Solvent management system overview

July 29, 2013, 715003794 Rev. B 29

• Plunger seal wash solvent flows from a reservoir to the solenoid wash

pump and then to a cavity behind the main plunger seal in the primary

head.

• The solvent flows from the head and into the cavity behind the plunger

seal, in the accumulator head.

• From the accumulator head, the solvent flows to waste.

When the solvent management system is delivering solvent, the plunger seal

wash pump intermittently circulates the wash solvent according to a time that

you specify.

Loss of prime protection

When a loss of prime occurs because a solvent reservoir empties, the resultant

loss of operating pressure to below 172 kPa (1.7 bar, 25 psi) for 50 cycles of the

solvent delivery mechanism causes the separations module to stop operating.

Preferred plunger stroke volume

The separations module’s discrete, programmable stroke volumes provide

optimal flow delivery and solvent blending. Nevertheless, you can improve

performance for specific applications by overriding the default

(preprogrammed) stroke volume of 130 µL. To do so, you select a preferred

stroke volume of 25 µL, 50 µL, or 100 µL, as shown in the following table. A

larger stroke volume can be more effective with solvents that require

additional mixing, like trifluoroacetic acid [TFA] gradients. This additional

mixing, unlike static or dynamic mixing, occurs without added delay volume.

In-line vacuum degasser

The design of the PerformancePlus in-line vacuum degasser combines a

variable speed, continuously operating vacuum pump with

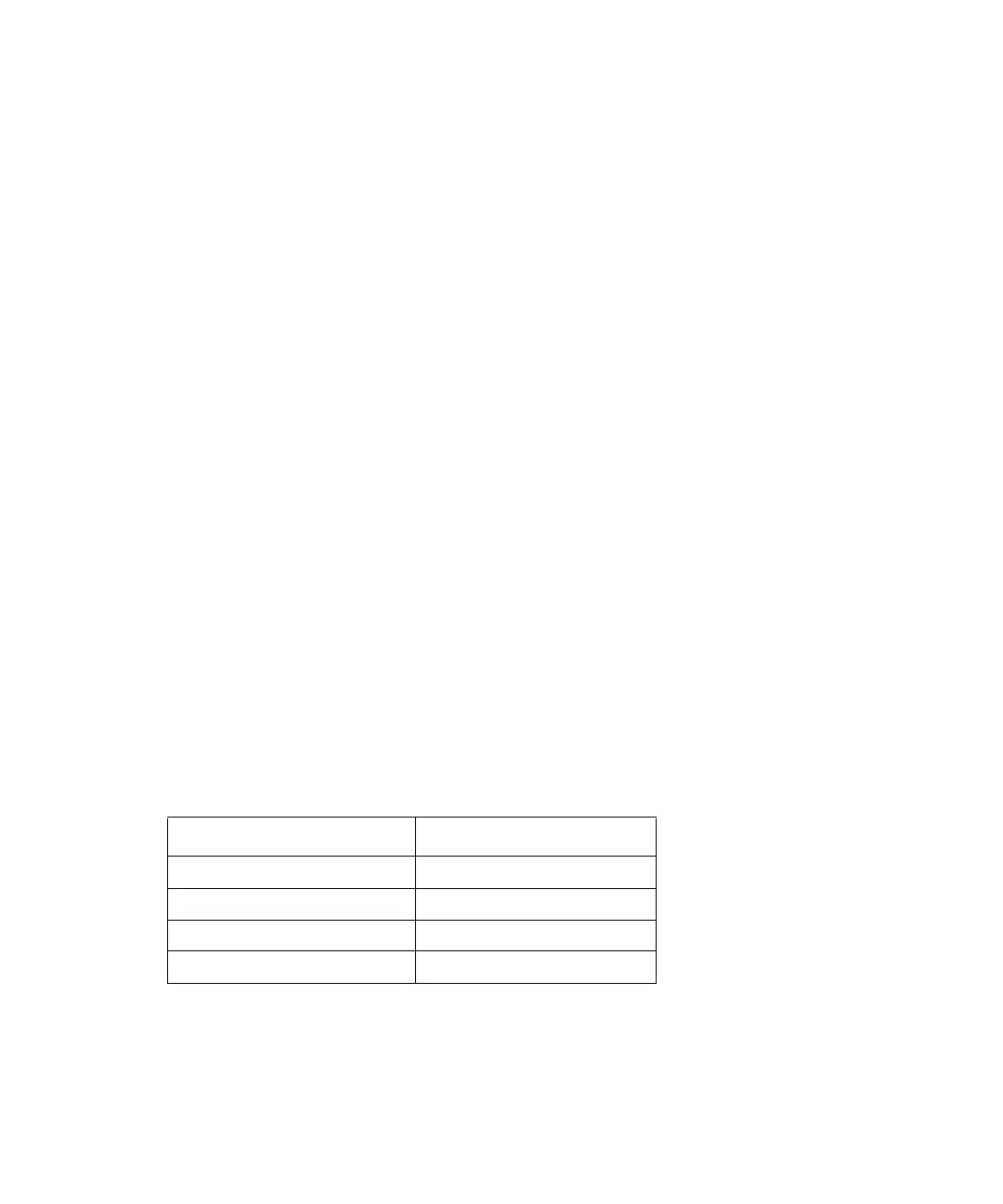

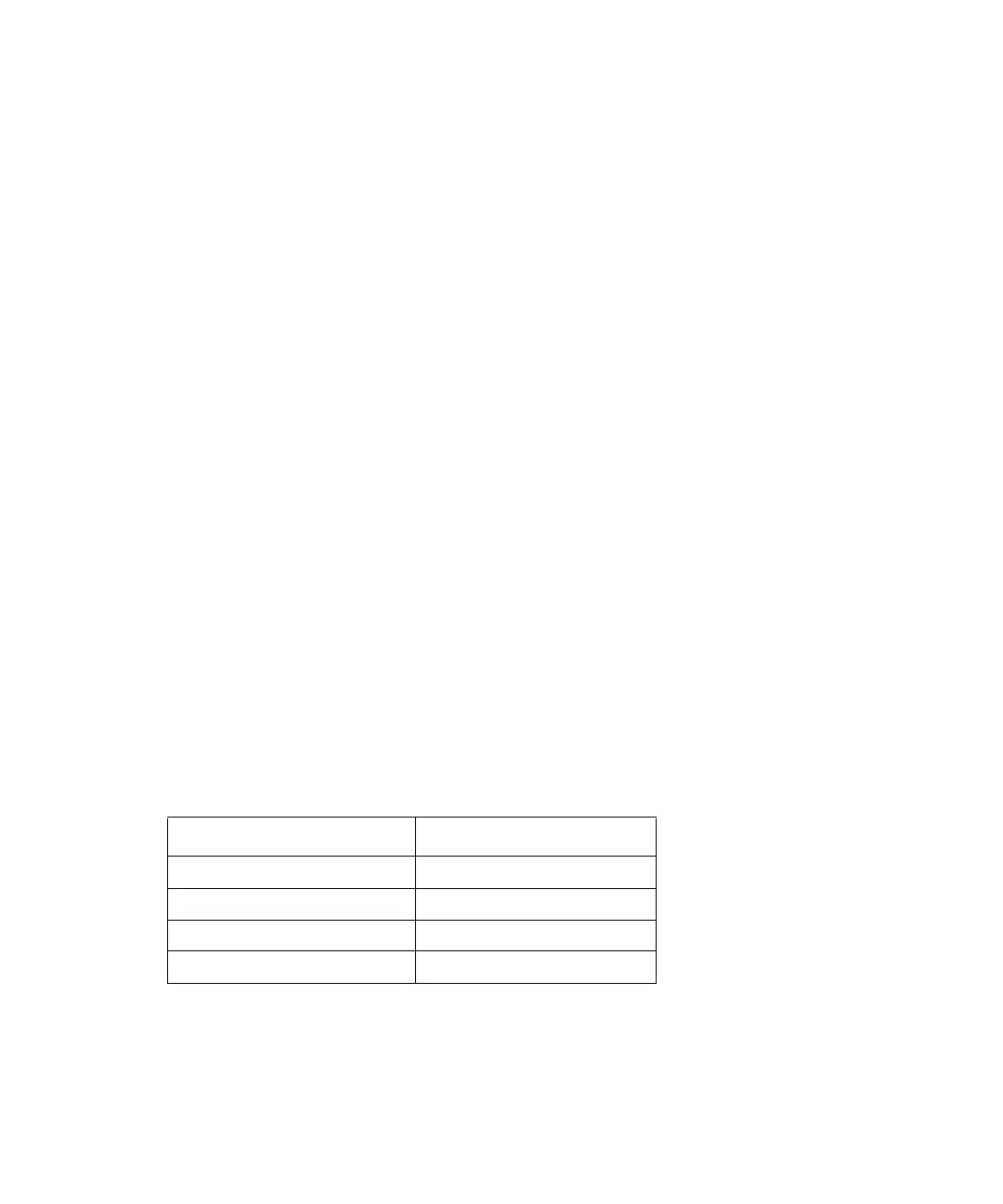

Alternate stroke volumes:

Flow range (mL/min) Stroke volume (µL)

0.050 - 0.530 25

0.531 - 1.230 50

1.231 - 3.030 100

3.031 - 5.000 130

Loading...

Loading...