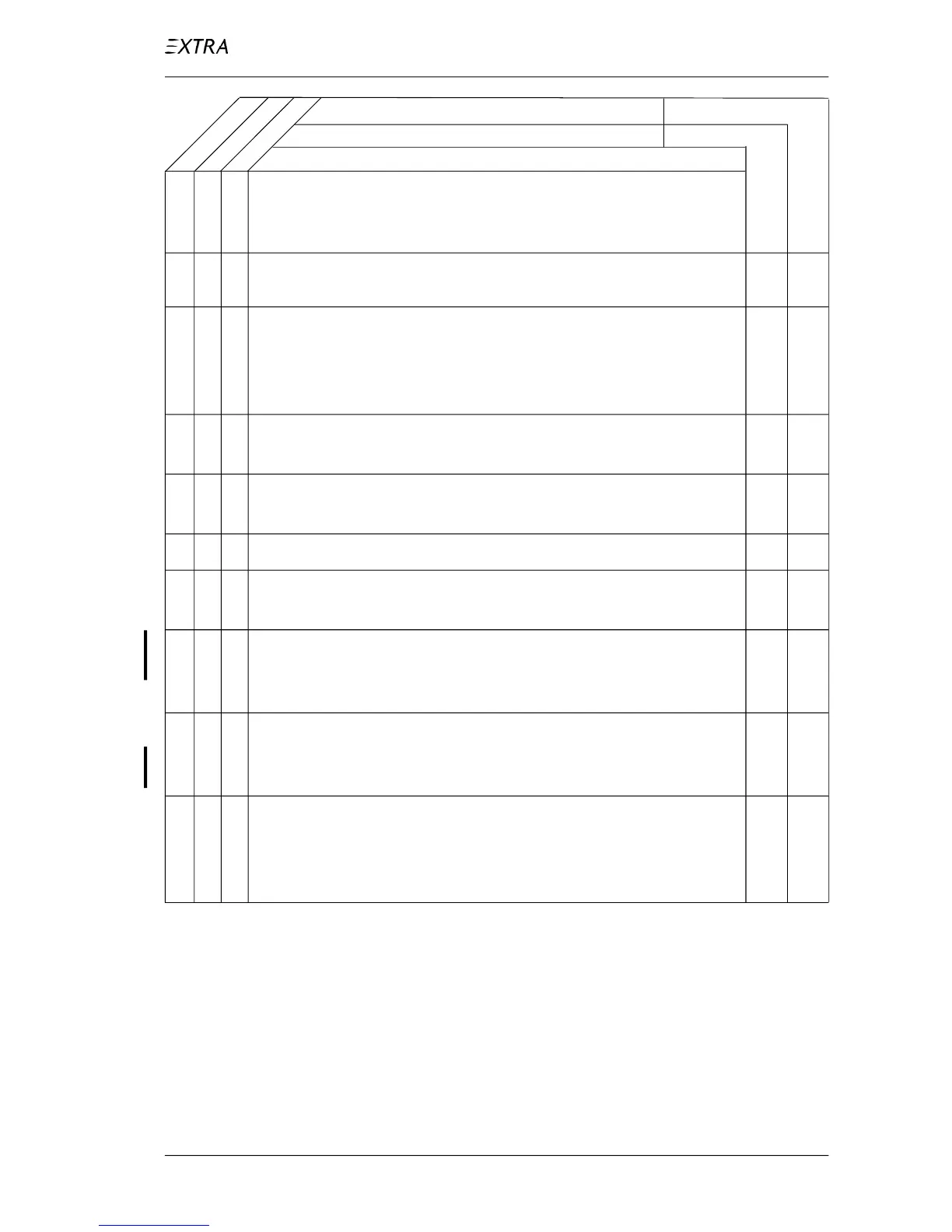

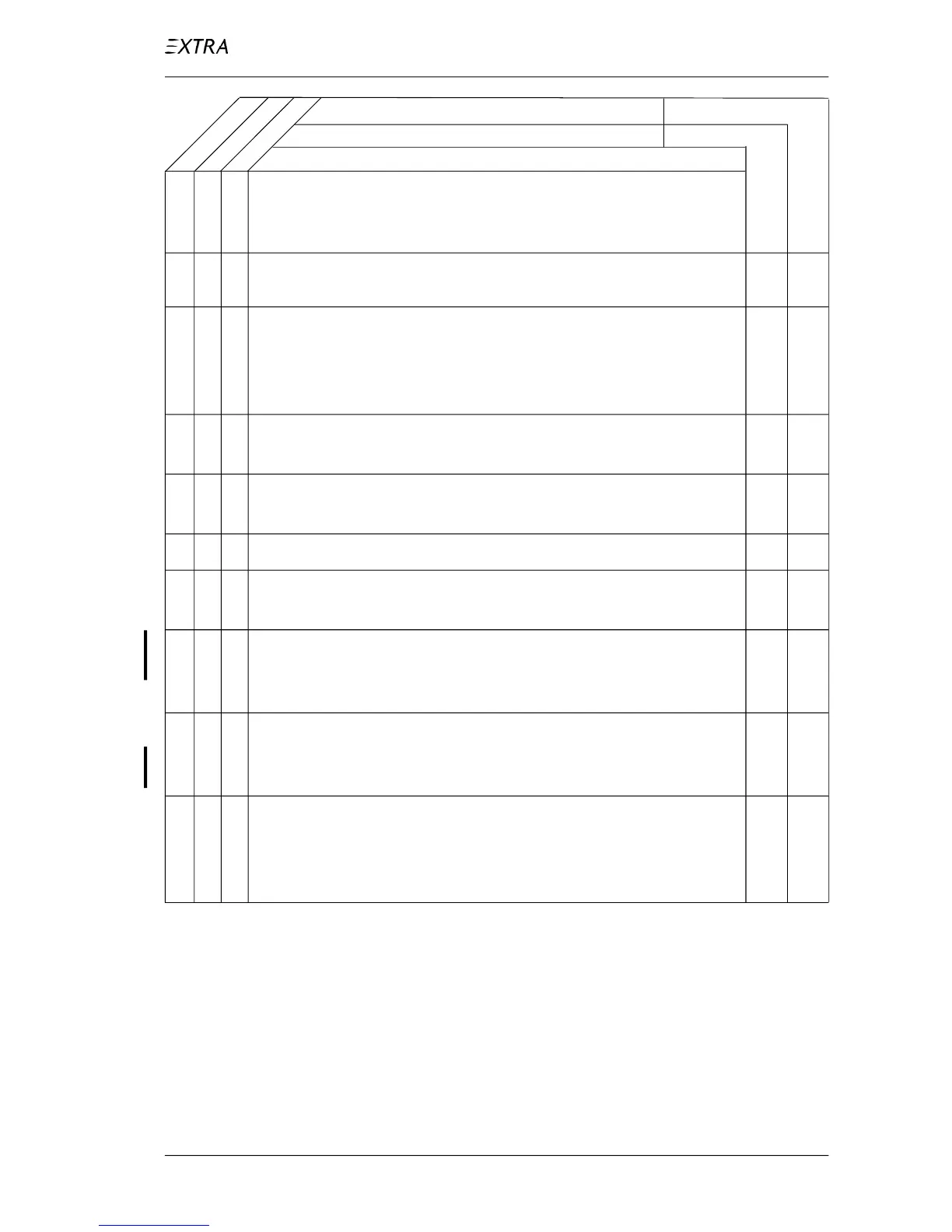

CHAPTER 5

PAGE 15

PAGE DATE: 12. June 2015

MAINTENANCE MANUAL EXTRA 300LT

Inspector:

Mechanic:

Date:

Serial No.:

Inspections

as specif

i

ed

eac

h

50 hours

eac

h

100 hours

O

1

15 Clean and flush the Inverted Oil System with a suitable

petroleum solvent, such as Varsol according to Lycoming

Operator’s and Maintenance Manual.

O

2

O O 16 Service engine with recommended lubricating oil in accord-

ance with chapter 12-10-04.

O O 17 Inspect condition of spark plugs (clean and adjust gap as

required, adjust per Lycoming Service Instruction 1042). If

fouling of spark plugs is apparent, rotate bottom plugs to

upper plugs and vice versa.

O O 18 Inspect spark plug cable leads and ceramics for corrosion

and deposits.

O O 19 Perform a hot engine differential compression check in

accordance with FAA AC 43.13-1A.

O 20 Inspect cylinders for cracked or broken fins.

O O 21 Check cylinders for evidence of excessive heat which is

indicated by discoloration.

O 22 Check fuel injector nozzles for loseness. Tighten to 6.8 Nm

(60 inch-pounds) torque. Check fuel lines for fuel stains

which are indicative for fuel leaks.

O O 23 Inspect rocker box covers for evidence of oil leaks. If

found, replace gasket; torque cover screws 5.7 Nm (50

inch-pounds).

O

3

24 Remove rocker box covers and check for freedom of valve

rockers when valves are closed. Look for evidence of ab-

normal wear or broken parts in the area of valve tips, valve

keeper, springs and spring seats.

SCHEDULED MAINTENANCE CHECKS

Maintenance Checks Schedule

1 each 300 hours

2 each 25 hours

3 each 400 hours

Loading...

Loading...