CHAPTER 51

PAGE 28

PAGE DATE: 7. July 2010

MAINTENANCE MANUAL EXTRA 300LT

to the layer sequence plan. Ensure correct style and direc-

tion of fabric.

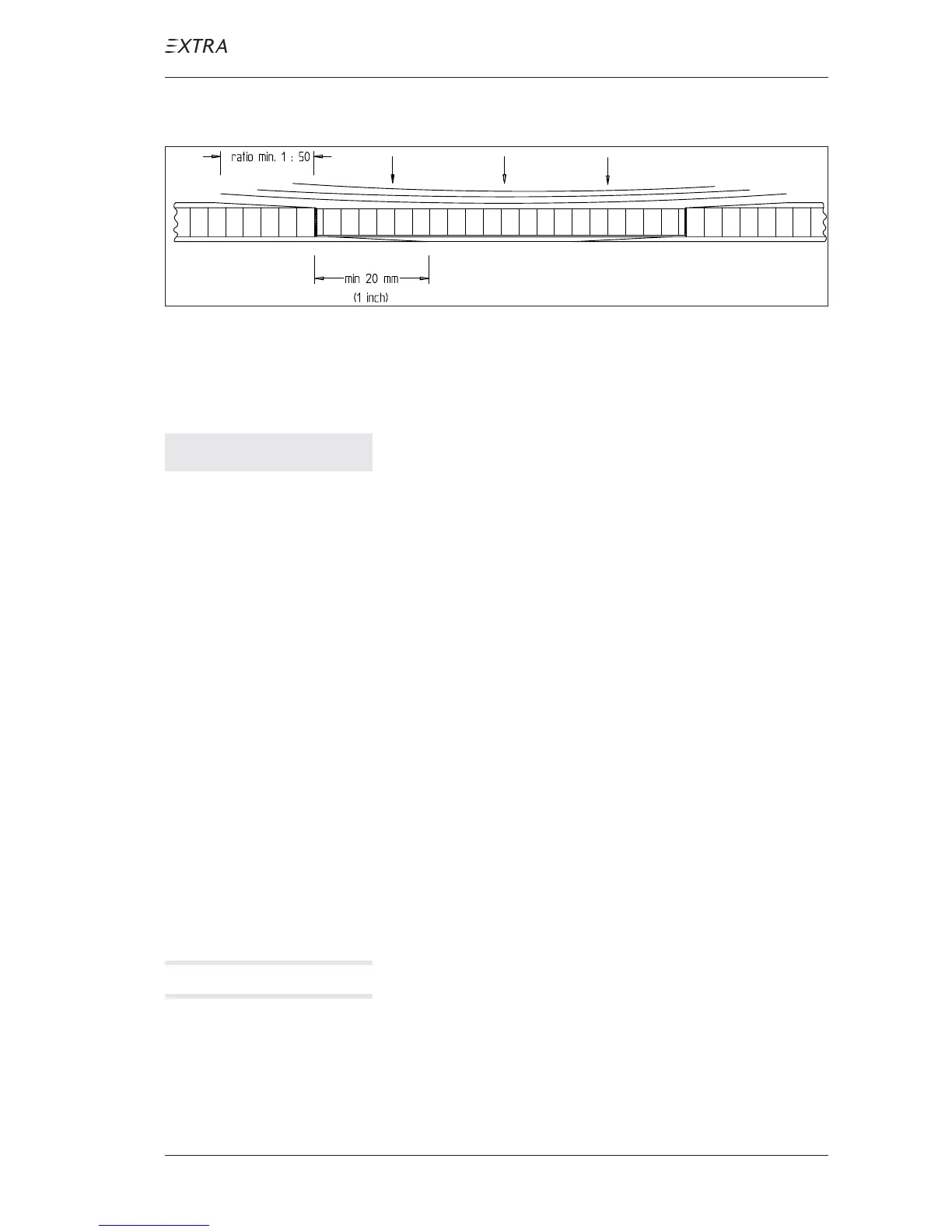

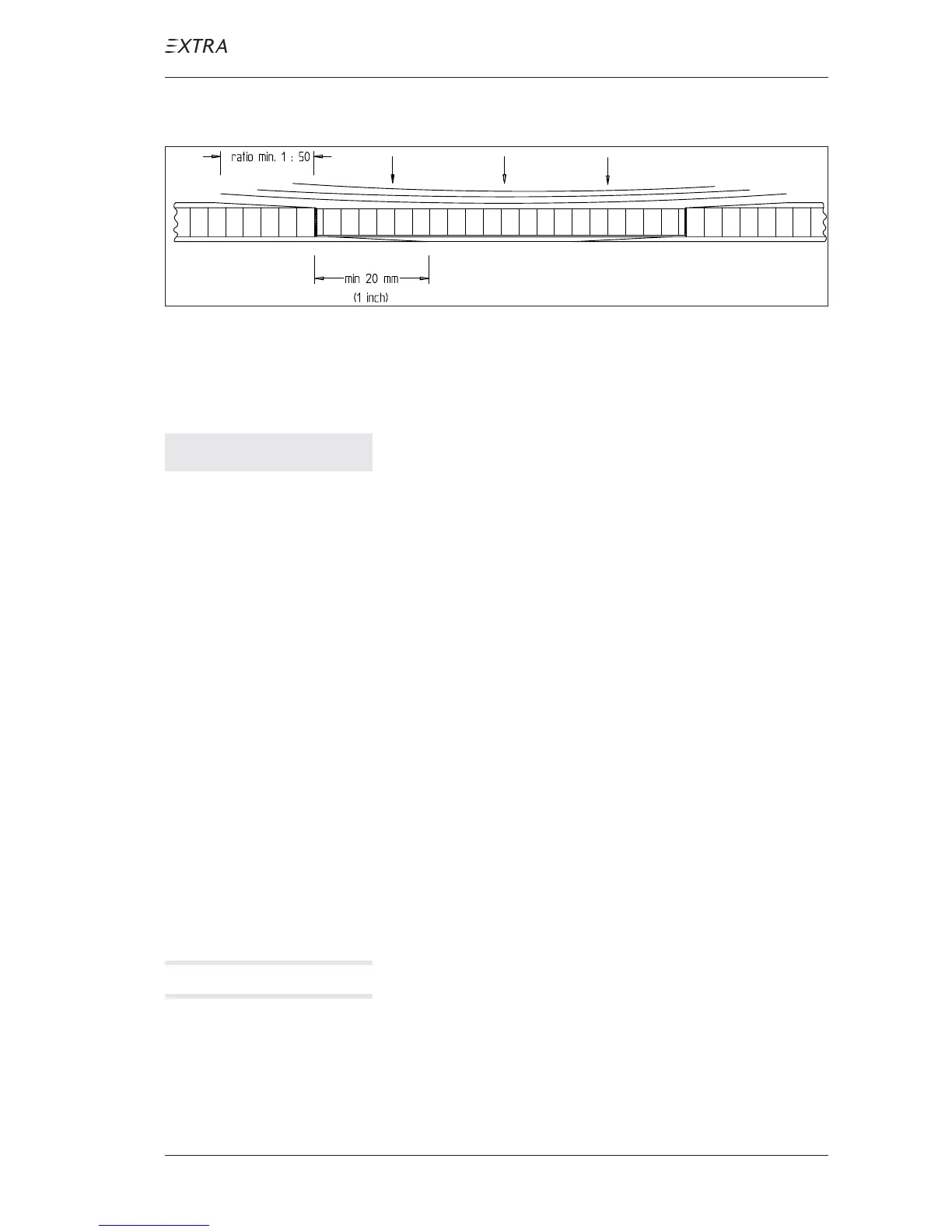

Figure 8 Damage of Complete Sandwich

Lay out the required number and size of fabric pieces on a

piece of plastic foil and wet them with resin mixture.

Subsequently, position them on the repair area.

I M P O R T A N T Remove the plastic foil after each positioning process.

The repair area has to be cured under condition of vacuum

bagging. Proceed as follows:

1 Apply peel nylon fabric on the last repair fabric layer.

2 Perforate a clean, thin plastic foil with a thick needle

(max. spacing of holes: 20mm x 20mm) - mainly in the

area of the honeycomb - and lay it on the repair area.

3 Lay a jute cloth or equivalent bleeder cloth on this

perforated plastic foil.

4 Lay a second plastic foil uppon the jute weave and seal

their edges to the surrounding surface using an adhesive

tape.

5 Apply suction with a vacuum pump (pressure approx.

0.7bar / 10psi).

6 Apply the thermal curing cycle.

7 Following the curing cycle carefully remove vacuum

bagging material and peel nylon fabric.

N O T E After the pre-curing period at room temperature, the

repaired area has to be cured according the tempera-

ture cycle as shown on Figure 6.

After the curing process is completed, the repair area can be

sanded level to the surrounding area.

Loading...

Loading...