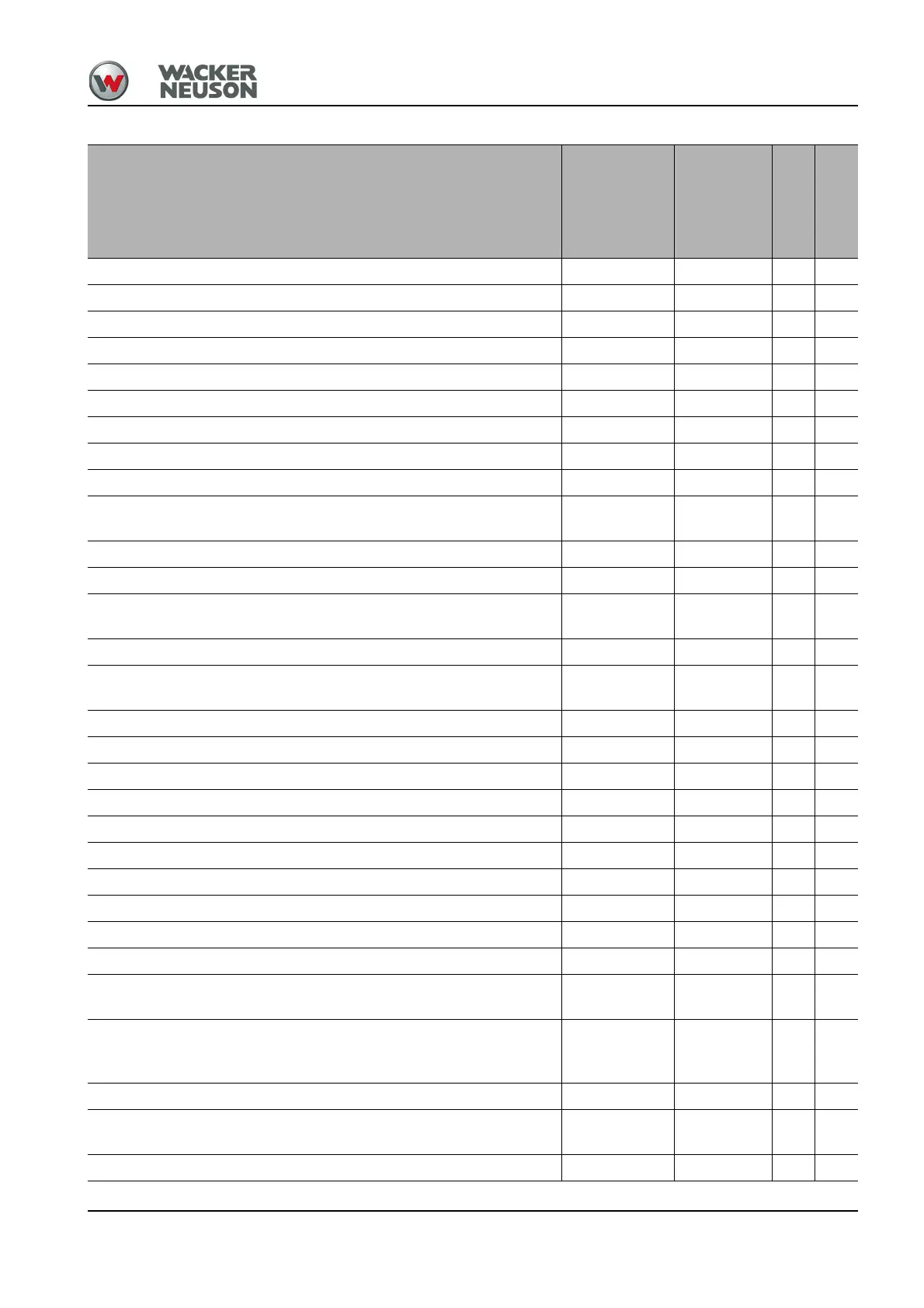

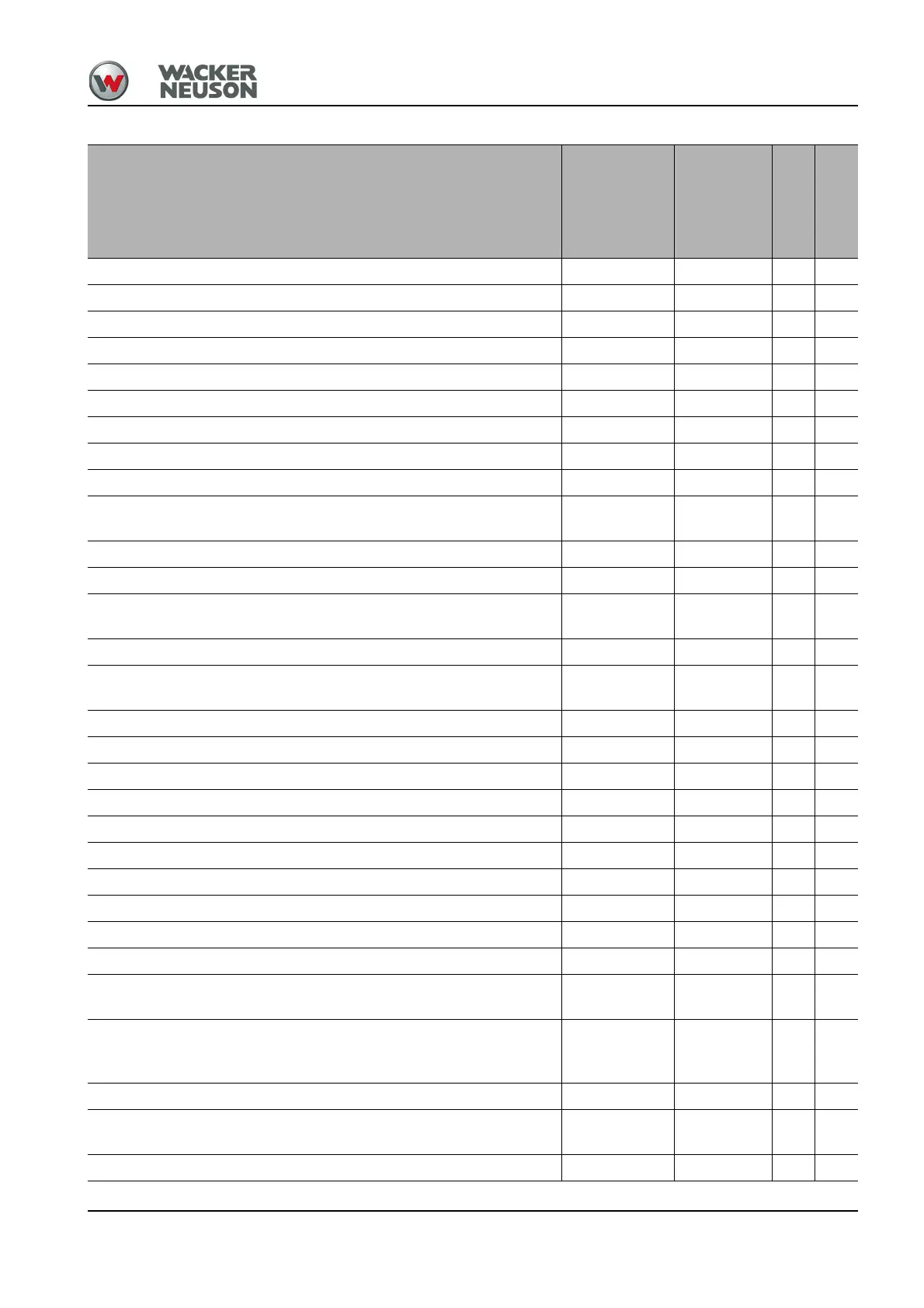

SHB WL34 * 2.0 1-11

Maintenance 1

Maintenance overview

Work to be performed

Operating hours:

250, 750, 1000,

1250, 1750, 2000,

2250, 2750, 3000,

etc.

Operating

hours: 1500,

2500, 3500,

4500, etc.

Once a month

Once a year

Check the gearbox, engine and hydraulic system for leaks • • • •

Check the hydraulic and water radiators for dirt • • • •

Check the coolant and antifreeze levels • • • •

Check the tension and condition of the V-belt • • • •

Check the routing of the hoses and pipes • •

Check the piston rods of the hydraulic cylinders • •

Check the air filter hose • • • •

Examine the intake muffler for damage or exceptional wear •

Check the routing of Bowden cables and electric cables • •

Re-tighten all screws; pay particular attention to the engine mount-

ings, axle mountings and cardan shaft

••

Check the battery acid level • • • •

Clean the battery terminals and check the acid density • •

Check the instruments, indicator lights and acoustic warning

devices

••••

Check the electrical system • • • •

Check the service brake and parking brake, adjust them if neces-

sary

••••

Check the hydraulic steering • • • •

Check the light system (if equipped) • • • •

Check the exhaust system • •

Check the pivot pins and joint bushes • •

Check the center pivot bolts and bearings • •

Check the pressure limiting valves of the hydraulic system • •

Check the idling speed • • • •

Check the speed under load and without load • •

Check the starter and alternator (see engine manual) • •

Check the glow plugs and injection nozzles (see engine manual) • •

Check valve clearance and adjust as necessary (see the engine

manual)

•

If the machine is equipped with a Deutz engine: Check the toothed

belt for the engine control and, if installed, for the auxiliary drive (do

not re-tension, replace every 5 years or after 4500 operating hours)

Check the injectors (every 3000 operating hours)

Check the engine cover lock for correct function, adjust it if neces-

sary

••••

Check the protective ROPS/FOPS structure • •

Loading...

Loading...