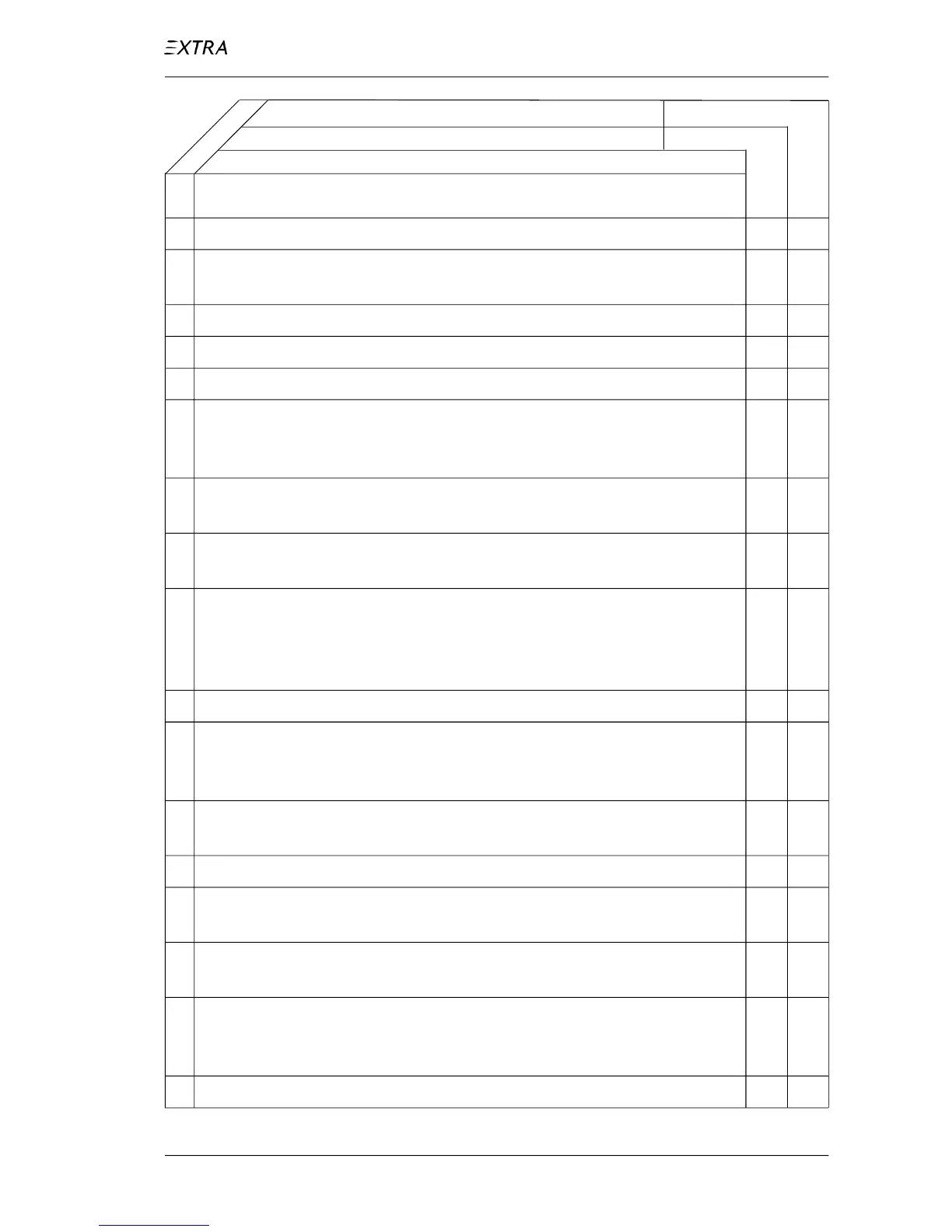

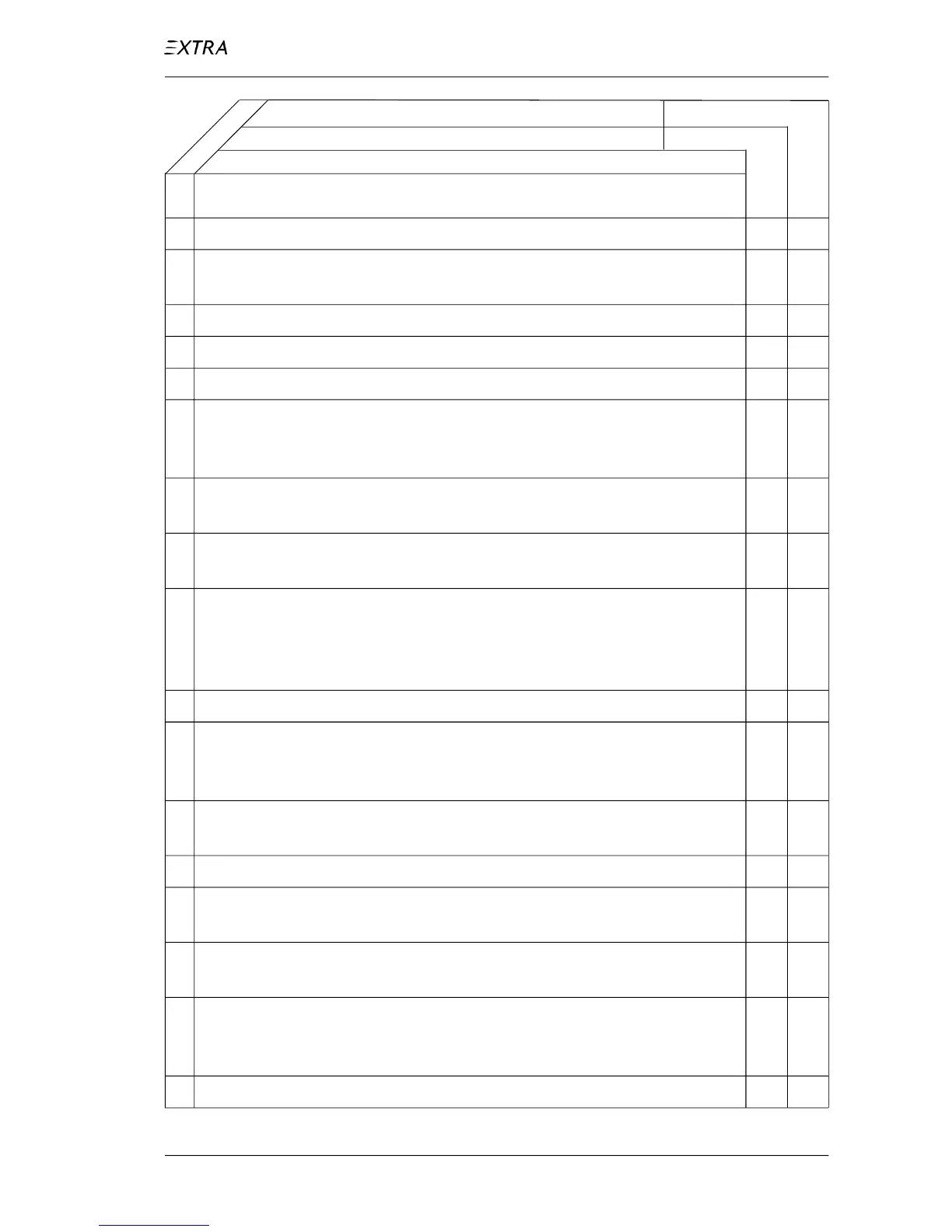

CHAPTER 5

PAGE 33

PAGE DATE: 7. July 2010

MAINTENANCE MANUAL EXTRA 300LT

Inspector:

Mechanic:

Inspections

Date:

Serial No.:

1000 hours

Surface general

O 11 Check paint for general condition (blisters etc.).

O 12 Check laminate for erosion, scratches, stone nicks and impact

damages.

O 13 Reinstall elevator actuator lever.

Fuselage

O 1 Remove cuffs, main and bottom fuselage cover as per chapter 53.

O 2 Inspect cuffs, main and bottom fuselage cover for soft areas, dents,

cracks, delamination, damaged screw holes and tearing of edges.

Inspect heat shield for cracks and loose rivets.

O 3 Inspect tubular steel frame visually for corrosion, scratches and

damages.

O 4 Check wing main spar attachment for damage and corrosion. Inspect

for dents and cracks.

O 5 Detailed visual inspection of the sheet metal of the wing auxiliary

spar attachment for damage, corrosion. Inspect the sheet metal

supports using a fluorescent dye penetrant to insure no cracks are

evident.

Control system

O 1 Detailed visual inspection of torque tube for damages, cracks, free-

play (especially in the rear torque tube bearing). Check travel stop

adjustments.

O 2 Inspect bell cranks for damage, corrosion, security of mounting and

link bolts through wing access holes.

O 3 Inspect control rods for corrosion.

O 4 Inspect rod end bearing for play. Check for free movement and

cleanliness.

O 5 Inspect control rods for loose or popped rivets, and bearing play.

Check for general condition.

O 6 Inspect control sticks (rear & front) for full travel, proper rigging,

free-play, security of mounting and direction of control surface

movement with relation to stick movement.

O 7 Check rod end bearings for free movement and cleanliness.

SCHEDULED MAINTENANCE CHECKS

Significant Items Inspection

Loading...

Loading...