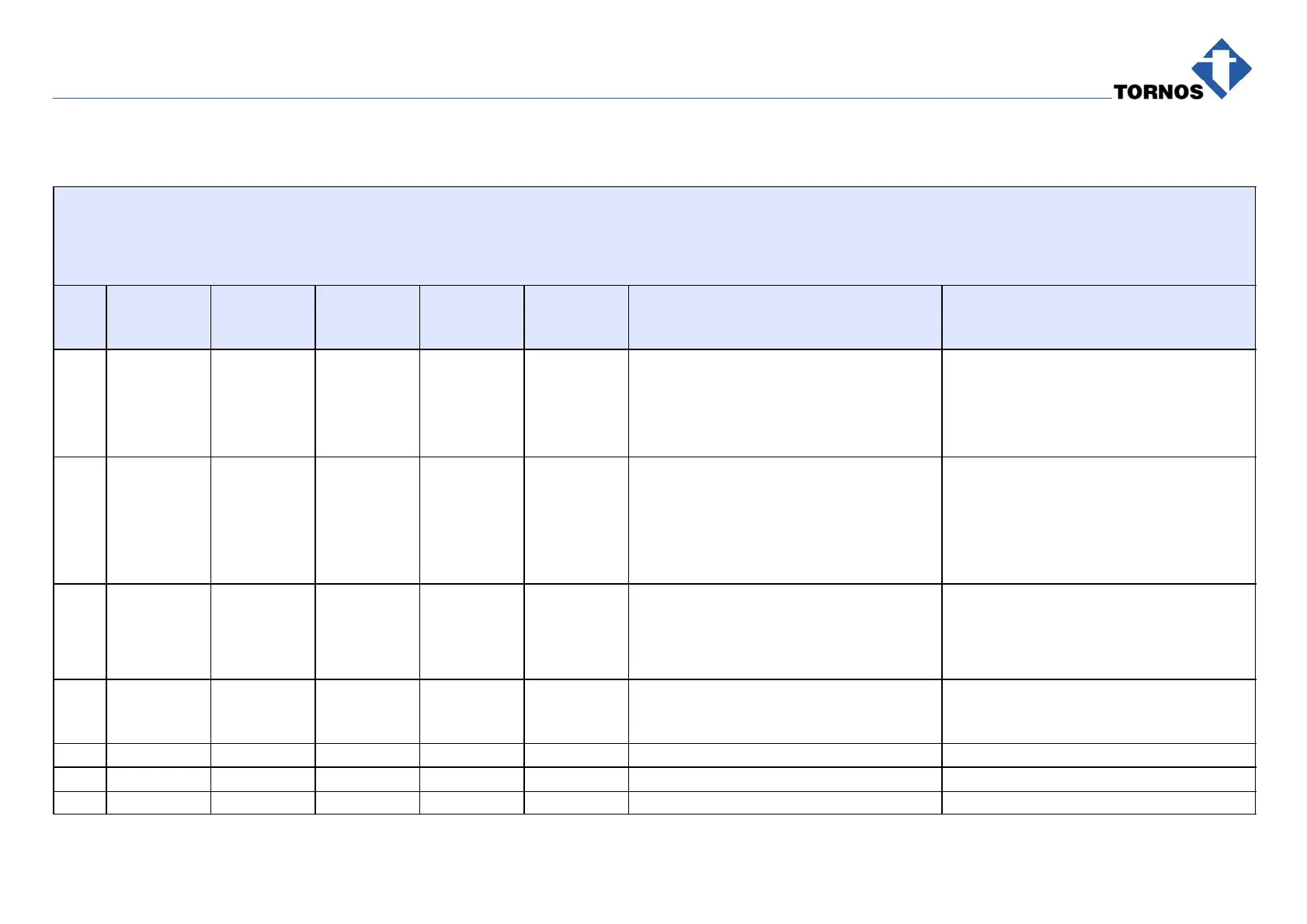

OPERATING RANGE OF NSK SPINDLE FOR MILLING ATTACHMENT MOUNTED IN T33

Attachment: AM−300 motor (30000 rpm) + RA−100 90° spindle (ratio 1:2.67; Theor. Speed 11235 rpm)

Stock: MS 58 A brass

Cutter: Ø 25 mm carbide slitting saw

Item

Cutter

thickness

[mm]

Milling

length

[mm]

Cutter

Ø

[mm]

Cutter

speed

[rpm]

Feedrate

max.

[mm/rev]

Comment Result

1 0.5 5 2 12000 0.1

Cross slotting for connectors, with cutter

stop before exit for 2nd cutting.

0.4 s dwell to allow cutter time to stop.

NOTE: Cutting in solid stock

OK, perfect milling surface quality.

600 parts machined without problem.

2 0.5 5 4 12000 0.03

Ditto, i.e. cross slotting in solid stock but

without stopping before cutter exit.

Bad!!!

With 70% of 0.1 mm/rev feedrate,

spindle slows down and cutter jams.

− Go down to 0.03 mm/rev to prevente

spindle for loosing too much speed.

3 0.5 5 6 12000 0.015

Ditto, i.e. cross slotting in solid stock but

without stopping before cutter exit.

OK

0.015 max. feedrate.

You can hear that spindle begins to

freeze on at the end of milling!

4 1 3 4 12000 0.015 Cross slotting (slots for screwdriver)

Maximum feedrate

Spindle begins to freeze on at the end

of milling.

5 1 5 4 12000 0.011 Cross slotting Maximum feedrate before freezing.

6 1 5 6 12000 0.0075 Cross slotting Maximum feedrate before freezing.

7 1.5 3 6 12000 0.005 Cross slotting Maximum feedrate before freezing.

Loading...

Loading...