3 Prepare the e2695 Separations Module for Operation

110 July 29, 2013, 715003794 Rev. B

The following table lists some needle-wash solvents recommended for use with

certain mobile phase conditions. High sample concentrations can require

other needle-wash solvents.

To prime the needle-wash pump:

1. Be sure the needle-wash tubing is properly installed (see “Install

needle-wash and plunger seal-wash reservoirs” on page 61).

2. Press the Diag screen key in the Main screen.

3. In the Diagnostics screen, press the Prime NdlWash screen key.

Tip: The 30-second needle-wash procedure begins. If solvent does not

flow out the waste tube within 30 seconds, press the Start Again screen

key.

Adjust the seal pack

Adjust the seal pack on these occasions:

• You start up the separations module for the first time. (The separations

module does not perform injections or compression checks until the seal

pack has been adjusted.)

Caution: Use separate solutions and containers for needle wash and

plunger seal wash. The solutions’ functions differ, so using one solution

for both functions can compromise the effectiveness of needle or

plunger-seal washing.

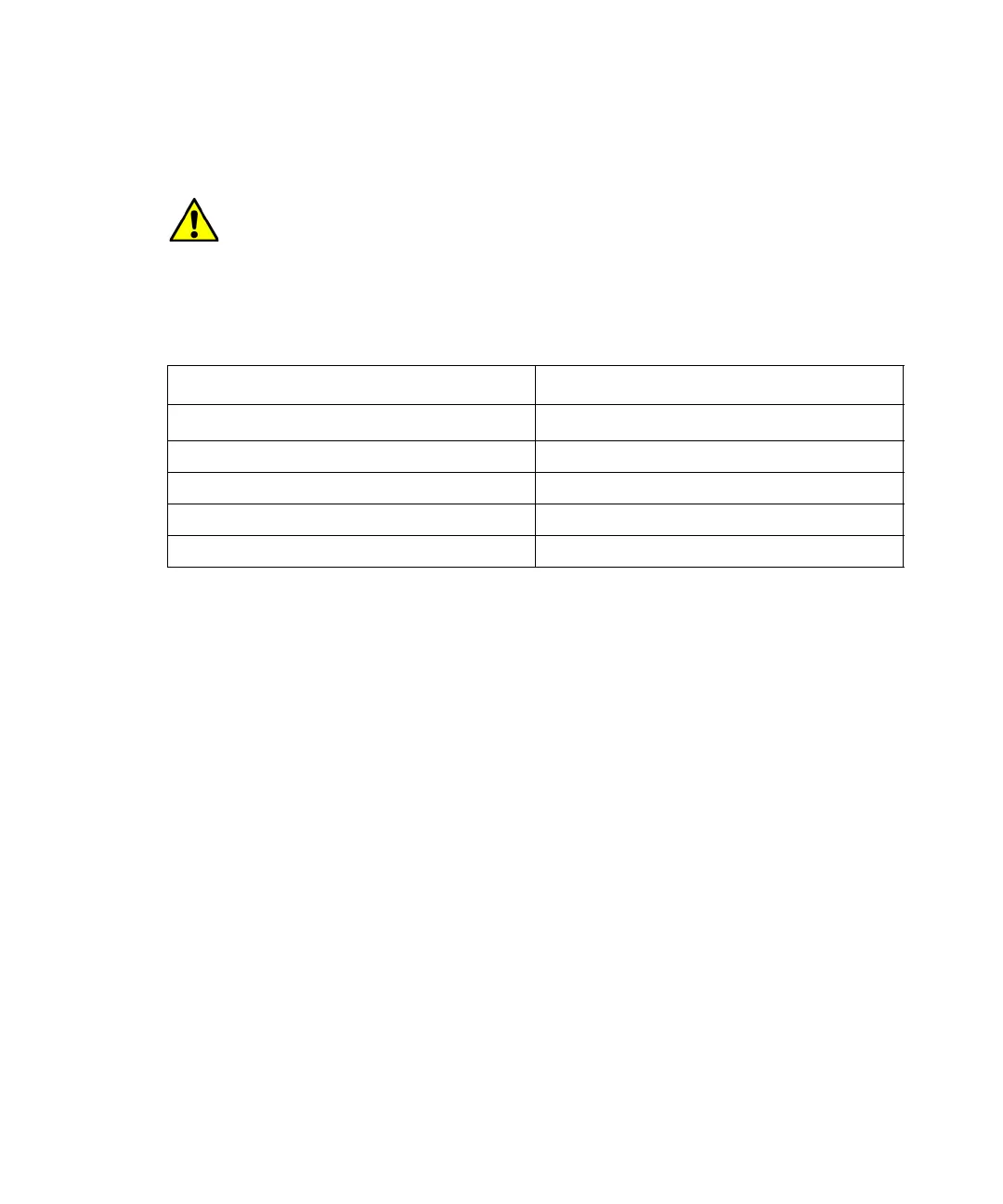

Suggested needle-wash solvents:

Chromatographic condition Needle-wash solvent

Buffered aqueous, reversed-phase

80% organic/20% aqueous

1

1. If the aqueous portion of the analytical solution is pH-adjusted to ensure sample solubility,

match the pH of the aqueous portion of the needle-wash solution to it. If acids are used, avoid

long term exposure of the needle-wash system to halide-containing acids.

Nonaqueous, reversed-phase 100% methanol

Normal phase Mobile phase

GPC Mobile phase

Ion exchange Water

Loading...

Loading...