OPTIONS & ALLIED TOOLING − DECO 7/10 − DECO 7a/10a − DECO 7e/10e

300236 en − 02/07 Chap. 13.5 /4

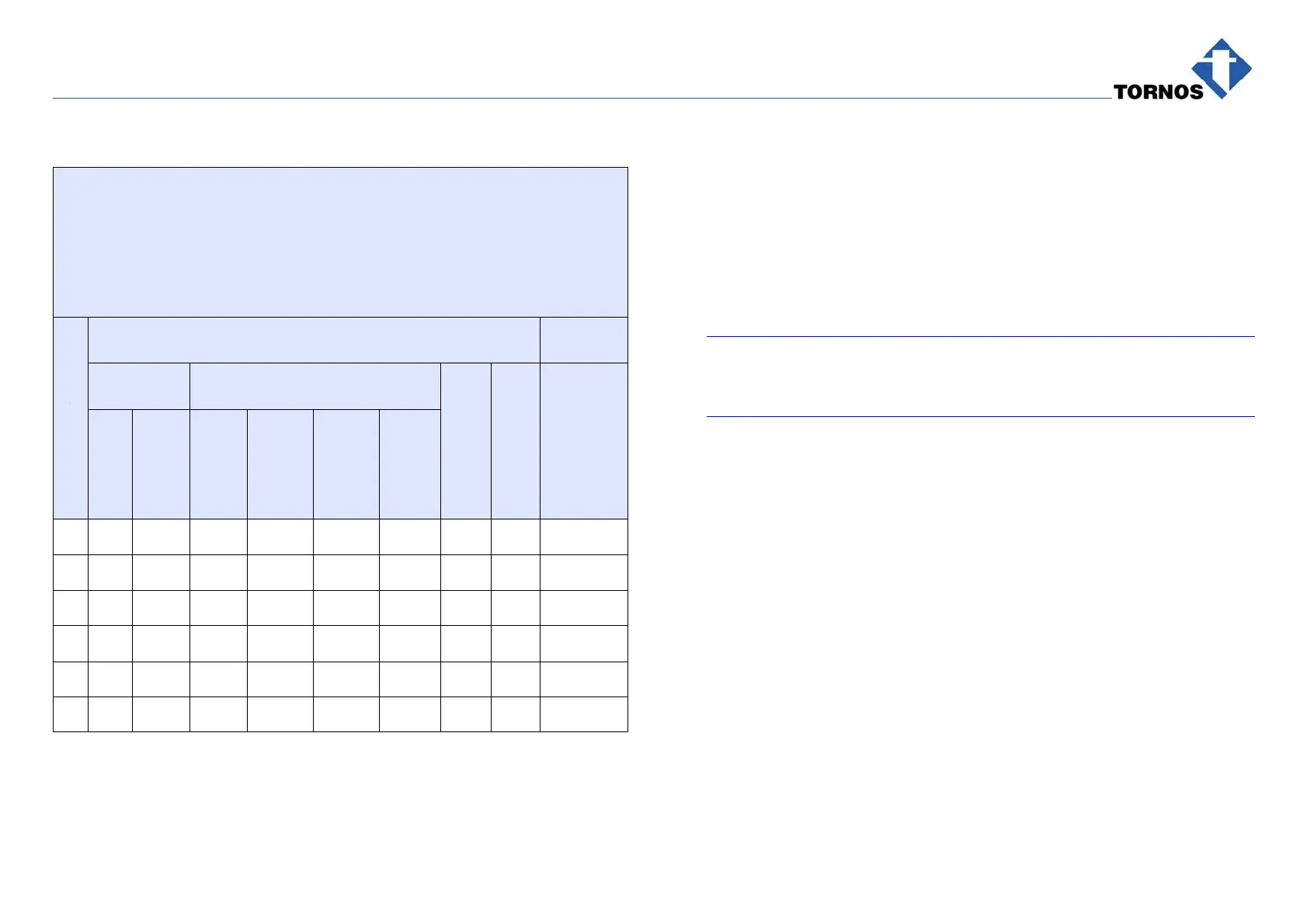

13.4 TESTS FOR DIFFERENTIAL THREADING ON S1/S3

Stock : Brass − MS−58 A

Diameter : 7 mm

Results : for machining approx. : 50 pcs in Tests No. 1, 3, 4, 5, 6

75 pcs in Test No. 2

Thread length measurement : with gauge

TECHNICAL DATA

RESULTS

o.

Speed [rpm]

tio

Test

∅

Lengt

[mm]

S1

S3

thread-

ing

S3

thread-

ing off

Die

head

Actual

speed

Threading

Spring forc

[kg]

Disper-

sion

in length

[mm/pcs]

1

M4 30 9000 8000 10000 1000 8 2 0.44 / 50

2

M4 10 9000 8000 10000 1000 8 2 0.20 / 75

3

M2 10 9000 7500 10500 1500 5 1 0.13 / 50

4

M1 6 9000 7500 10500 1500 5 1 0.10 / 50

5

M1 6 9000 6000 12000 3000 2 1 0.08 / 50

6

M1 6 11500 11000 12000 5000 22 1 0.12 / 50

13.5 CALCULATING THREADING RATIO

Calculate a THREADING RATIO as follows :

− S1 speed / S3 speed for threading : 9000 / 8000 = 1.125

− Subtract 1 : 1.125 − 1 = 0.125

− 1 / x : 1 / 0.125 =

8

Note :

Ratio 8 means that 8 revolutions of the part per 1 revolution of the die

head are required.

An example for DWELL CALCULATION, see Instructions 300232 : PRO-

GRAMMING.

Loading...

Loading...