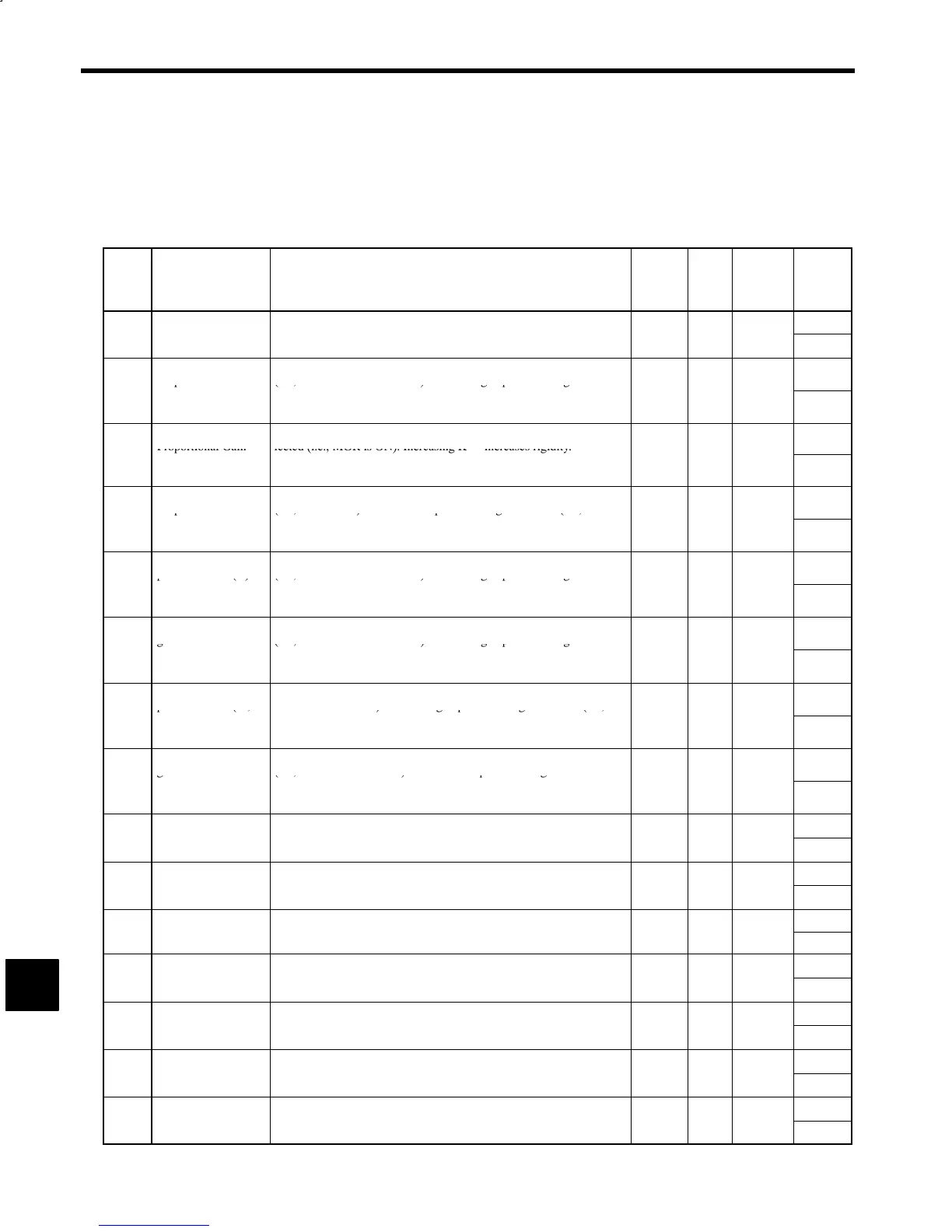

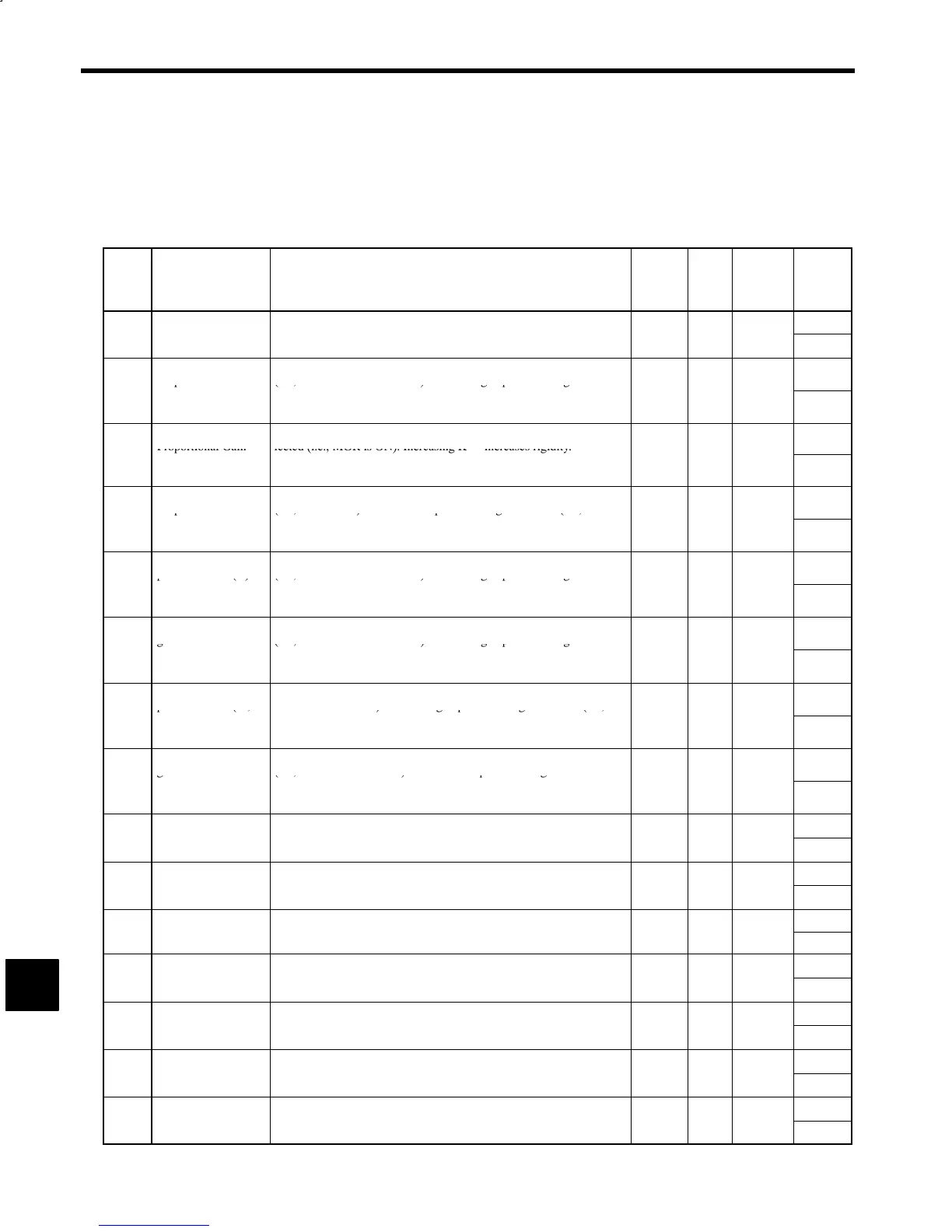

Control Constants

10-8

10.2 Encoder Orientation Constants

The encoder orientation constants are listed in the following table.

Table 10.2 Encoder Orientation Constants

Con-

stant

No.

Name Explanation Change

*

1

Unit Standard

Setting

Upper

Limit/

Lower

Limit

Load Shaft Position-

Mechanical origin of the load shaft. Set difference from encoder ori-

4095

C2-01

ng Or

g

n

P

ORG

g

ns

gna

p

ase C

pu

ses.

Yes Pulse 0

0

Position Control

Proportional Gain

Position control proportional gain when high-speed gear is selected

(i.e., MGR and LGR are OFF) or when high-speed winding is se-

99

C2-02

(H)

K

PH

lected (i.e., CHW is OFF). Increasing K

PH

increases rigidity.

Speed reference (pps) = K

PH

× Position tolerance (pulses)

Yes 1/s 15

1

Position Control

Proportional Gain

Position control proportional gain when medium-speed gear is se-

lected (i.e., MGR is ON). Increasing K

PM

increases rigidity.

99

C2-03

(M)

K

PM

Speed reference (pps) = K

PM

× Position tolerance (pulses)

Yes 1/s 15

1

Position Control

Proportional Gain

Position control proportional gain when low-speed gear is selected

(i.e., LGR is ON) or when low-speed winding is selected (i.e., CHW

99

C2-04

(L)

K

PL

is ON). Increasing K

PL

increases rigidity.

Speed reference (pps) = K

PL

× Position tolerance (pulses)

Yes 1/s 15

1

Speed Control Pro-

portional Gain (H)

Speed control proportional gain when high-speed gear is selected

(i.e., MGR and LGR are OFF) or when high-speed winding is se-

255

C2-05

K

VHO

lected (i.e., CHW is OFF) in orientation control (i.e., ORT is ON).

Torque reference P = K

VHO

× Speed tolerance

Yes %/Hz 40

1

Speed Control Inte-

gral Time Constant

Speed control integral time constant when high-speed gear is selected

(i.e., MGR and LGR are OFF) or when high-speed winding is se-

1000

C2-06

(H)

τ

VHO

lected (i.e., CHW is OFF) in orientation control (i.e., ORT is ON).

Torque reference I = Torque reference P × Time/τ

VHO

Yes ms 100

5

Speed Control Pro-

portional Gain (M,

Speed control proportional gain when low-speed gear is selected (i.e.,

MGR or LGR is ON) or when high-speed winding is selected (i.e.,

255

C2-07

L)

K

VLO

CHW is ON) in orientation control (i.e., ORT is ON).

Torque reference P = K

VLO

× Speed tolerance

Yes %/Hz 40

1

Speed Control Inte-

gral Time Constant

Speed control integral time constant when low-speed gear is selected

(i.e., MGR or LGR is ON) or when low-speed winding is selected

1000

C2-08

(M, L)

τ

VLO

(i.e., CHW is ON) in orientation control (i.e., ORT is ON).

Torque reference I = Torque reference P × Time/τ

VLO

Yes ms 100

5

Positioning Comple-

Detection width for outputting completion signal when the load shaft

200

C2-09

t

on Detect

on W

t

Z

FIN

approac

es t

e stop reference pos

t

on. Detect

on w

t

s stop refer-

ence position ±Z

FIN.

No Pulse 5

0

Positioning Comple-

Set value for canceling completion signal when the load shaft is

200

C2-10

t

on Cance

W

t

Z

CAN

move

after comp

et

on s

gna

s output. Cance

w

t

s stop refer-

ence position ±Z

CAN.

No Pulse 10

Z

FIN

Orientation Speed

Speed applied (after detecting encoder origin) until changing to the

−

600

C2-11

S

ORT

servo loop during orientation.

No min

−

400

40

BCD Stop Position

Angle set value per minimum increment of stop position BCD com-

180.0

C2-12

Reference Reso

u-

tion P

BCD

man

.

No Deg. 1.0

0.5

Virtual Stop

Stop position offset for smoothing stop operation when the servo loop

100

C2-13

Pos

t

on Offset

P

IMG

s use

.W

en Z

FIN

s reac

e

, offset

ecomes 0.

No Pulse 0

0

Orientation Speed

Speed changing ratio for gradually reducing orientation speed to

100

C2-14

C

ang

ng Rat

o

R

SOR

re

uce gear no

se w

en sw

tc

ng from or

entat

on spee

to servo

loop speed.

No --- 0

0

Starting Soft Start

Soft start time for accelerating from at rest state to orientation speed.

50

C2-15

T

me

T

SFO

Use t

s parameter to re

uce gear no

se at start

ng. Acce

erat

on rate

is (500 min

−1

)/sec.

No ms 0

0

10

Loading...

Loading...