15.3 Determining Drive Capacity

15 -13

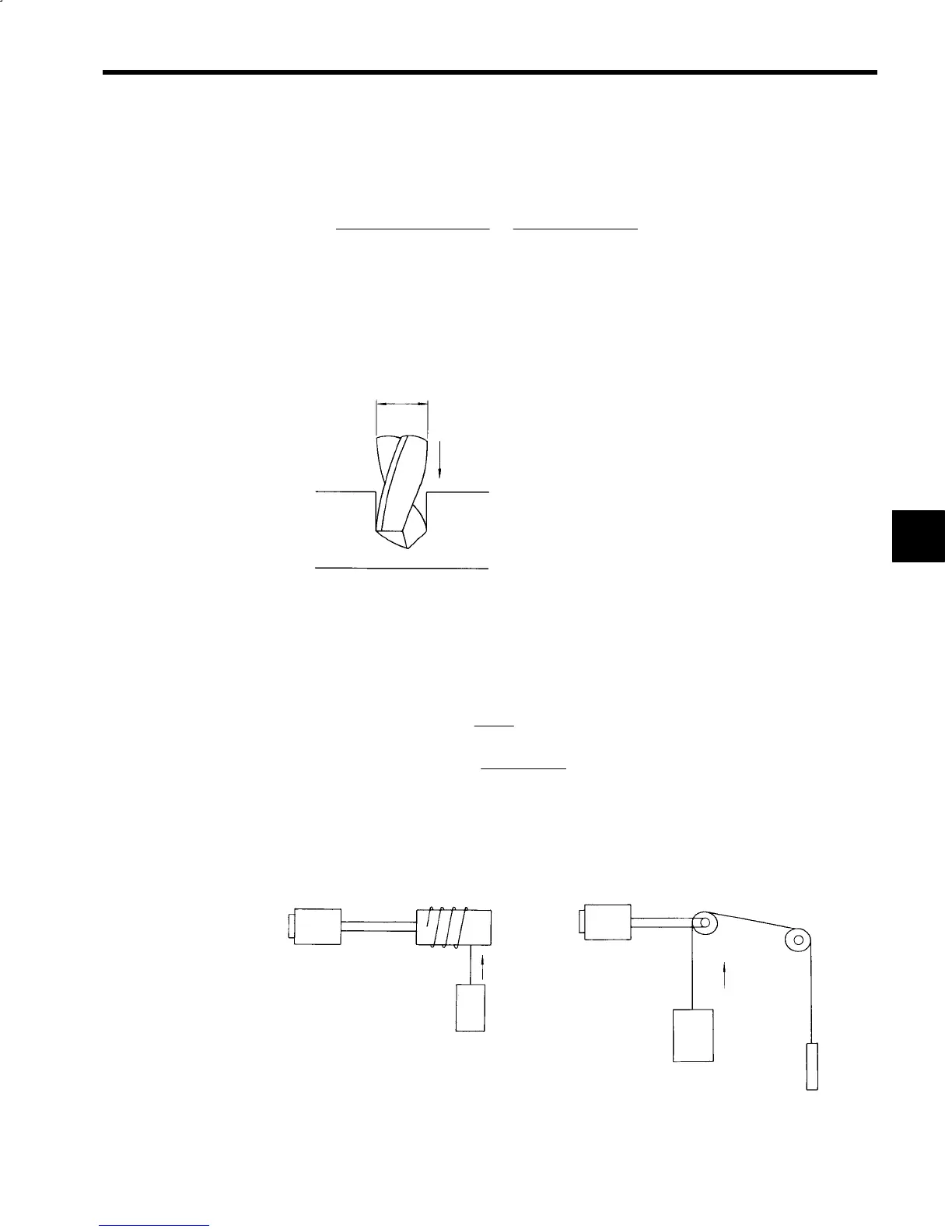

As shown in Fig. 15.16, when performing drill processing, the blade is mounted to the main axis and ro-

tated, opening a hole in the material being processed, so the motive force P

D

required can be expressed

using the following formula. The load torque M differs depending on the material, and the ratio of the drill

radius D: Feed speed f, so care must be applied.

P

D

=

M ⋅ 2πn

60 × 100 × 1000 × η

D

=

πD

2

f

4 × 1000 × S

D

η

D

(kW)

M: Drill load torque (N

⋅

cm)

n: Main axis speed (min

−1

)

η

D

: Machine efficiency 0.7 to 0.85

D: Drill radius (mm)

f: Feed speed (mm/min.)

S

D

: Cutting efficiency (i.e., cutting amount per 1 kW per minute) (CC/kW/min.)

D

f

Fig 15.16 Example of Drill Processing

J

Gravity Load Drive

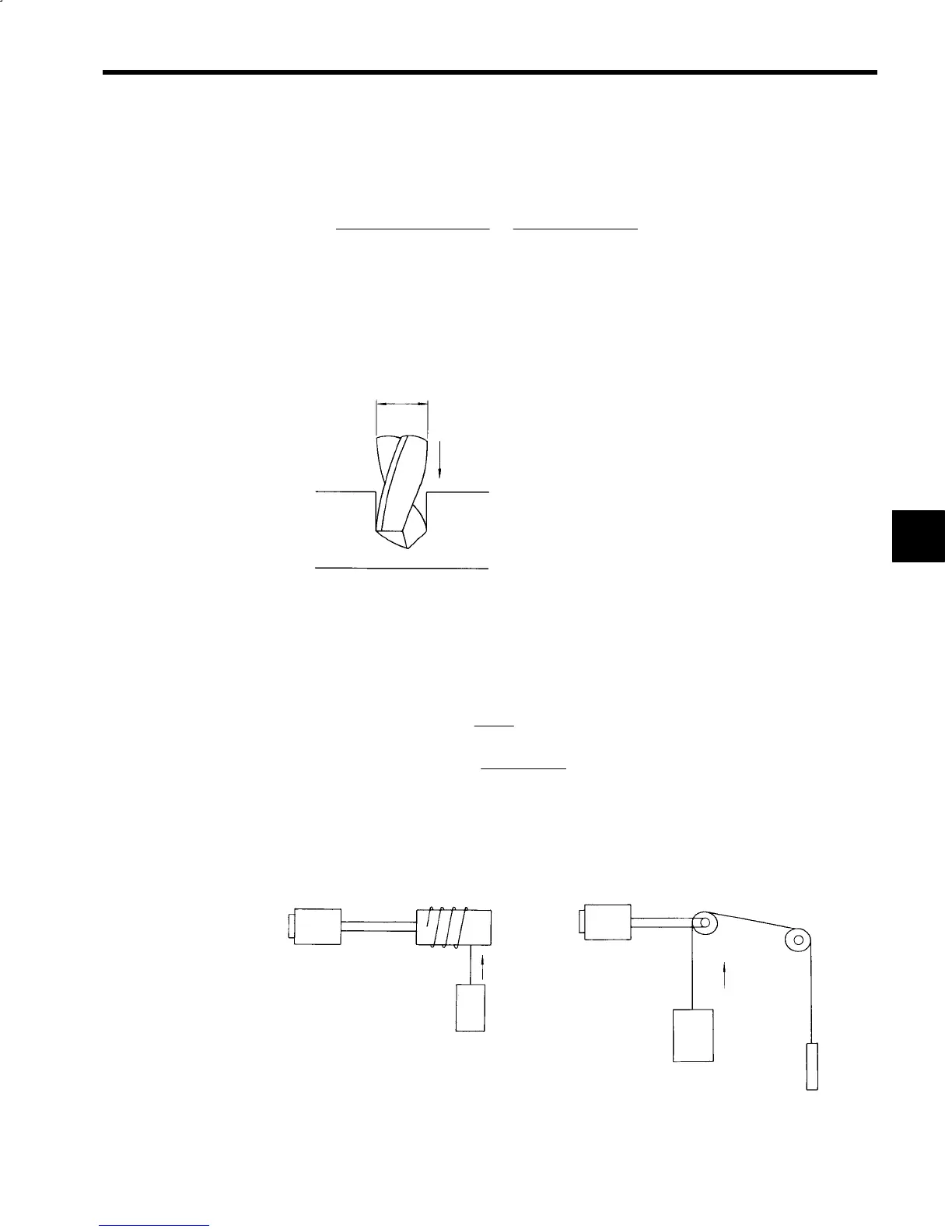

The motive force required to move a load such as a crane or loader vertically differs greatly depending on

whether or not a counterweight is used. The motive force in each case can be expressed using the following

formulas.

Without counterweight

P

GL

=

m

L

V

6120η

(kW)

With counterweight

P

GLC

=

(

m

L

− m

C

)

V

6120η

(kW)

V: Vertical travel speed (m/min.)

η

: Machine efficiency

m

L

: Load mass (kg)

m

C

: Counterweight mass (kg)

Motor

Drum

Speed

V (m/min)

Load

m

L

(kg)

Motor

Speed

V (m/min)

m

L

(kg)

m

C

(a) Without Counterweight (b) With Counterweight

Fig 15.17 Gravity Loads

15

Loading...

Loading...