TestProcedure(continued)

3.ReadallWarning,Cautions,andprecautionslistedatthebeginningofthis

section.

4.Raiseandsupporttheoperatorseat,removetheseatplatetogetaccessto

thehydraulicpumpassembly.

5.EnsurethatthetractionpedalisintheNEUTRALposition,thesteeringwheel

isstationaryandparkingbrakeisset.

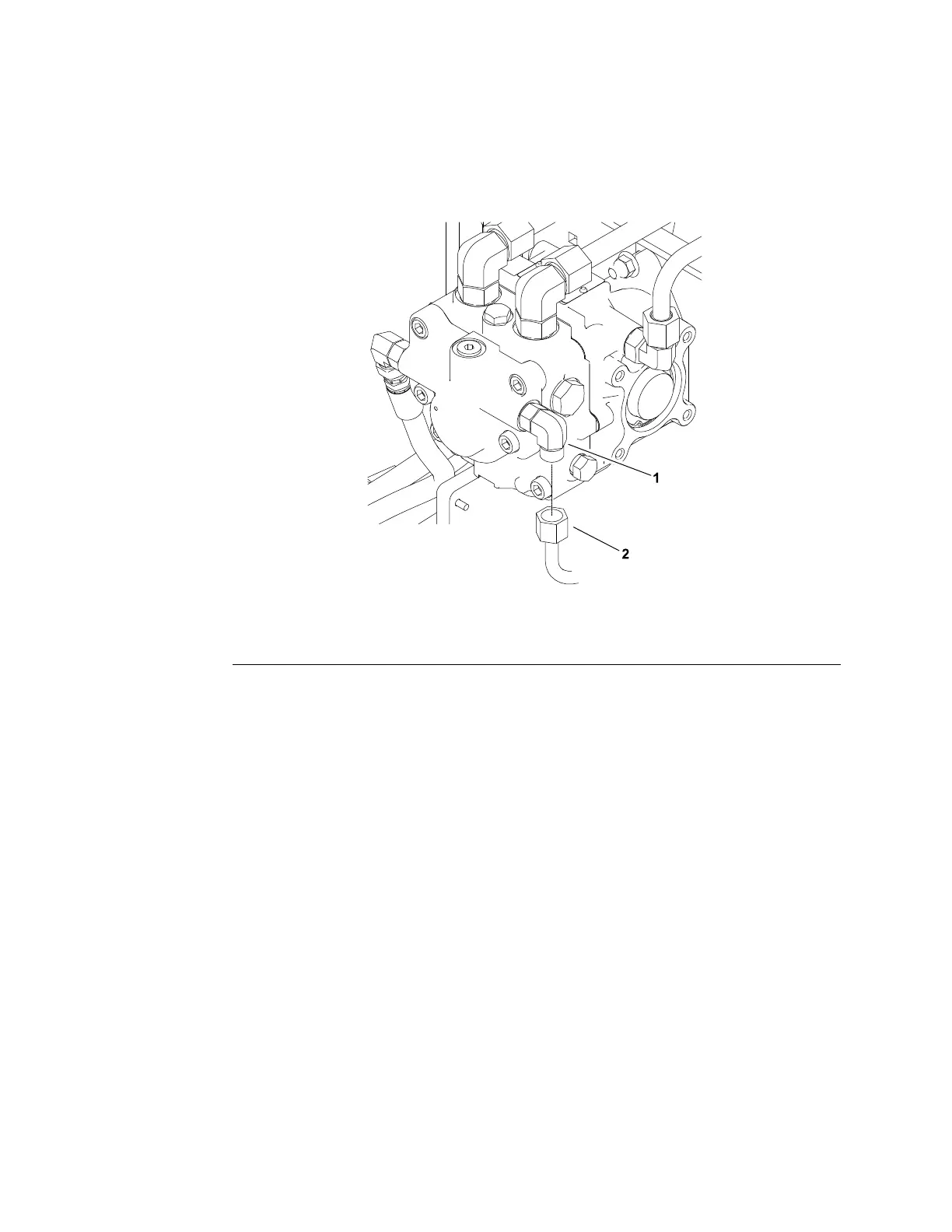

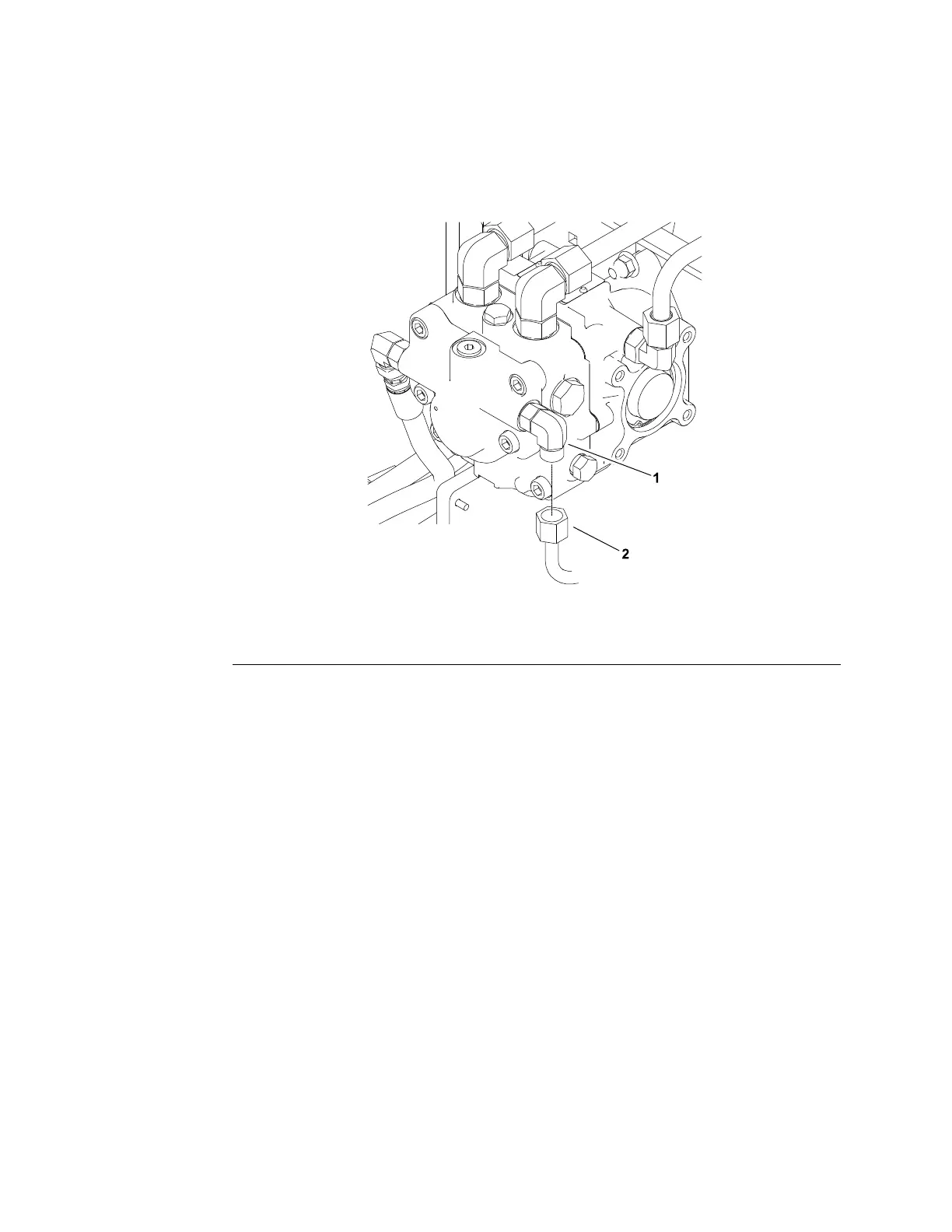

g226949

Figure68

1.90°hydraulictting

2.Hydraulictube

6.Cleanthettingandhydraulictube(Figure68).Loosenandremovethetube

fromthetting.Installateettingwitha35,000kPa(5,000psi)pressure

gaugebetweenthettinganddisconnectedtube.

7.Attachaheavychaintotherearofthemachineframeandanimmovable

objecttopreventthemachinefrommovingduringtesting.

8.Blockthewheelswithchockstopreventthewheelrotationduringtesting.

9.Starttheengineandmovethethrottletofullspeed(3,100to3,250rpm)

position.Useatachometertocheckthattheenginespeediscorrect.

10.Recordthereadingonthechargecircuitpressuregauge.Thecharge

pressure(withoutload)shouldread345to483kPa(50to70psi).Ifthe

chargereliefpressurespecicationisnotmet,considerthefollowing:

A.Thehydraulicpumpchargereliefvalveisdamaged.Repairorreplace

thehydraulicpumpchargereliefvalve;refertoServicingtheHydraulic

Pump(MachineSerialNumberabove316000000)(page5–103).

11.Sitintheoperator’sseat,releasetheparkingbrake,andslowlypressthe

tractionpedalforwarduntil8,963to13,100kPa(1,300to1,900psi)is

reachedonthetractioncircuitpressuregauge.

HydraulicSystem:TestingtheHydraulicSystem

Page5–60

Groundsmaster

®

3280-D/3320

05138SLRevB

Loading...

Loading...