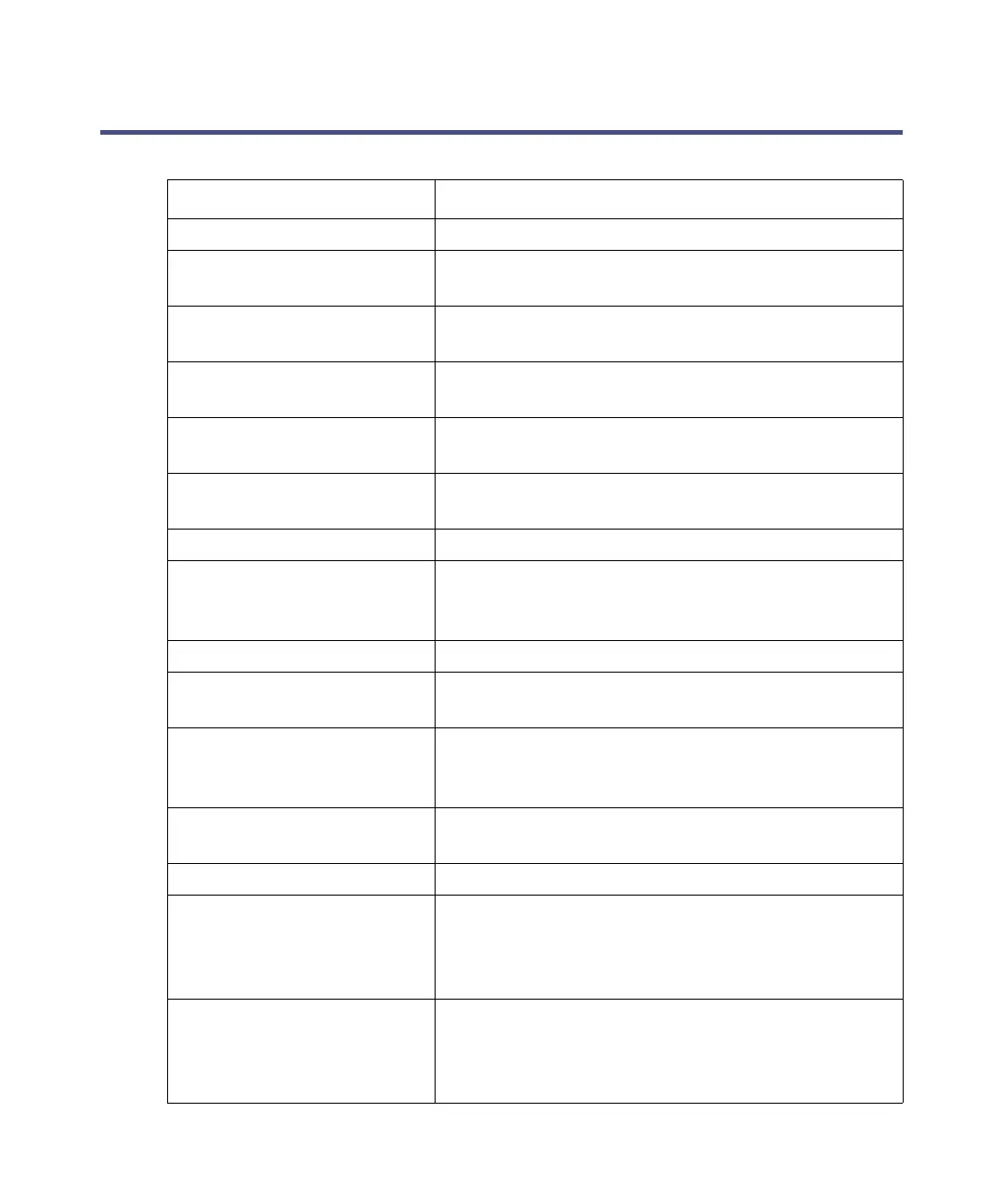

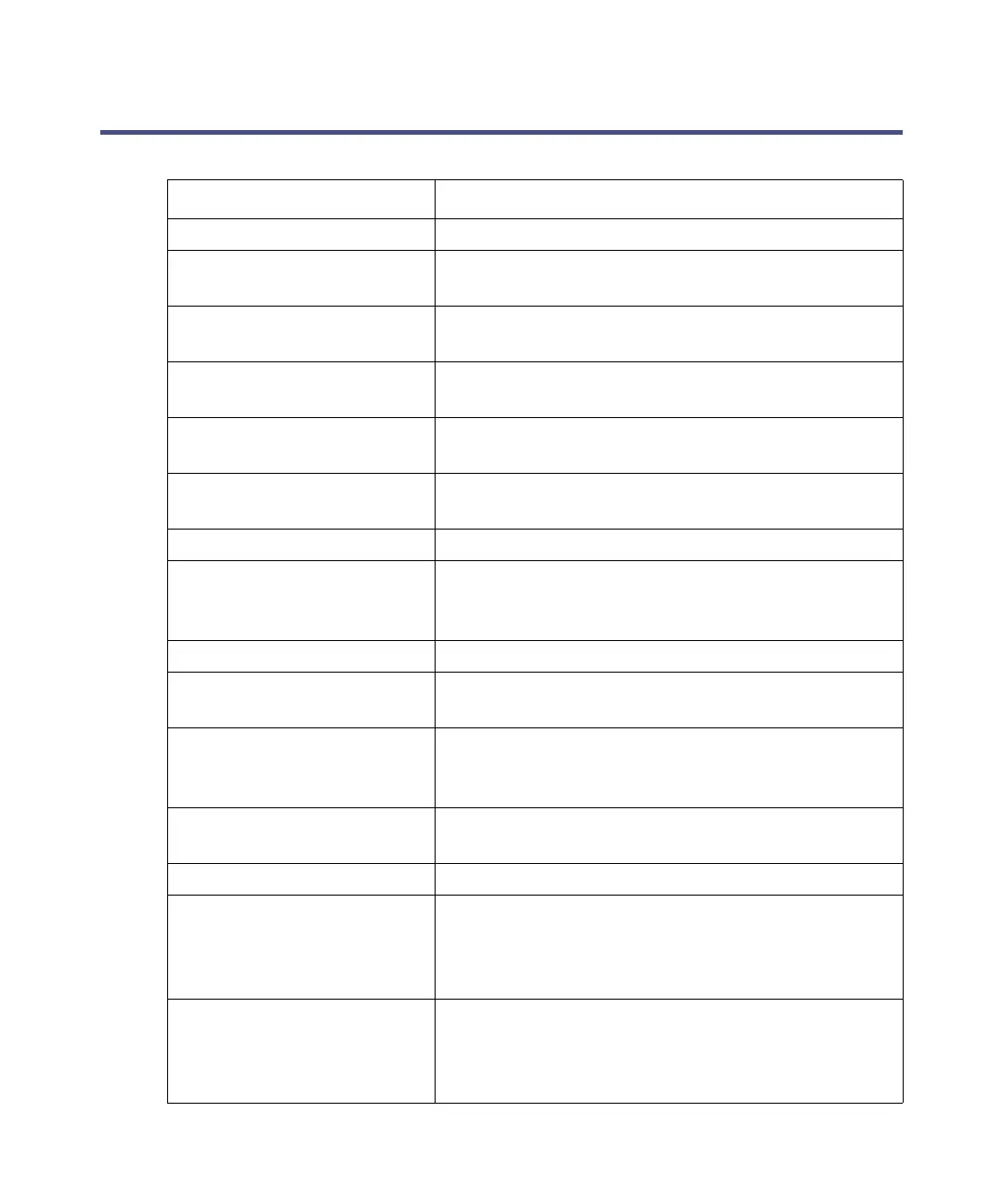

Solvent management specifications

July 29, 2013, 715003794 Rev. B 279

Solvent management specifications

Solvent management system specifications–e2695 XE configuration:

Item Specification

Number of solvents One to four

Solvent conditioning Vacuum degas, four (4) chambers, ≈< 500 uL

internal volume per chamber

Programmable flow rate

range

0.000 and 0.010 to 10.000 mL/min in 0.001

mL/min. increments

Typical operating flow

rate range

0.050 to 5.000 mL/min in 0.001 mL/min

increments

Compressibility

compensation

Automatic and continuous

Effective system delay

volume

< 650 µL, independent of backpressure @ 1

mL/min

Plunger seal wash Integral, active, programmable

Gradient profiles Eleven (11) gradient curves [including linear,

step (2 curves), concave (4 curves), and convex

(4 curves)]

Dry prime/wet prime Automatic, front panel control

Flow ramping Time (0.01 to 30.00 min in 0.01 min increments)

to reach maximum flow rate

Maximum operating

pressure

345 bar (5000 psi) (0.010 to 3.000 mL/min)

Programmable upper and lower limits. Pressure

fall-off at > 3.000 mL/min.

Pressure ripple ≤ 2.5% (1 mL/min, degassed methanol, at 1700

psi backpressure)

Composition range 0.0 – 100.0 in 0.1% increments

Composition accuracy ±0.5% absolute, independent of backpressure

(Proportioning valve pair test [degassed

methanol (or methanol/propylparaben), 2

mL/min, 254 nm])

Composition precision ≤ 0.15% RSD or ≤ 0.02 min SD, whichever is

greater, based on retention time. (Degassed

methanol/water 60:40 Dial-a-Mix, 1 mL/min, six

replicates, phenone mix, 254 nm.)

Loading...

Loading...