OPTIONS & ALLIED TOOLING − DECO 7/10 − DECO 7a/10a − DECO 7e/10e

300236 en − 02/07 Chap. 11.5 /10

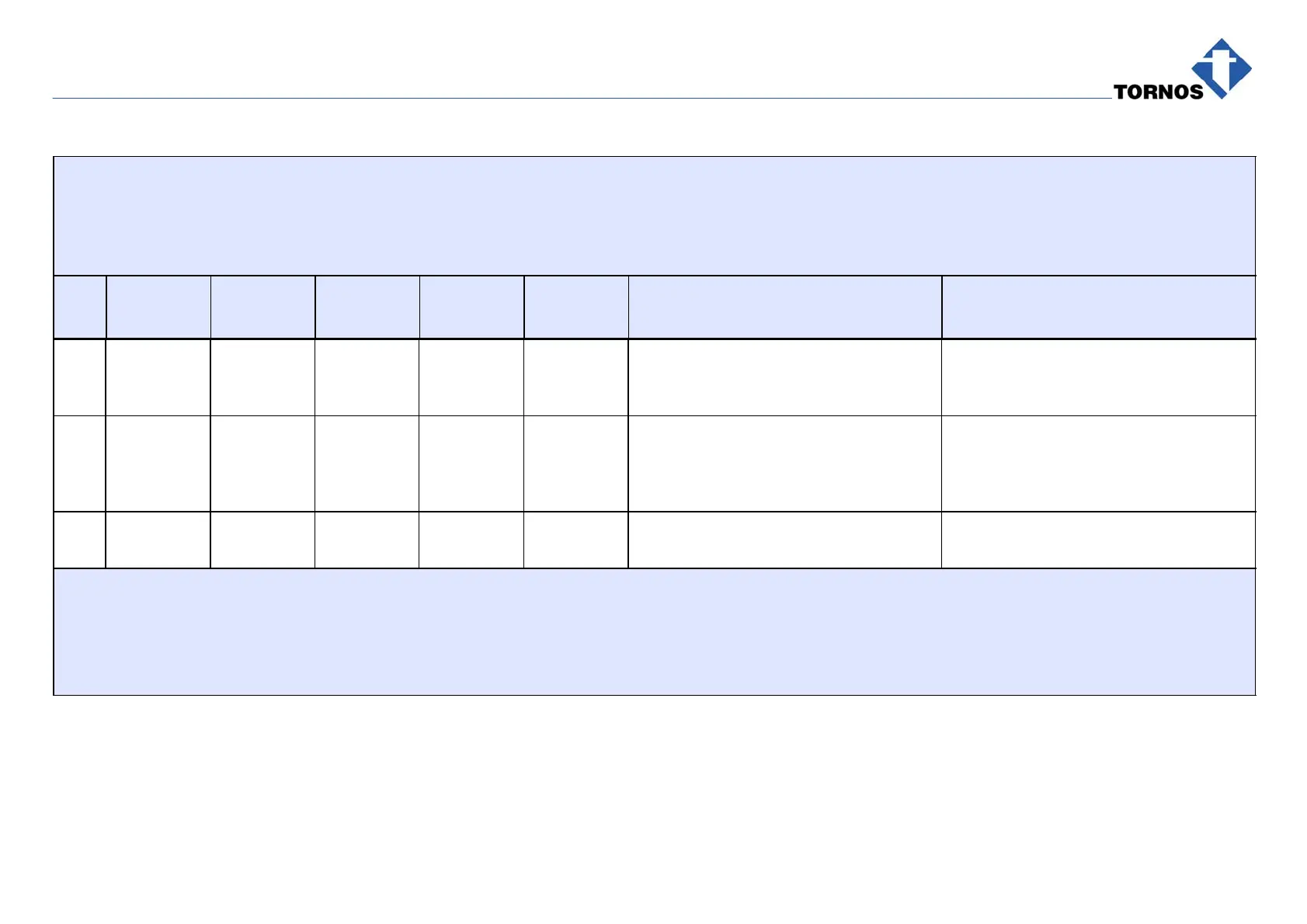

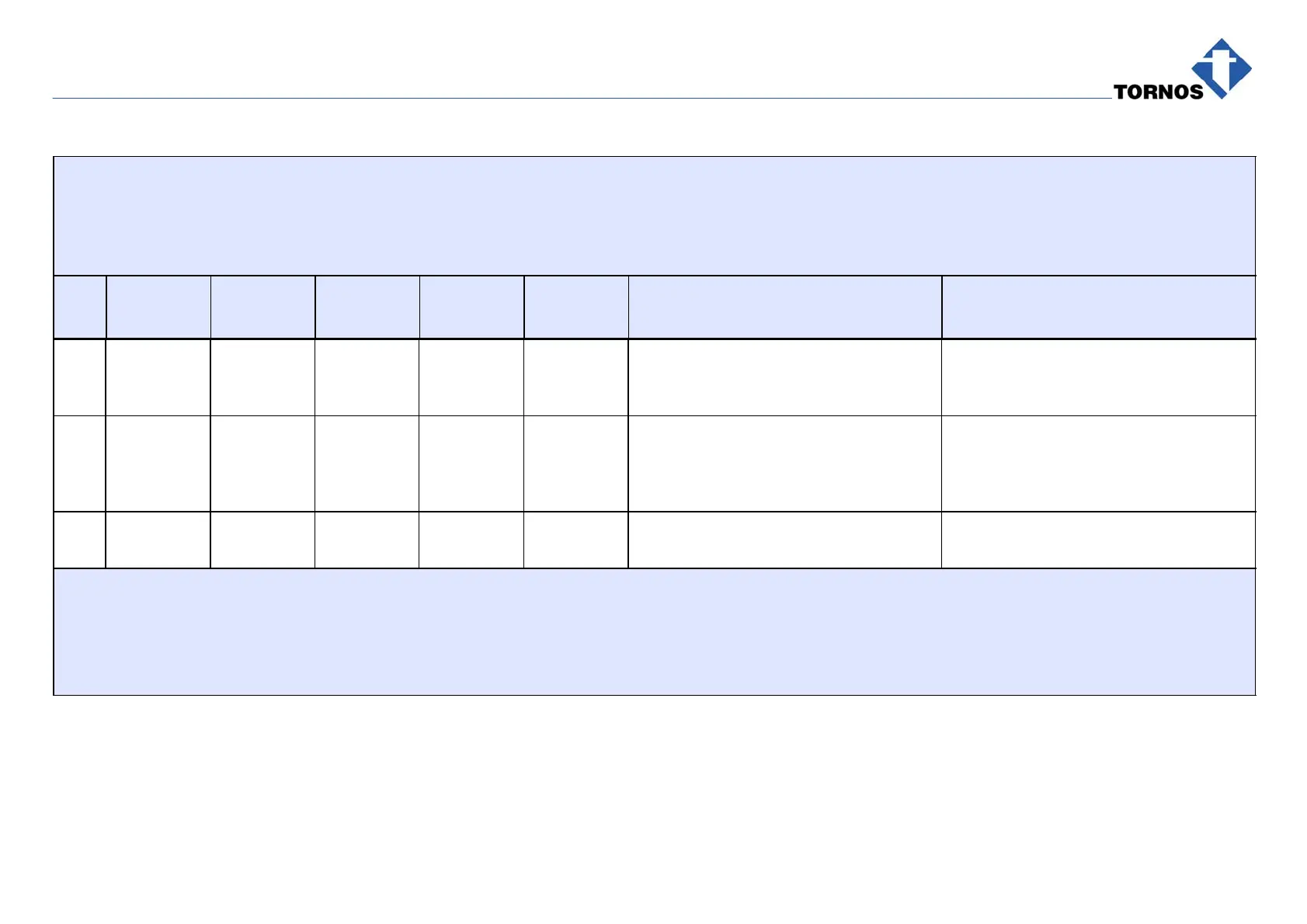

OPERATING RANGE OF NSK SPINDLE FOR MILLING ATTACHMENT MOUNTED IN T33

cont.

Attachment: AM−300 motor (30000 rpm) + RA−100 90° spindle (ratio 1:2.67; Theor. Speed 11235 rpm)

+ ARG−01 speed reducer (Ratio 1:3.92; theor. speed 2866 rpm)

Stock: MS 58 A brass

Cutter: Ø 35 mm carbide slitting saw

Item

Cutter

thickness

[mm]

Milling

length

[mm]

Cutter

Ø

[mm]

Cutter

speed

[rpm]

feedrate

max.

[mm/rev]

Comment Result

12 0.5 6 2 12000 0.015 Cross slotting

Maximum feedrate before freezing.

Over 0.02 mm/rev, cutter jams because

it is seized by slot edges.

13 0.5 10 2 12000 0.1

Cross slotting

Note: A higher feedrate (0.1 mm/rev)

is better because 10 mm can be cut

due to inertia without problems.

OK, no spindle freezing.

Below 0.1 mm/rev, slot edges seize

cutter from 6 mm length on.

14 0.5 10 2.8 12000 0.1 Cross slotting

Bad!

Cutter vibrates on 2.8 mm Ø.

Conclusion:

It is very difficult to determine the operating range of the attachment.

The best way is to start cutting at a low feedrate and to accelerate progressively while listening to the noise produced by the

NSK spindle.

Loading...

Loading...