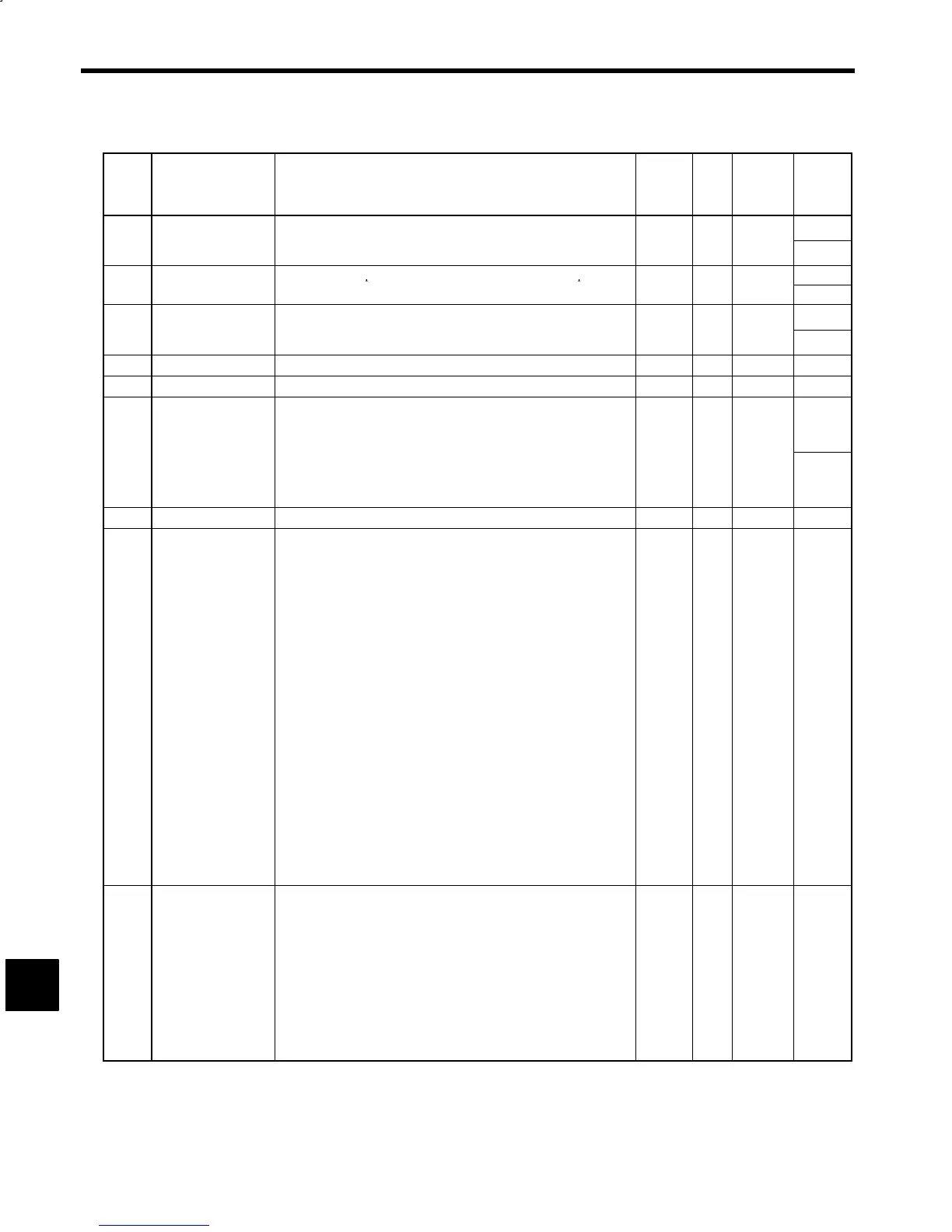

Control Constants

10 -12

Table 10.3 Magnetic Sensor Orientation Constants (continued)

Con-

stant

No.

Name Explanation Change

*

1

Unit Standard

Setting

Upper

Limit/

Lower

Limit

Starting Soft Start

Soft start time for accelerating from stop to orientation speed. Use this

50

C3-15

me

T

SFO

parame

er

ore

uce gear no

se a

s

ar

ng.

Acceleration rate is (500 min

−1

)/sec.

No ms 0

0

Flux Level Flux level at completion of orientation. Motor noise and torque

100

C3-16

φ

ORT

change in proportion to flux level.

No --- 60

15

Orientation Speed

Reduction coefficient to set orientation speed in proportion to the

32767

C3-17

e

uc

on

oe

c

en

K

SOR

rave

ng ang

e

or

ncremen

a

pos

on

ng.

No --- 0

0

C3-18

--- ---

--- --- --- ---

C3-19

--- ---

--- --- --- ---

Sensor Signal Stan-

dardization Angle

θ

SEN

Angle for standardizing magnetic sensor signal detection sensitivity

θ

SEN

= 180°× Detection range (mm (inches)) ÷ Mounting radius ÷ π

Set 20.0 to θ

SEN when

θ

SEN

> 20.0.

20.0

C3-20

For detection range, check the specifications of the magnetizer and

apply the values below:

MG-1378BS (15 mm (0.59 inches))

MG-1444S (7 mm (0.28 inches))

No Deg. 5.0

5.0

C3-21

--- ---

--- --- --- ---

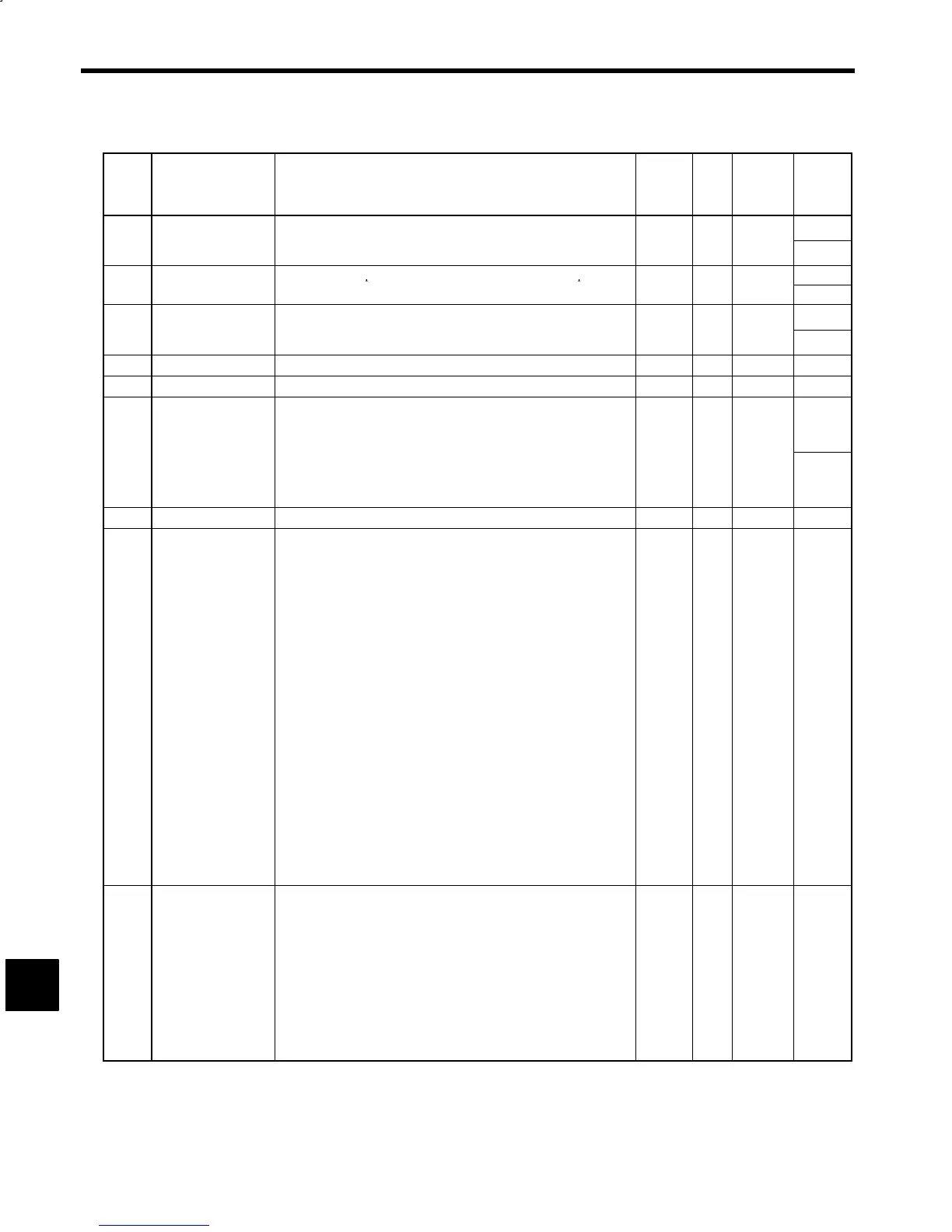

Orientation Control

Signal Selections 1

SEL-M1

*2

Control mode setting signals, e.g., for specifying the direction of

rotation in orientation control.

S Bits 1 and 0: Positioning rotation direction

00: Automatically selected rotation direction

01: Same direction as the forward/reverse run signal

10: Fixed rotation direction

11: Automatically selected rotation direction

S Bit 2: Selection for fixed rotation direction

0: Forward rotation of load shaft

1: Reverse rotation of load shaft

S Bit 3: Stop position reference code

0: 12-bit binary

C3-22

1: 3-digit BCD

S Bit 4: Tuneup operation

0: Tuneup enabled

1: Tuneup disabled

S Bit 5: Incremental positioning reference point

0: Previous stop reference position

1: Current stop position

S Bit 6: Encoder selection

0: Load shaft encoder

1: Motor encoder

S Bit 7: Rotation direction of motor and load shaft

0: Reverse

1: The same

No --- 11000000 ---

Orientation Control

Signal Selections 2

SEL-M2

*2

Dither signal pattern and gain

S Bit 1: Dither signal pattern

0: 6 steps (83 Hz)

1: 2 steps (250 Hz)

S Bits 4, 3, and 2: Dither signal level (H) (i.e., MGR and LGR are OFF)

000: 0.0% 011: 7.5% 110: 15.0%

C3-23

.

.

.

001: 2.5% 100: 10.0% 111: 17.5%

010: 5.0% 101: 12.5%

S Bit 7, 6, and 5: Dither signal level (L) (i.e., MGR or LGR is ON)

000: 0% 011: 3% 110: 6%

001: 1% 100: 4% 111: 7%

010: 2% 101: 5%

No --- 00000000 ---

10

Loading...

Loading...