TestProcedure

Note:Whenperformingtheliftcylinderinternalleakagetest,thecuttingdeck

shouldbeattachedtotheliftarms.

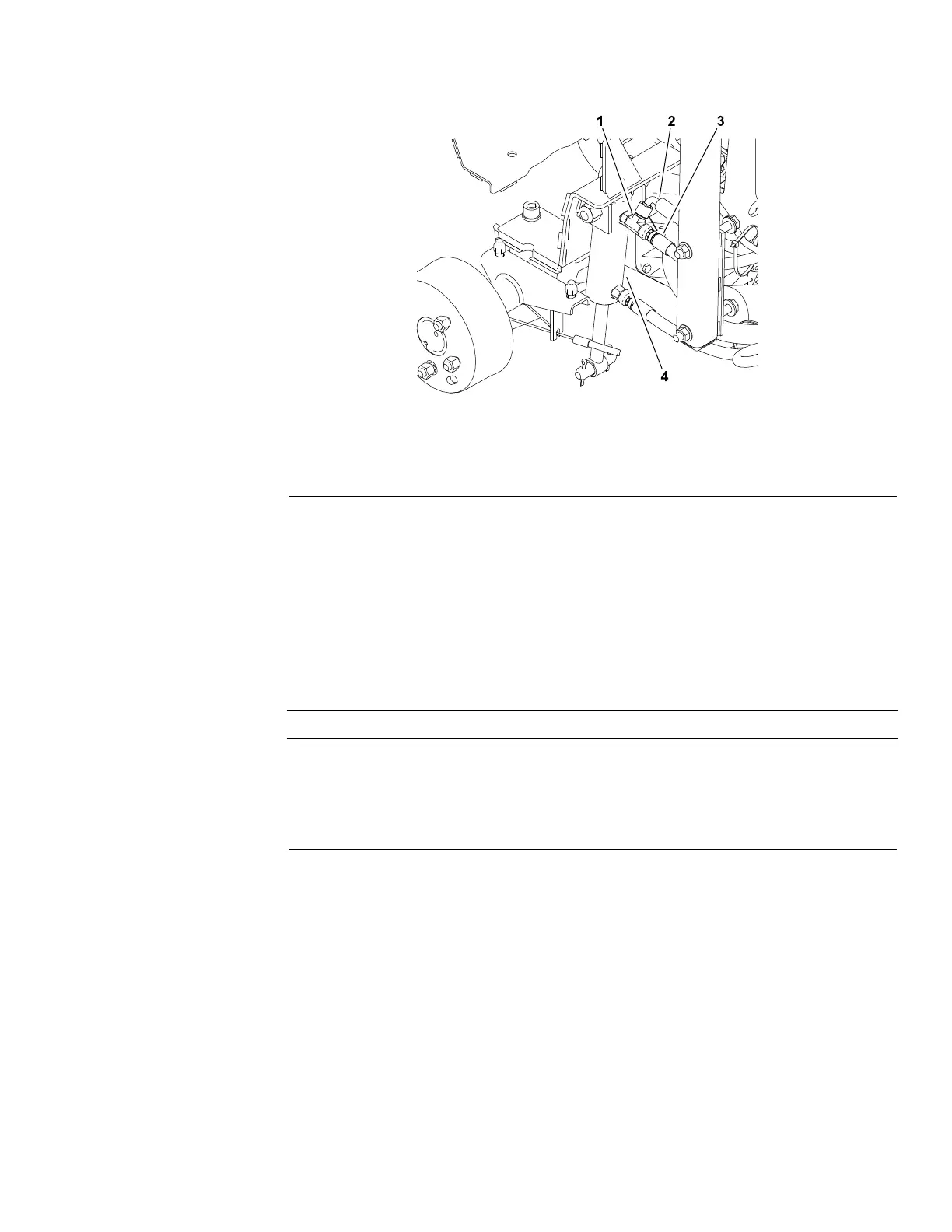

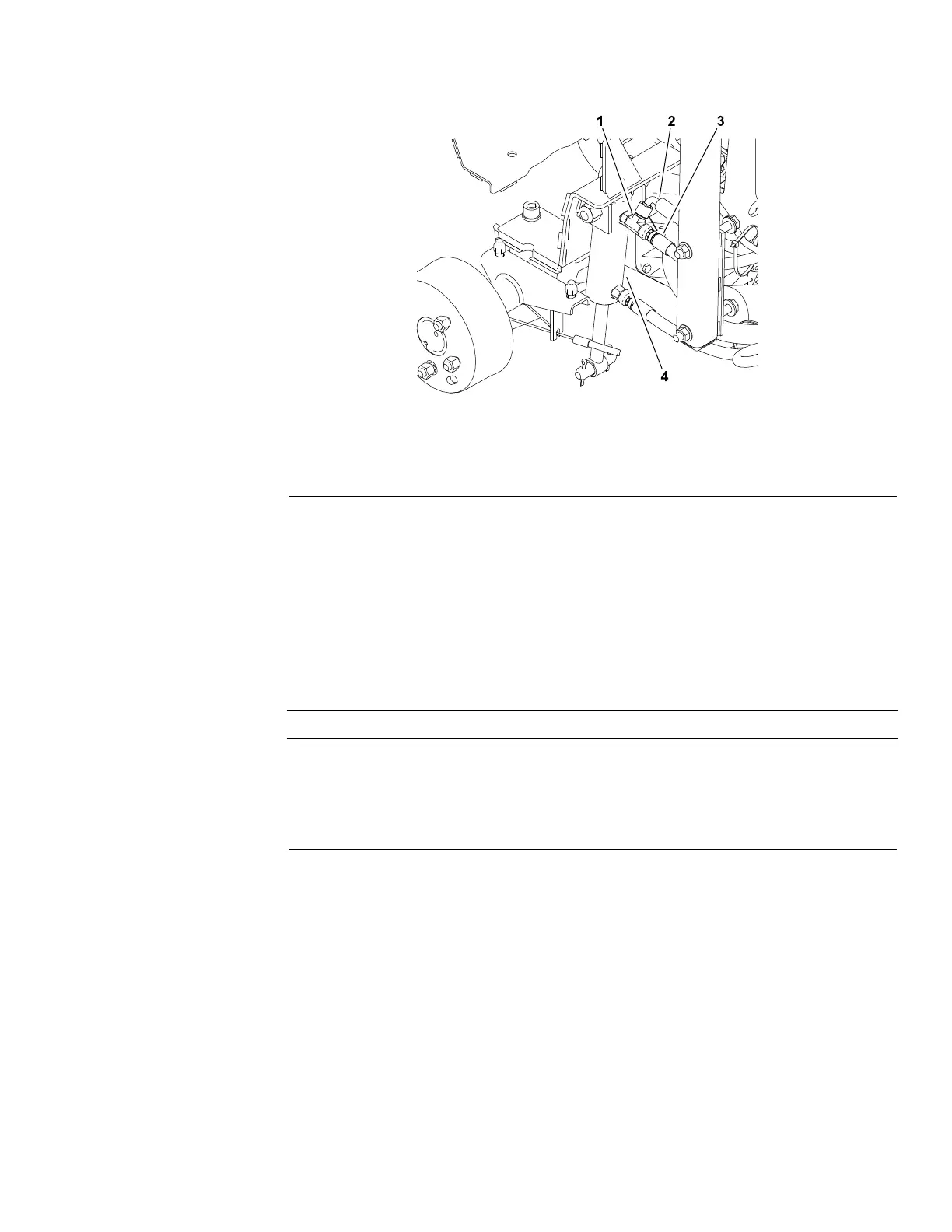

g225791

Figure74

1.Cylinderbarrelendtting

3.Hydraulichose

2.Hydraulichose

4.Liftcylinder

1.ParkthemachineonalevelsurfacewiththePTOswitchoff,shutoffthe

engine,andsettheparkingbrake.

2.Fortheliftcylinderthatistobetested,useajacktoraisetheliftarmslightly.

Thisremovestheloadfromtheliftcylinderandreleasestheliftcylinder

hydraulicpressure.

3.Supporttheliftarmwithjackstandstopreventitfromlowering.

4.Cleantheareaaroundthehydraulichosesendatthebarrelendofthelift

cylinder.Disconnectthehydraulichosesfromtheliftcylinderbarrelend

tting(Figure74).

IMPORTANT

Whencappingtheliftcylinderttingandhydraulichoseend,use

asteelcapandplugtoensurethatthereisnouidleakage.The

plasticplugscannotholdthehydraulicpressurethatisdeveloped

duringthistestprocedure.

5.Installasteelcapontheopenliftcylinderttingtosealtheliftcylinder.Also,

installasteelplugintheopenendofthedisconnectedhosetoprevent

leakageorcontamination.

6.Raisetheliftarmslightlywithajackandremovethejackstand,thenlower

andremovethejack.

7.Thecappedliftcylindershouldbeabletosupportthecuttingdecklong

enoughforthemachinetomovefromonecuttingareatoanotherduring

operation.

8.Iftheliftcylinderallowsthecuttingdecktolowertooquickly,replaceorrepair

theliftcylinder;refertotheLiftCylinder(page5–110).

9.Oncetheliftcylinderconditionisdetermined,useajacktoraisetheliftarm

slightlywhichremovestheloadfromtheliftcylinder.

10.Supporttheliftarmwithjackstandstopreventitfromlowering.

Groundsmaster

®

3280-D/3320

Page5–73

HydraulicSystem:TestingtheHydraulicSystem

05138SLRevB

Loading...

Loading...