InstallingtheInputShaft/PinionGear(4-WheelDriveAxle)(continued)

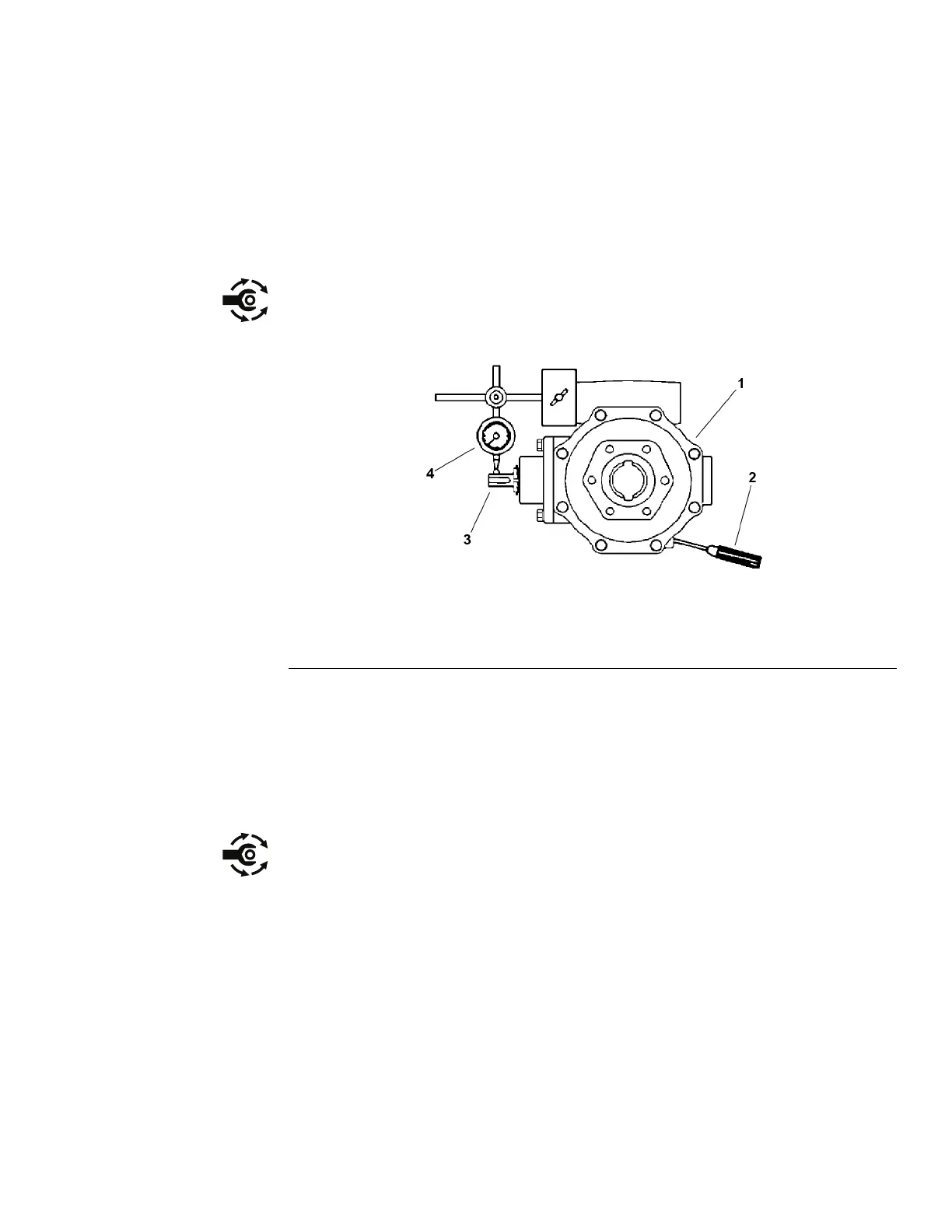

9.Useadepthgaugetomeasurethedistancefromtheendfaceoftheinput

shaft/piniongeartothematingsurfaceofthebearingcase.Subtractthe

designconecenterdistancefromthisdistancetodetermineinitialshim

thickness(Figure273).

Designconecenterdistance(distancefrommatingsurfaceoftheaxle

supporttotheendfaceofthepiniongear):47.50±0.05mm(1.870±0.002

inch)

Note:Bearingcaseshimsareavailablein0.10mm(0.004inch)and0.20

mm(0.008inch)thickness.

10.CoatanewO-ringwithgrease.Placeshimsonthebearingcaseand

temporarilyinstalltheinputshaft/piniongearassemblyintotheaxlecase.

Tightenthemountingscrewsto47to56N·m(35to41ft-lb).

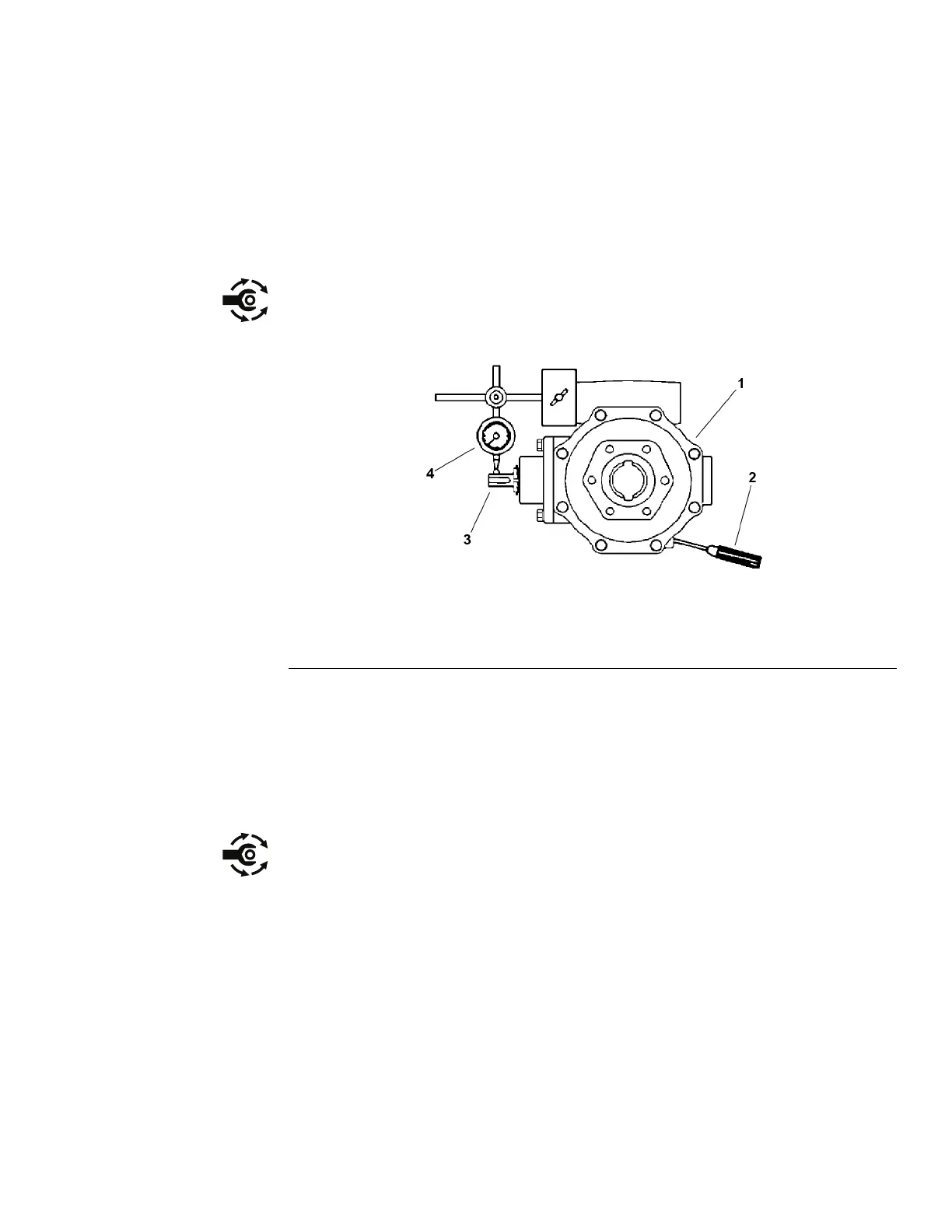

g226492

Figure274

1.Axlecase

3.Inputshaft/piniongear

2.Screwdriver

4.Dialindicator

11.Insertascrewdriverthroughthedrainplugholetoholdtheringgearand

measurethepiniongeartoringgearbacklash(Figure274).

Piniongeartoringgearbacklash:0.10to0.40mm(0.004to0.016inch)

12.Adjustbacklashbyincreasingorreducingthebearingcaseshimthickness.

13.Checkthepiniongeartoringgearengagement;refertoPinionGeartoRing

GearEngagement(4-WheelDriveAxle)(page8–70).

14.Placethecorrectcombinationofshimsonthebearingcase.Tightenthe

mountingscrewsto47to56N·m(35to41ft-lb).

Groundsmaster

®

3280-D/3320

Page8–63

DriveAxles:ServiceandRepairs

05138SLRevB

Loading...

Loading...