23

SETUP "BASIC SETTINGS"

Par.

7. 4

Conrm access

or data change

Exit the function or

data change

Delete

selected

character

Scroll

(LEFT /

RIGHT)

Data

increase /

decrease

Scroll

(UP /

DOWN)

Enter

selected

character

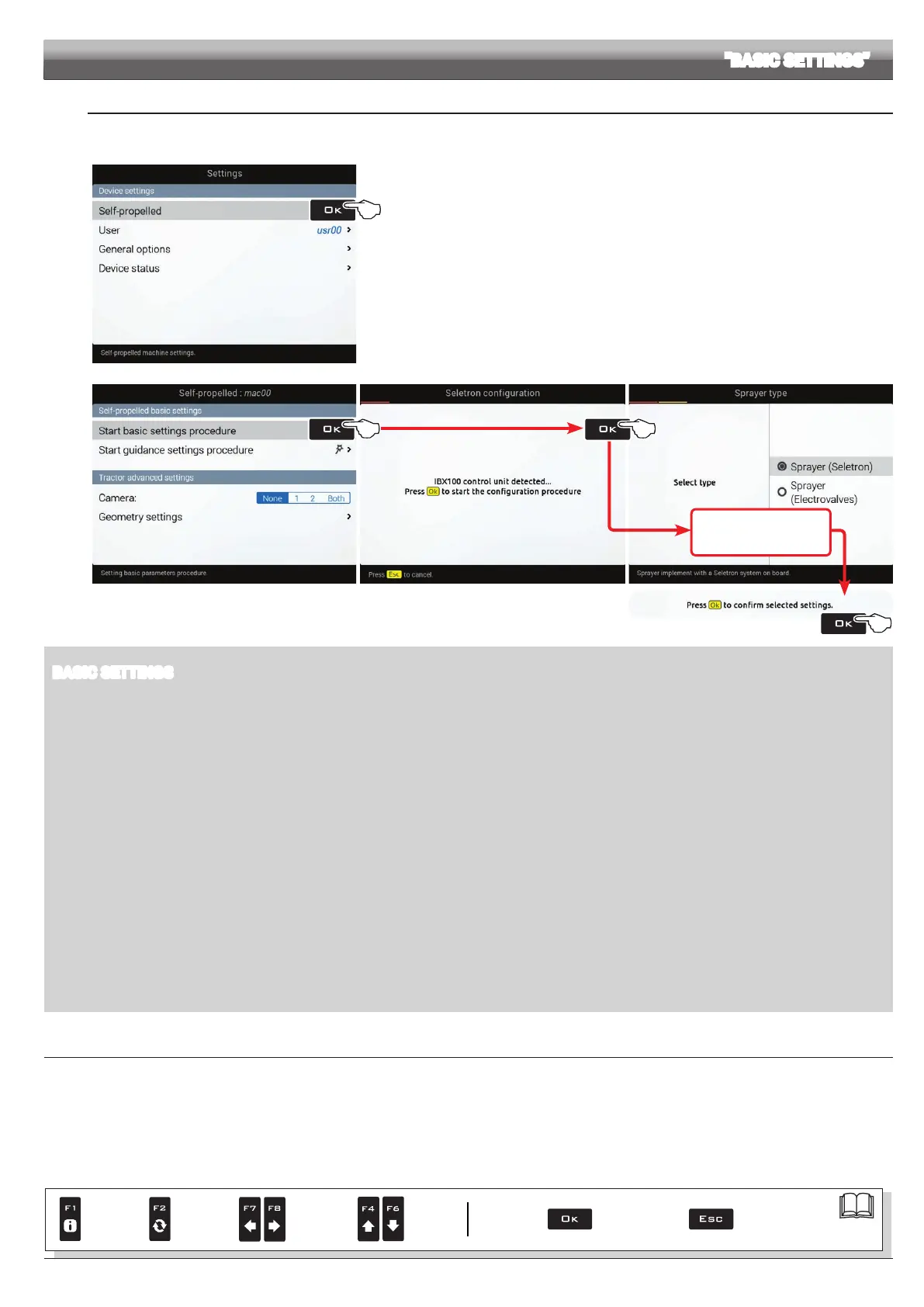

4A GUIDED SETUP PROCEDURE FOR SELF-PROPELLED MACHINES

- From the "Home" page press F8.

- Select

Self-propelled (Fig. 48) and press OK.

Fig. 48

Start basic settings procedure (Fig. 49)

- Delta 80 guides you through the setup procedure: follow all suggested steps and select required

options.

OK: next step ESC: previous step.

- When message

Press Ok to confirm selected settings,

is displayed, setup is completed. Press OK.

- Now select

Start guidance settings procedure and go to guided setup procedure Fig. 52.

Fig. 49 Fig. 50

OK Next step

ESC Previous step

Fig. 51

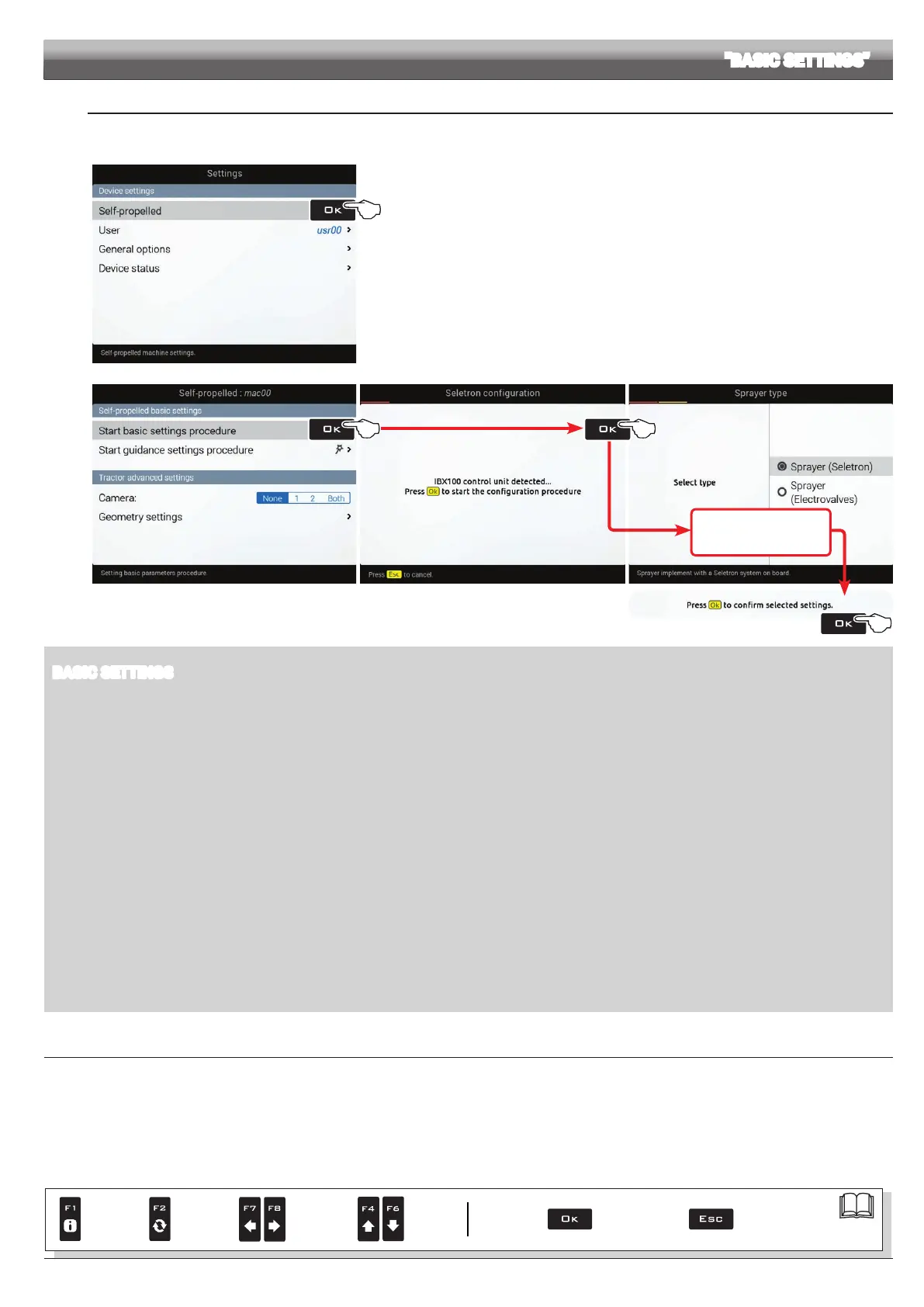

BASIC SETTINGS

• IMPLEMENT TYPE

Sprayer (Seletron)

: system with Seletron valves.

Sprayer (Electrovalves): system with electric-activated valves - with gearmotor.

• MAIN VALVE

Main control valve installed on the control unit:

None

2 ways (drain valve)

3 ways (main valve)

• SPRAYING SPOT TYPE

Seletron type: single, twin or fourfold

• FLOWRATE REFERENCE SENSOR

Device used to calculate owrate:

Flowmeter

Pressure sensor: measured pressure is used to calculate application rate.

Both: within the working limits the computer uses the owmeter, otherwise it uses the pressure sensor, ONLY if properly congured.

• TERMINAL NOZZLES

None

"Buffer zone" nozzles

: use switch panel to select nozzle to be used at "Buffer zone", see par. 12.2.1 "Buffer Zone" function enabled on page 74.

• TANK LEVEL SOURCE

Device used to read tank level:

Manual: no device connected

Filling flowmeter

Tank level sensor

CONTINUES

Loading...

Loading...