DisassemblytheLiftControlValve(continued)

5.CarefullyremoveO-rings(item4inFigure104)fromspoolbore.Takecare

nottodamagespoolboreorO-ringcavitiesduringO-ringremoval.

6.Removedetentplug(item16inFigure104),O-ring,spring,anddetentball.

7.Removeplug(item9inFigure104)withO-ring,andlockoutseatwithO-ring

fromvalvebody.

8.Removeadapterplug(item14inFigure104)withO-ring,poppetstop,

spring,andpoppetfromcontrolvalvebody.

9.Removelockoutseat(item22inFigure104)withO-ringfromcontrolvalve

body.Removedetentplunger.

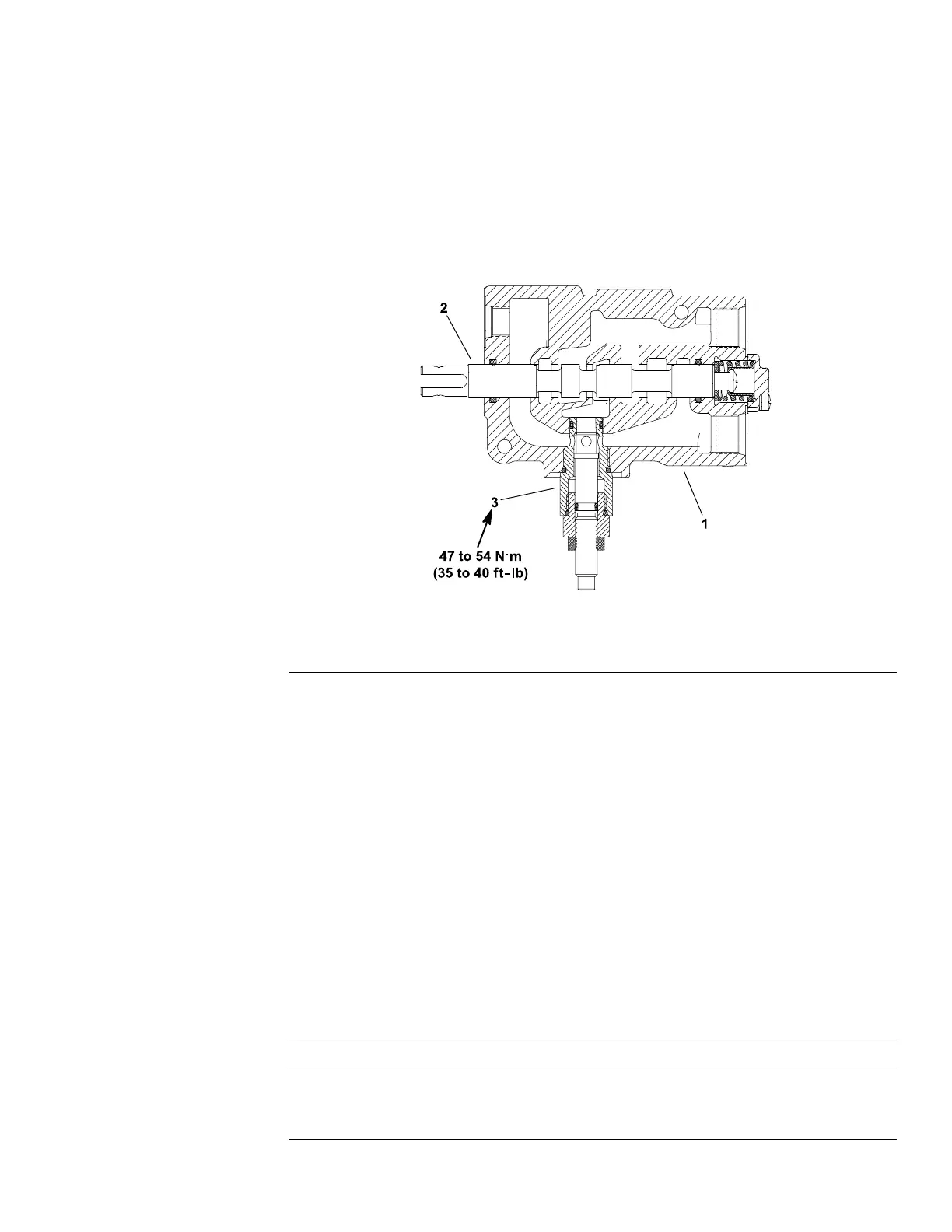

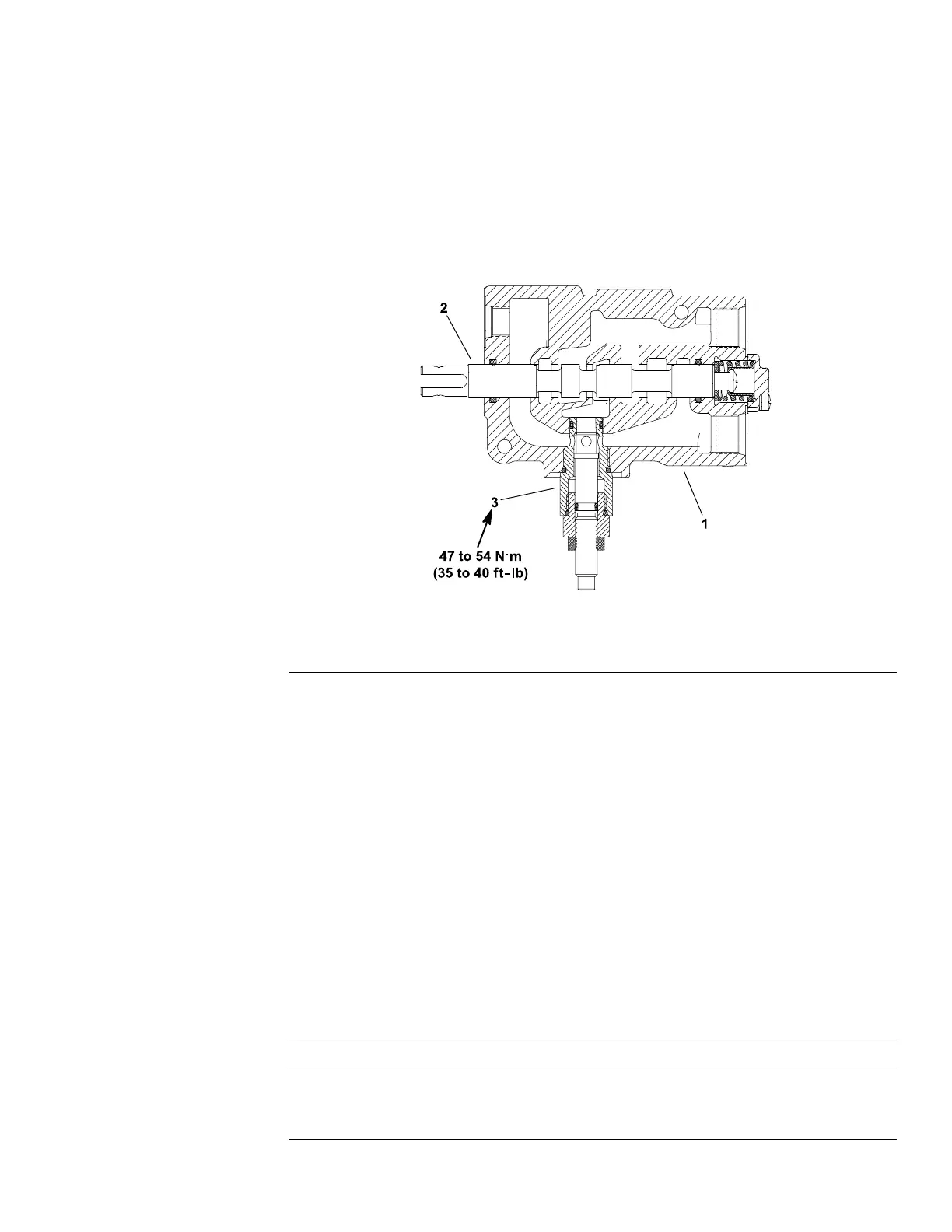

g230844

Figure105

1.Liftcontrolvalve2.Spool3.Counterbalancevalve

10.Ifcontrolvalveisequippedwithcounterbalancevalve(Figure105),remove

valvefromcontrolvalveifnecessary.Counterbalancevalvedisassembly

isnotrecommended.

InspectingtheLiftControlValve

1.Inspectspoolandspoolboreforwear.Ifwearisexcessive,replacelift

controlvalveassembly.

2.Inspectallspringsandreplaceifdamagedorbroken.

3.Inspectdetentplunger,detentball,andpoppetforwear.Replaceas

necessary.

4.Inspectlockoutseatsforwearordamage.Replaceasnecessary.

5.InspectcontrolvalvehousingthreadsandO-ringsealingsurfaces.Replace

asnecessary.

6.InspectthreadsandO-ringsealingsurfacesonplugs.Replaceasnecessary.

AssemblingtheLiftControlValve

IMPORTANT

Donotwipepartswithdrypapertowelsorrags.Lintmaycause

damagetothehydraulicsystem.

Groundsmaster

®

3280-D/3320

Page5–131

HydraulicSystem:ServiceandRepairs

05138SLRevB

Loading...

Loading...