6.7 Torque Control

6.7.2 Adjusting the Torque Reference Offset

6-43

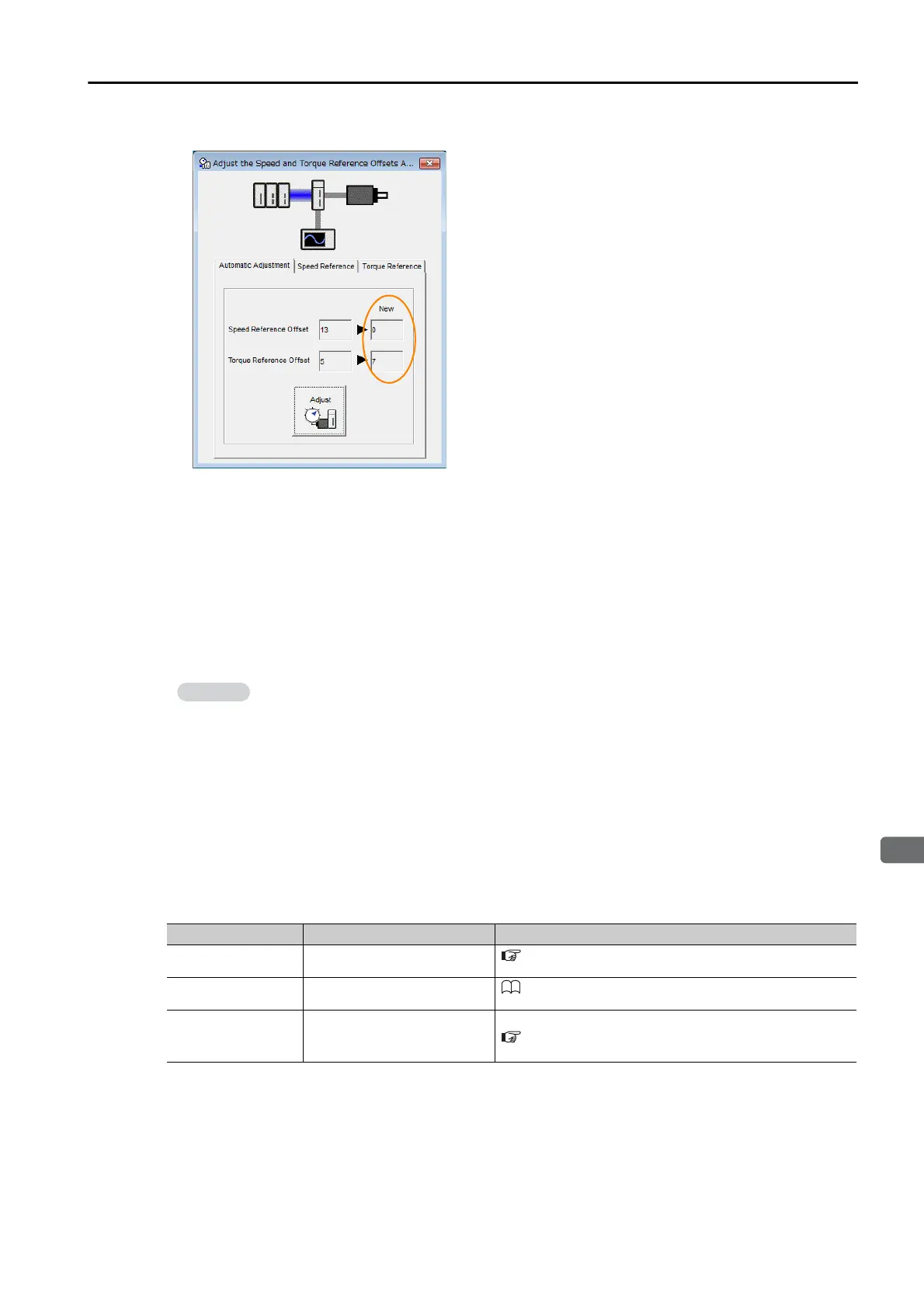

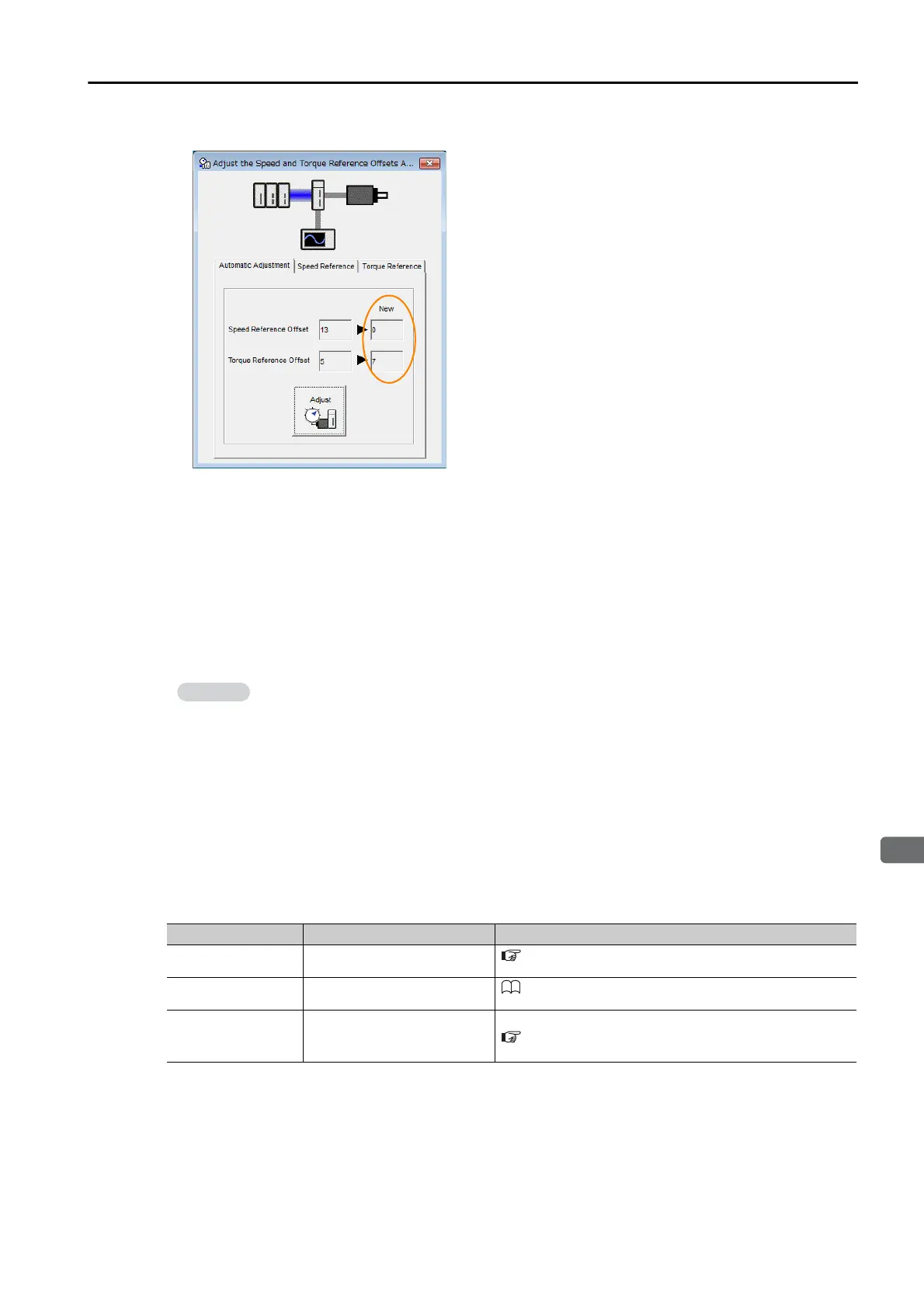

The value that results from automatic adjustment will be displayed in the New Box.

Note: You cannot automatically adjust the reference offset if a position loop is created with the host controller. Man-

ually adjust the torque reference offset.

This concludes the procedure to automatically adjust the torque reference offset.

Manually Adjusting the Torque Reference Offset

You can directly input a torque reference offset to adjust the torque reference. The offset is

adjusted manually in the following cases.

• To intentionally set the offset to a desired value

• To check an offset that was set automatically

Preparations

The following conditions must be met to manually adjust the reference offset.

• The parameters must not be write prohibited.

• The servo must be in ready status.

Applicable Tools

The following table lists the tools that you can use to manually adjust the torque reference off-

set and the applicable tool functions.

The offset does not use a parameter, so it will not change even if the parameter settings are

initialized.

Tool Function Operating Procedure Reference

Panel Operator Fn009

13.4.10 Manually Adjust Torque Reference Offset

(Fn00B) on page 13-19

Digital Operator Fn009

Σ-7-Series Digital Operator Operating Manual (Manual

No.: SIEP S800001 33)

SigmaWin+

Setup

−

Speed/Torque

Reference Offset Adjust-

ment

Operating Procedure on page 6-44

Loading...

Loading...