7-12 SHB WL34 * 2.0

7 Steering system

Steering hydraulics

7.7 Checking the steering hydraulics

Preparing work

Tools:

• Test pressure gage 0 – 600 bar

• T fitting

• Plugs (different sizes) for closing the oil lines

Use a suitable container to collect the hydraulic oil as it drains off and

dispose of it in an environmentally friendly manner!

Checking the steering pressure

1. Put the loader unit in the lowest position.

2. Release the pressure in the hydraulic system – see “Releasing

residual pressure in the hydraulic system” on page E-32.

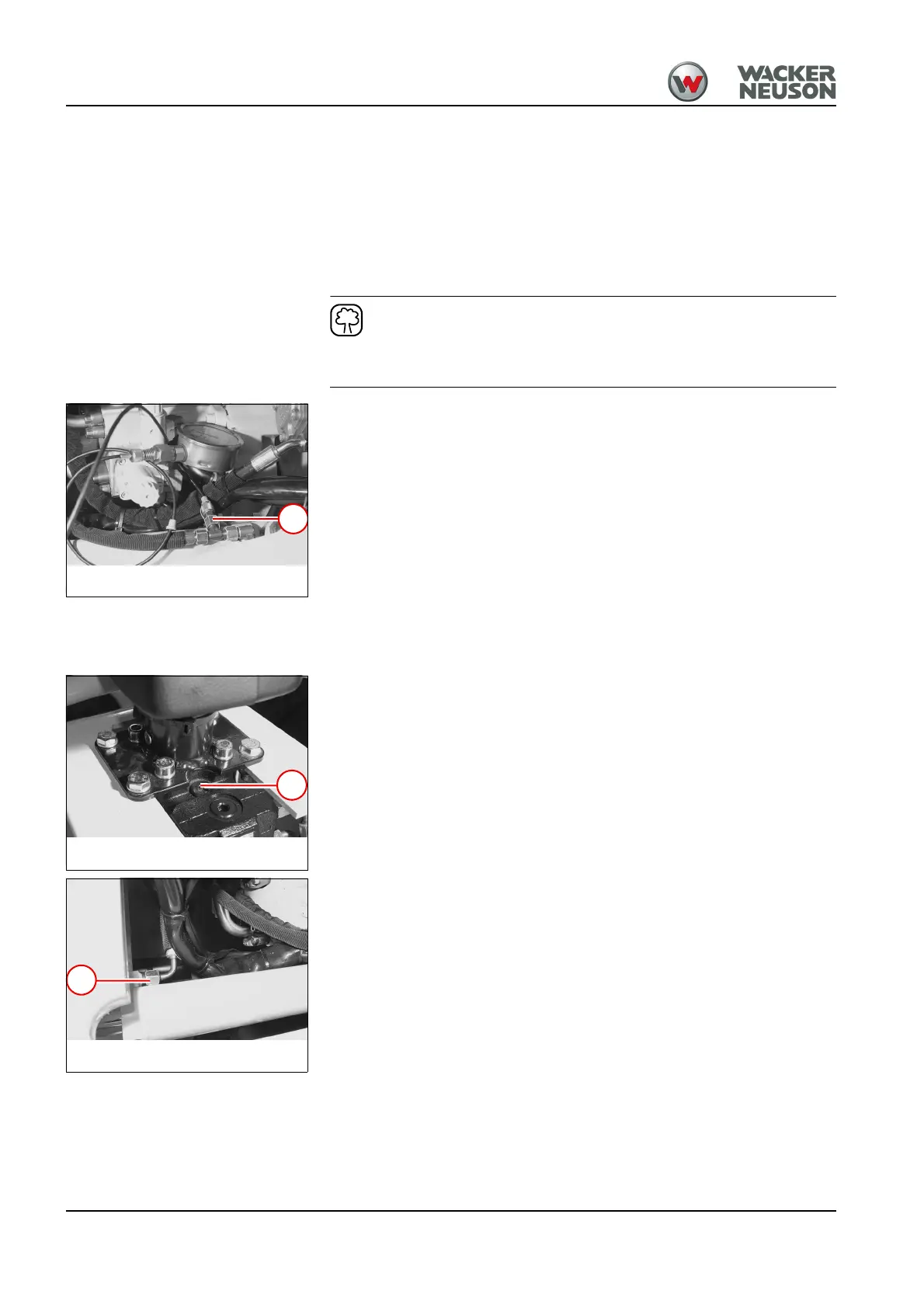

3. Install the T-fitting 1 and the test adapter in the base-side hydraulic line

of the steering cylinder.

4. Connect the test pressure gage 0 – 600 bar.

5. With the engine running, turn the steering wheel clockwise until the

articulation is at the limit.

6. Read the steering pressure off the test pressure gage (specified value:

190 bar).

7. If the steering pressure differs from the specified value, adjust the

steering pressure.

Adjusting the steering pressure

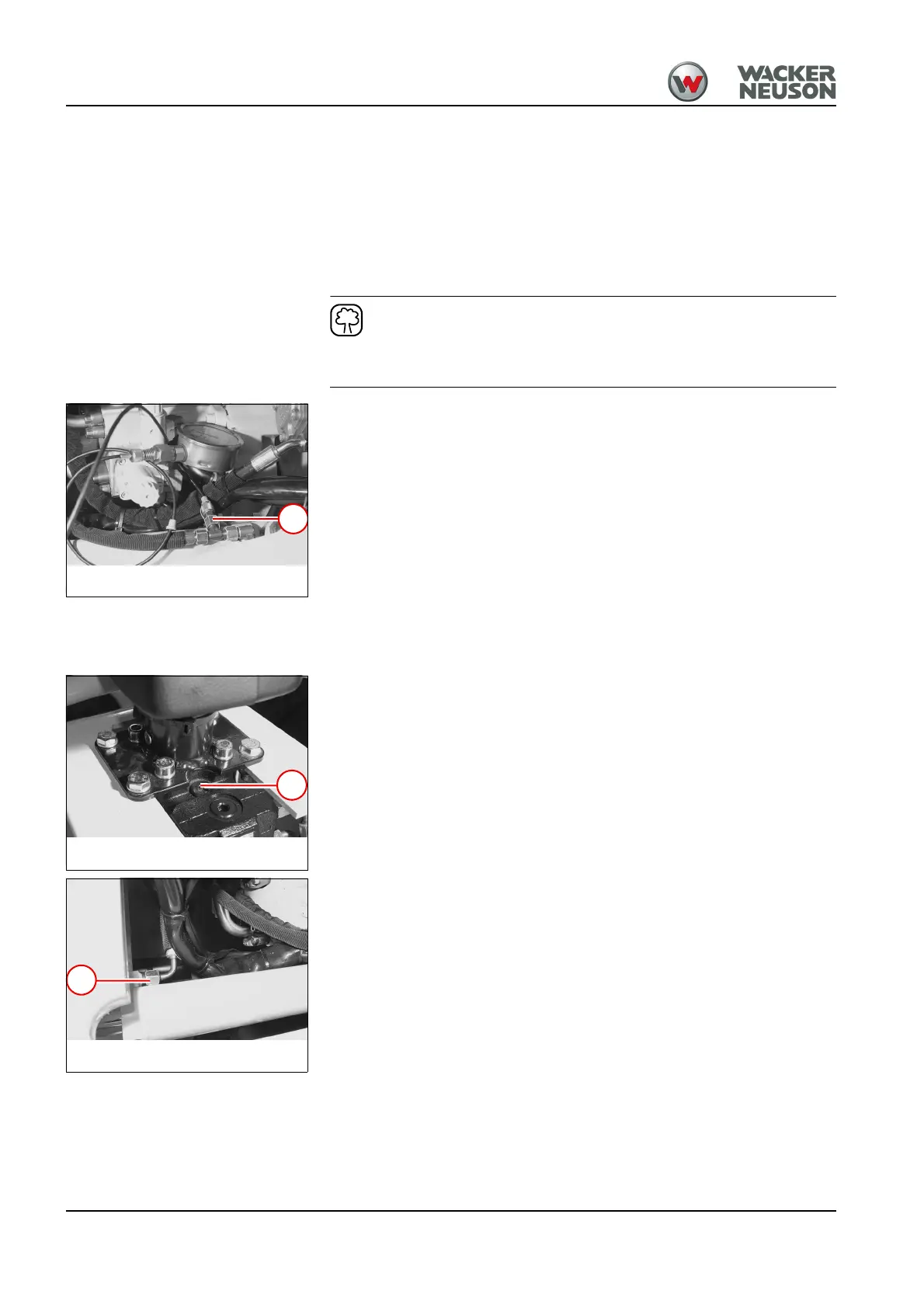

1. Remove screw connection 1.

2. Adjust the steering pressure with the screw below it:

➥ Turn the screw clockwise: the pressure increases.

➥ Turn the screw anticlockwise: the pressure decreases.

3. Screw in and tighten the screw connection.

Checking the steering cylinder for internal leakage

1. Extend the steering cylinder completely.

2. Unscrew the rod-side hydraulic line 1 and close it.

3. Leave the hydraulic connection on the steering cylinder open.

4. With the engine running, continue turning the steering wheel

clockwise.

5. If oil comes out of the hydraulic connection, replace the steering

cylinder.

Checking the emergency steering features

1. With the engine stopped, turn the steering wheel clockwise or

anticlockwise until the articulation is at the limit.

2. If the steering wheel can be steered beyond the limit, replace the

steering orbitrol – see “Removing/installing the steering orbitrol” on

page 7-10.

Steering system

Steering hydraulics

Loading...

Loading...