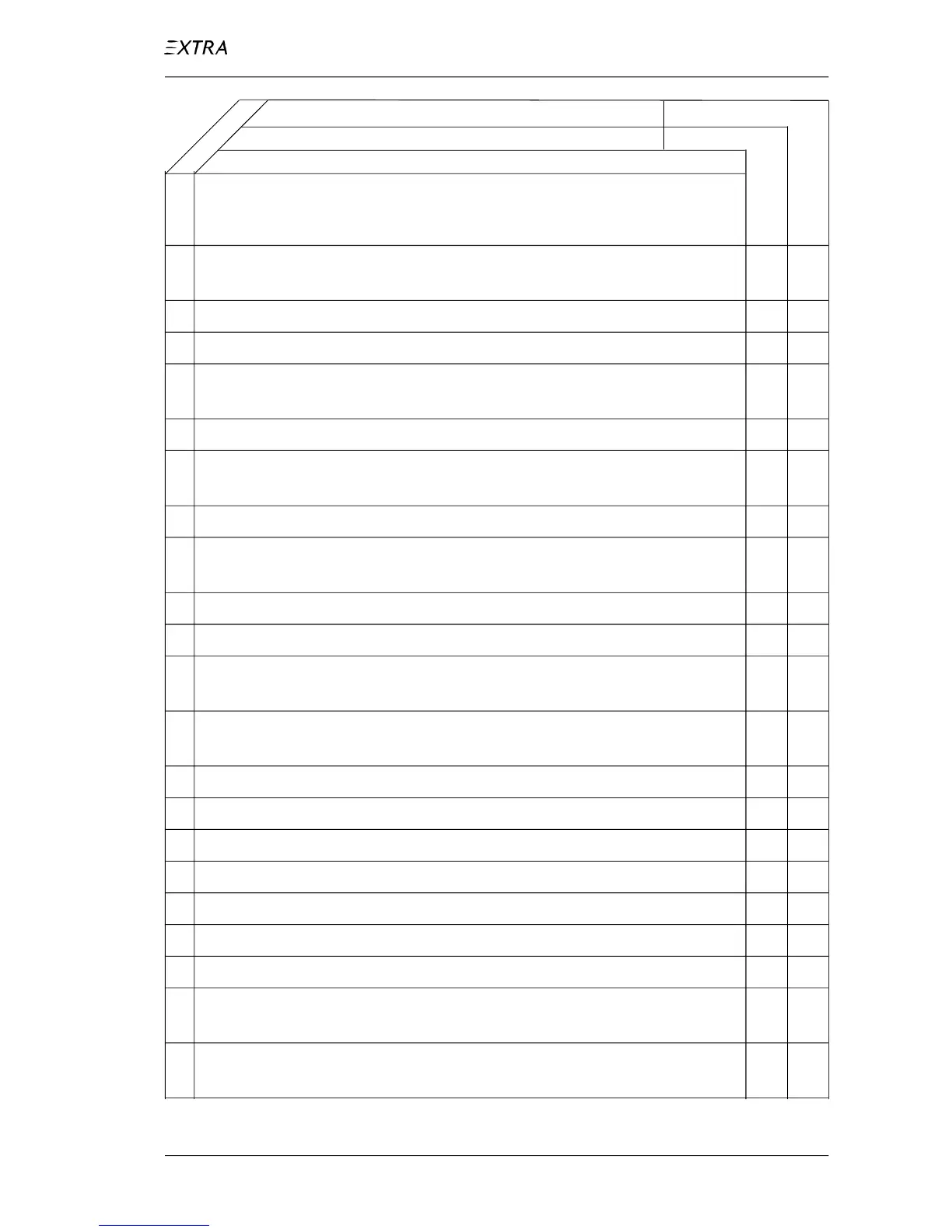

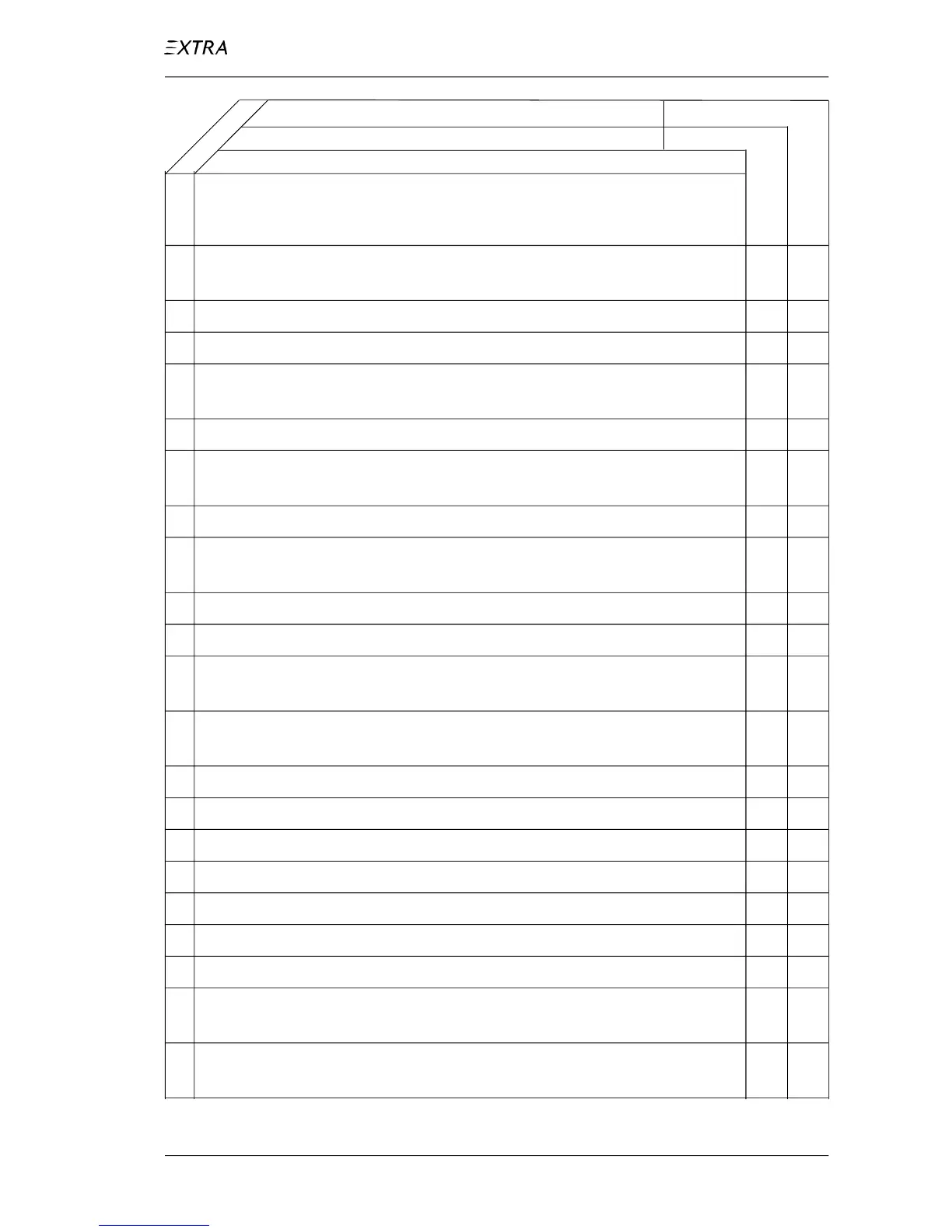

CHAPTER 5

PAGE 29

PAGE DATE: 7. July 2010

MAINTENANCE MANUAL EXTRA 300LT

O 13 Inspect aileron cantilever bearings for play. Check for free move-

ment and cleanliness.

O 14 Inspect attachment fitting for cracks, damage and corrosion. Check

for link bolts security.

Spar carry-through

O 15 Check main bolt sleeves for secure bonding to the spar.

O 16 Visually inspect spar for dents and cracks. Inspect for delaminations

by coin tapping.

Wing trailing edge

O 17 Check top to bottom shell bonding for cracks and delaminations by

coin tapping (refer to chapter 20-10-05).

Root and Tip

O 18 Check metall fittings (power supply support) for secure bonding to

the carbon laminate.

O 19 Inspect grounding wires, pitot/static hoses and attachments.

O 20 Inspect rivets of electrical bonding visually.

O 21 Inspect root rib for cracks, delaminations and insecure bonding to

skin and spars by coin tapping (refer to chapter 20-10-05).

O 22 Check tip area visually for general condition (inside by boroscope

through strobe/navigation light opening).

Surface general

O 23 Check paint visually for general condition (blisters etc.).

O 24 Check laminate for erosion, scratches and nicks.

O 25 Visual inspect for damage caused by footsteps.

Aileron

O 1 Check root and tip rib bonding to the skin laminate by coin tapping.

O 2 Check skin to spar bonding for delaminations by coin tapping.

O 3 Check top to bottom shell bonding for cracks and delaminations by

coin tapping (refer to chapter 20-10-05).

O 4 Check hinge points (mounting brackets) and actuator for damages

and cracks. Ensure proper attachment.

Inspector:

Mechanic:

Inspections

Date:

Serial No.:

1000 hours

SCHEDULED MAINTENANCE CHECKS

Significant Items Inspection

Loading...

Loading...