Maintenance Schedule

AEROSET

®

Customer Training Guide 10-5

94858-103 — July 2003

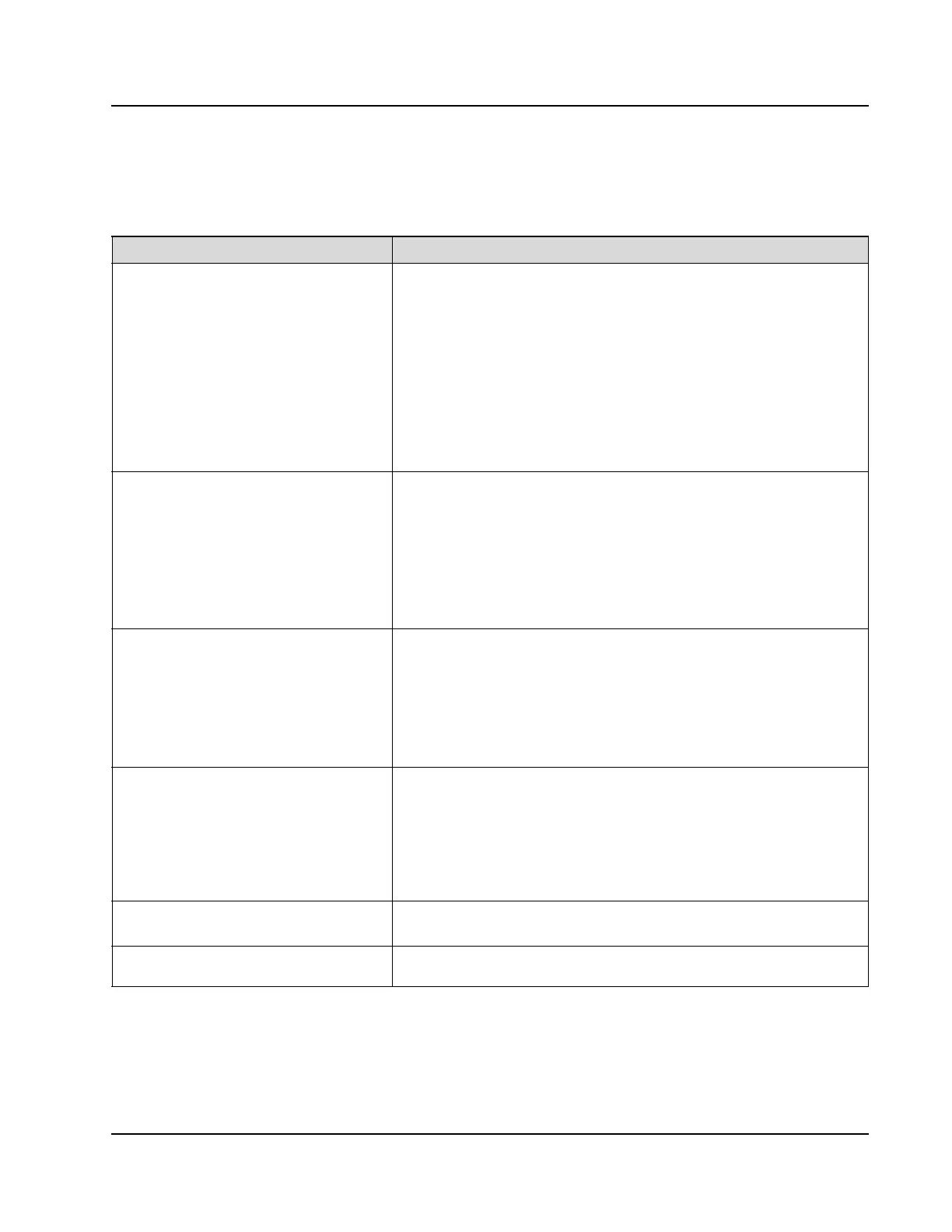

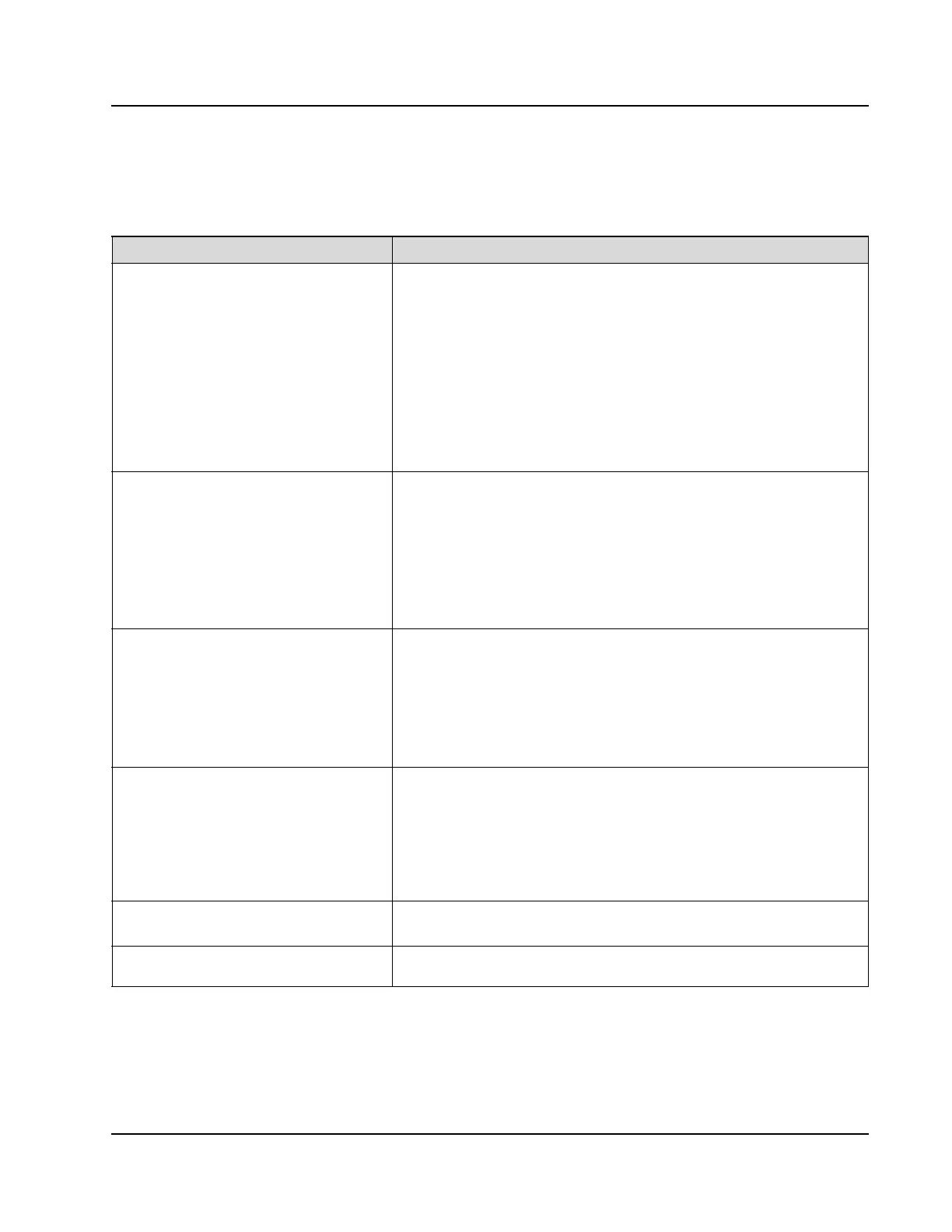

MAINTENANCE SCHEDULE

FREQUENCY PROCEDURE

DAILY CHECKS • Check Reagents/Solutions Inventory

• Perform START UP

• Check 1mL Syringes

• Check Wash Solution Trays

• Check Sample and Reagent Syringes and Solenoid Valves

• Check High-Concentration Waste Container

• Check Refrigerator Condensation Pan

• Check DI Water System

• Perform SHUTDOWN

WEEKLY • Check Sample and Reagent Probes

• Clean Outside of the Sample and Reagent Probes

• Clean Mixers

• Check Tubing from the High-Concentration Waste Drain Hose and

High-Concentration Waste Pump Output T-Fitting

• Clean Touchscreen Display

• Check ICT™ Probe and Tubing

MONTHLY • Check/Clean Reagent Supply Centers

• Clean Carousel Sampler Area and Carousels

• Check Sample and Reagent Dispense Components

• Clean Cuvette Washer Nozzles

• Check Cuvette Washer High-Concentration Waste Nozzle Tubing

• Clean DI Water Filter (if installed)

QUARTERLY • Syringe Seal Tip (1 and 2) and O-ring Replacement (on sample, reagent,

and wash solution syringes)

• Wash Solution Syringe (1mL) Replacement

• ICT Reference Solution (1mL) Replacement

• ICT Aspiration Syringe (1mL) Replacement

• 0.22 Micron Filter Replacement (if applicable)

SEMI-ANNUALLY • Wash Solution Filters Replacement

• ICT Reference Solution Filter Replacement

ANNUALLY • Check Valve Replacement (Wash Solution and Reference Solution

Pumps 1mL Syringes)

Loading...

Loading...