13.1 Maintenance and Inspection

13 -3

13.1 Maintenance and Inspection

This section explains the maintenance and inspection methods for the Inverter and Converter.

13.1.1

Daily Inspections

Check the following items while the system is in operation.

D

Are there abnormal motor noises or vibration?

D

Is there any abnormal heat?

D

Is the ambient temperature too high?

D

Is the value displayed on the output voltage monitor higher than normal?

13.1.2 Periodic Inspections

Check the following items during periodic maintenance.

To prevent electric shock, turn OFF the power supply to the main circuit and check that the CHARGE indi-

cator and 7-segment display have gone out before performing maintenance operations.

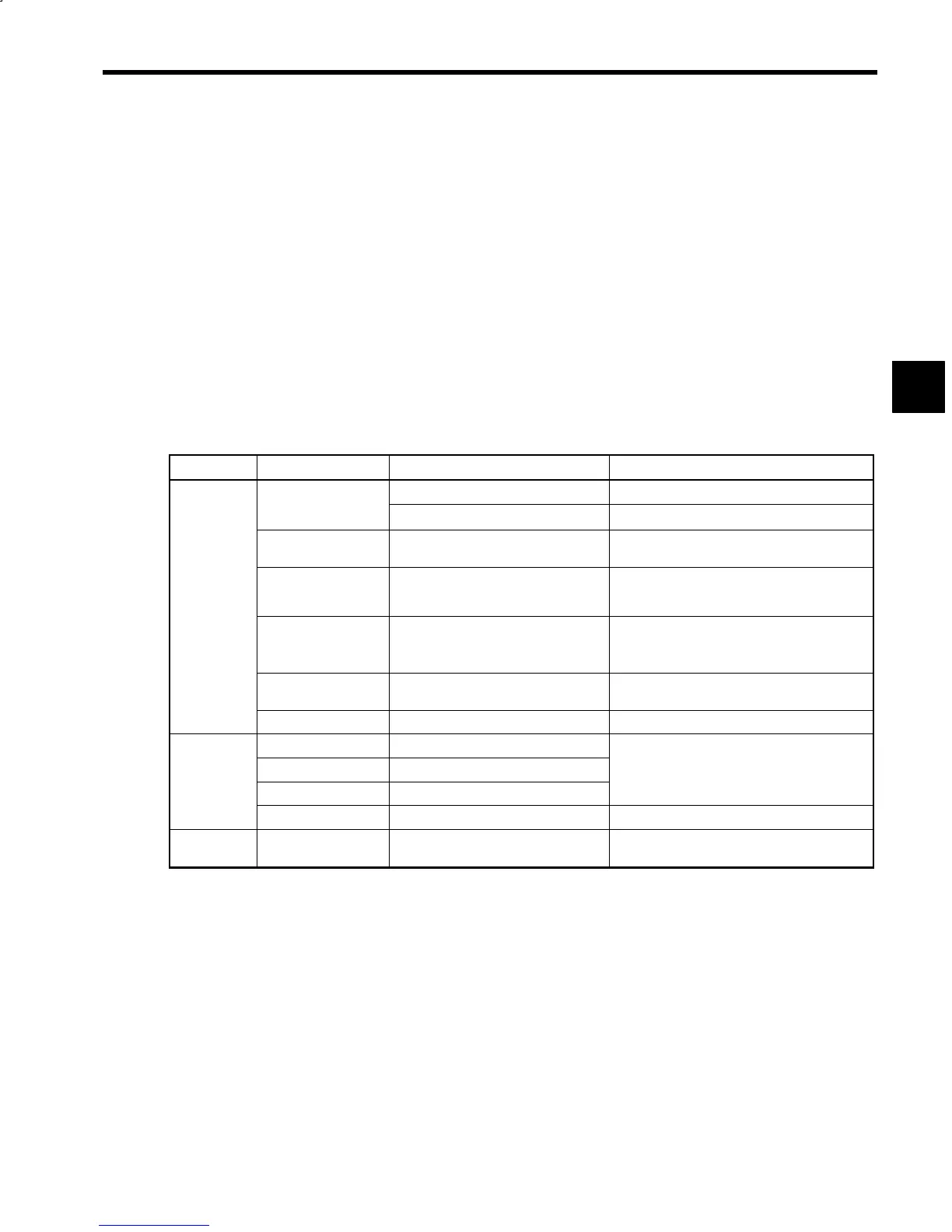

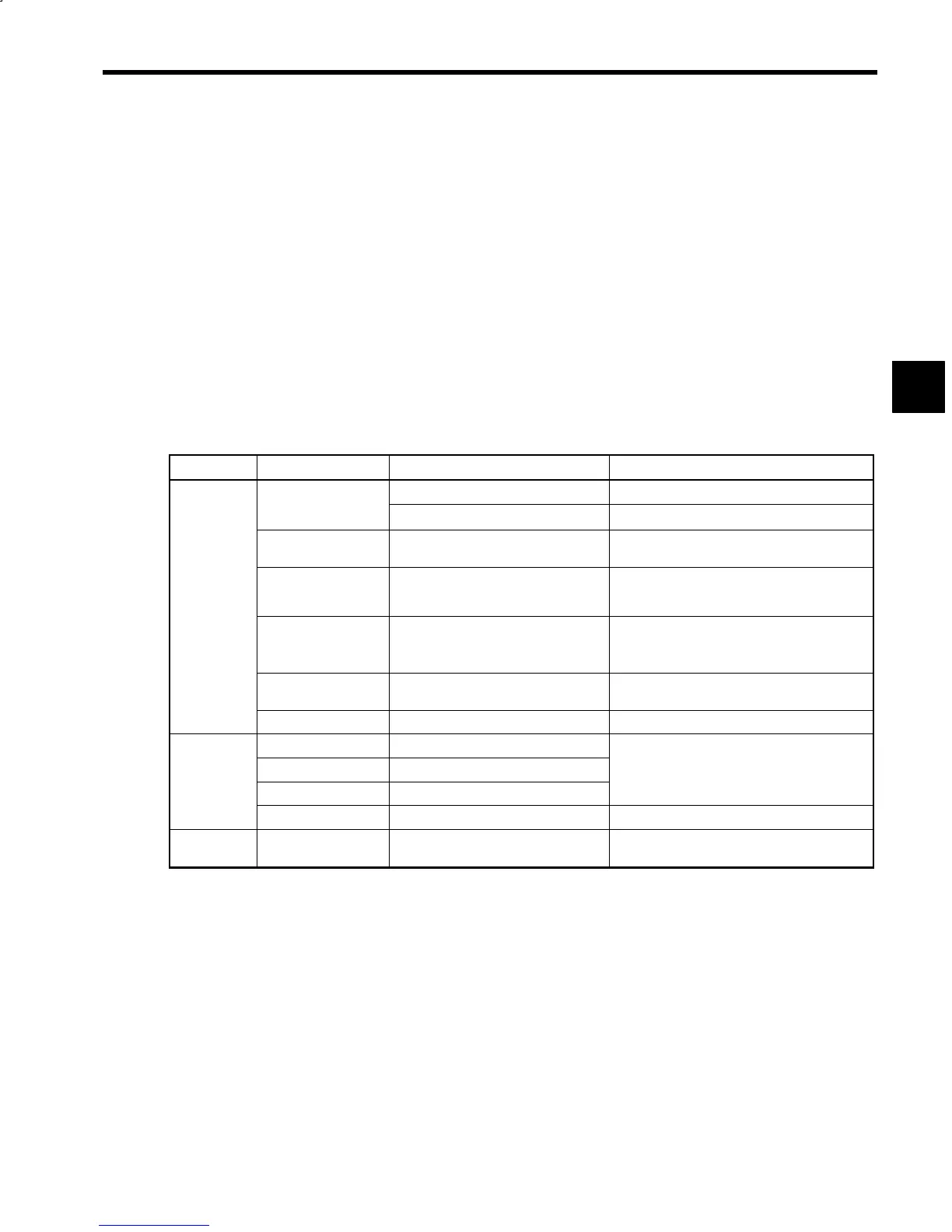

Table 13.1 Periodic Inspection Items

Area Component Check Corrective Action

External terminals, Unit

Loose screws Tighten.

mounting bolts, con-

nectors, etc.

Loose connectors Tighten.

Heatsink Build-up of dust and dirt

Blow with dry compressed air of 39.2¢10

4

to

58.8¢10

4

Pa (4 to 6kg¡cm

2

) pressure.

Inverter and

Converter

Printed circuit boards Accumulation of conductive dust or oil

Blow with dry compressed air of 39.2¢10

4

to

58.8¢10

4

Pa (4 to 6kg¡cm

2

) pressure. If dust and oil

cannot be removed, replace the board.

Cooling fan

S For abnormal noise and vibration

S Whether the cumulative operation time

exceeds 20,000 hours or not.

Replace the cooling fan.

Power elements Accumulation of dust and dirt

Blow with dry compressed air of 39.2¢10

4

to

58.8¢10

4

Pa (4 to 6kg¡cm

2

) pressure.

Smoothing capacitor Discoloration or odor Replace the capacitor or Unit.

Bearing noise Abnormal noise or increase of noise level

Related to

Vibration Abnormal vibration

Replace the bearings.

Bearings

Bearing temperature Abnormal temperature rise

Grease No leakage Remove the cause.

Motor and

Cooling Fan

Operating status Normal operation

Remove the cause of fan halt or replace the fan if a

fault is found.

13

Loading...

Loading...