05-143

05 Engine

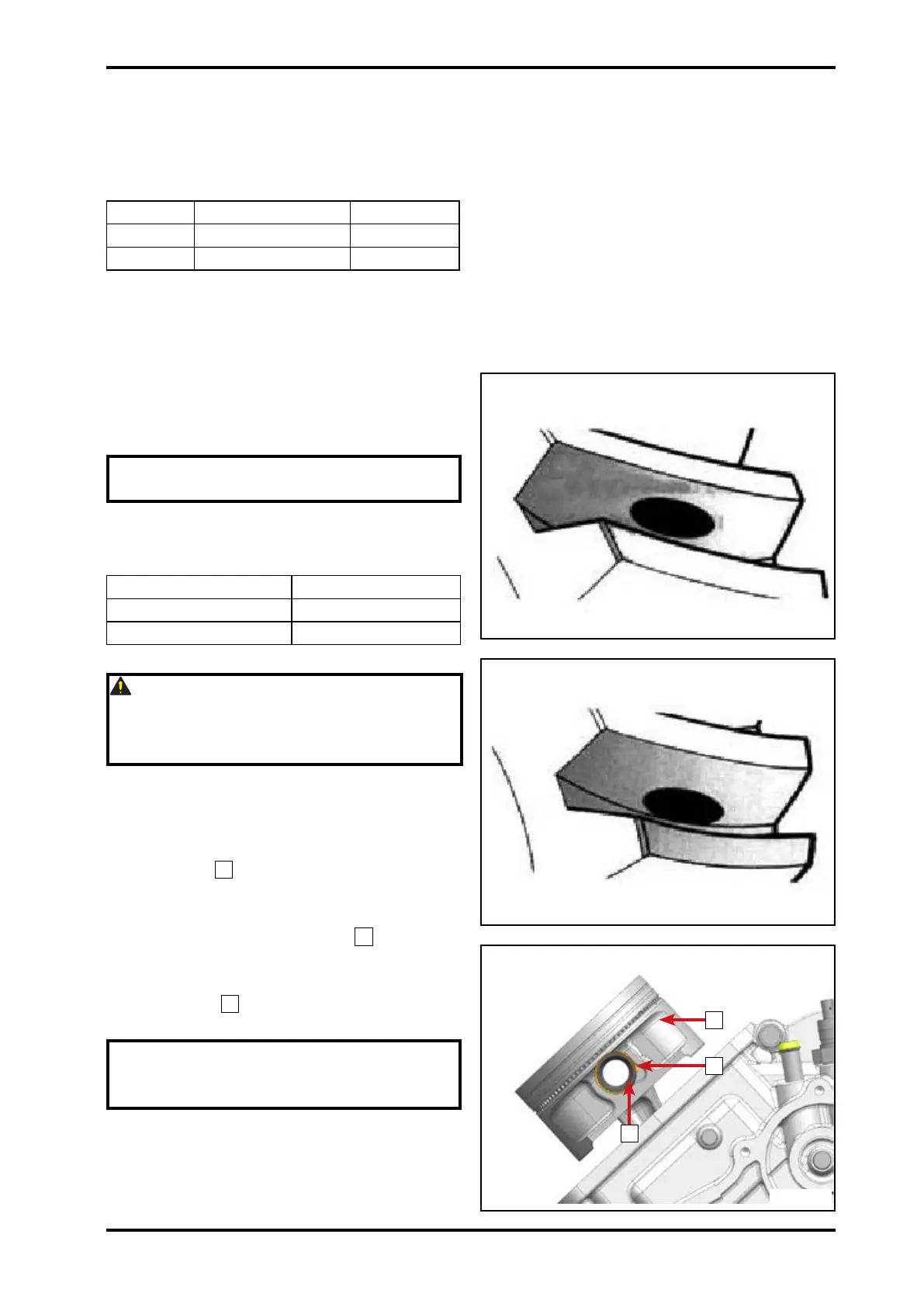

Rotate driven bevel gear several circles

forward and backward.

Remove drive and driven bevel gear assy

to see the dye coating results.

Status A On the top No

Status B In the middle Yes

Status C On the bottom No

If the teeth surface contact area is qualied

(Status B), continue following procedures.

If the teeth surface contact area is not

qualified (Status A or C), adjust the

thickness of drive bevel gear adjusting

washers. Repeat above procedures until

qualied.

NOTE: Clean the dye on gear teeth

after adjustment.

Adjusting Method

Contact condition Method

Status A Increase thickness

Status C Decrease thickness

CAUTION: After adjustment, measure

gear clearance again. If it is still not

qualified, replace drive and driven

bevel gear until it is qualied.

5.6.5 First Cylinder Body and Piston

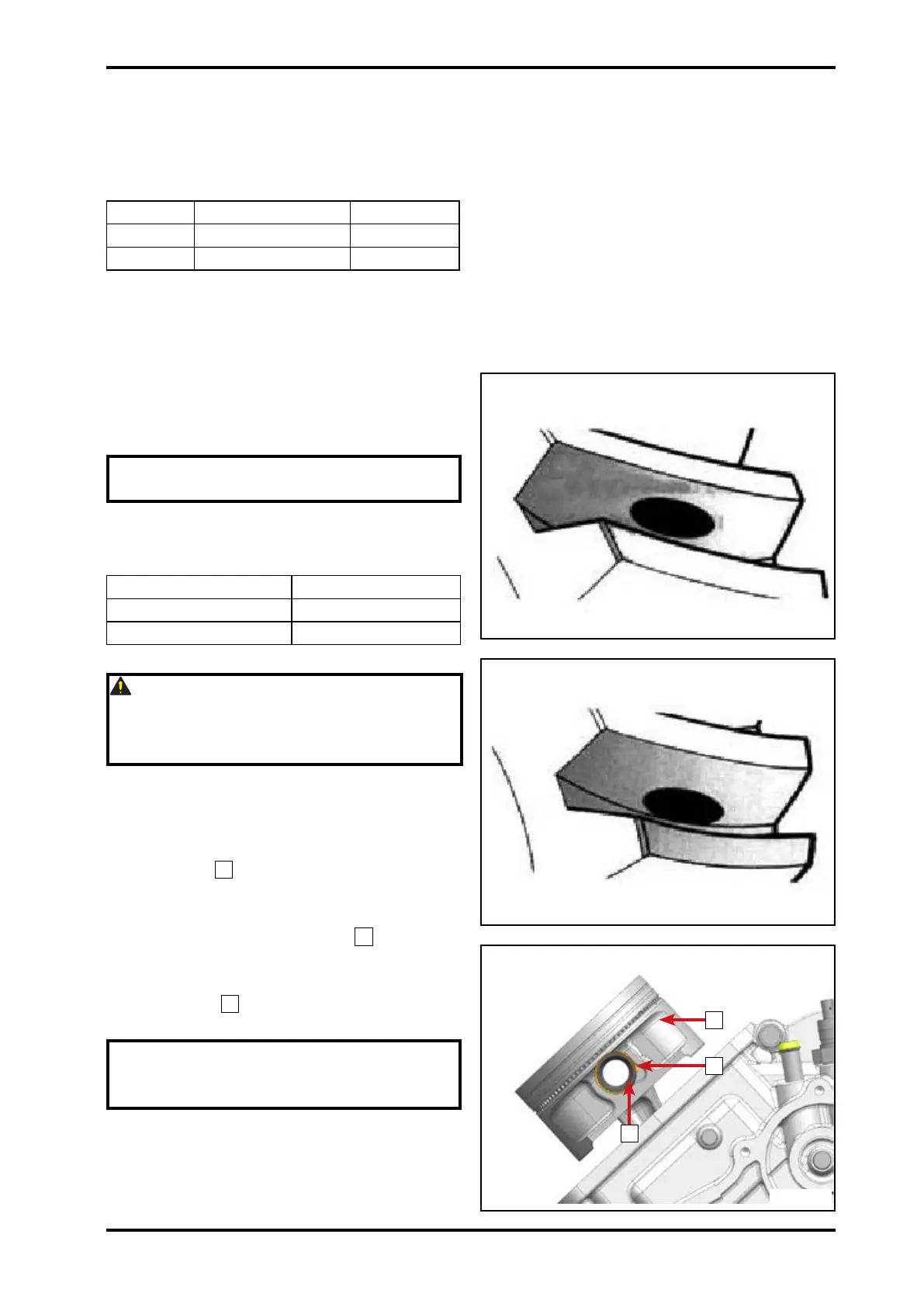

Rotate crankshaft to make the rst cylinder

connecting rod exposed.

Install piston

1

.

During installation, the "▲" mark on piston

should face towards the transmission.

Apply engine oil on piston pin

2

and insert

it into piston pin hole and connecting rod

small end hole.

Install circlip

3

. (The open of circlip and

the groove should be staggered.)

NOTE: Install pistons according to

the made marks, to prevent incorrect

installation.

3

2

1

059901

059902

059903

© CFMOTO Powersports, Inc. This manual is subject to all applicable copyright laws.

Reproduction or duplication in any form, whole or in part, is strictly prohbited.

Loading...

Loading...