Operating manual.

CNC 8060

CNC 8065

26.

KINEMATICS CALIBRATION.

Tables to modify type 1 to 16 kinematics to vector kinematics.

·478·

(REF: 1807)

26.2 Tables to modify type 1 to 16 kinematics to vector kinematics.

For type 1 to 16 kinematics, if the cycle has not correctly calibrated any vector, it is

recommended to redefine the kinematics as vectors (type 50 to 51) and repeat the

calibration. The following tables show how to redefine type 1 to 16 kinematics as vector

kinematics. If the cycle has properly calibrated the kinematics, no transformation is

necessary.

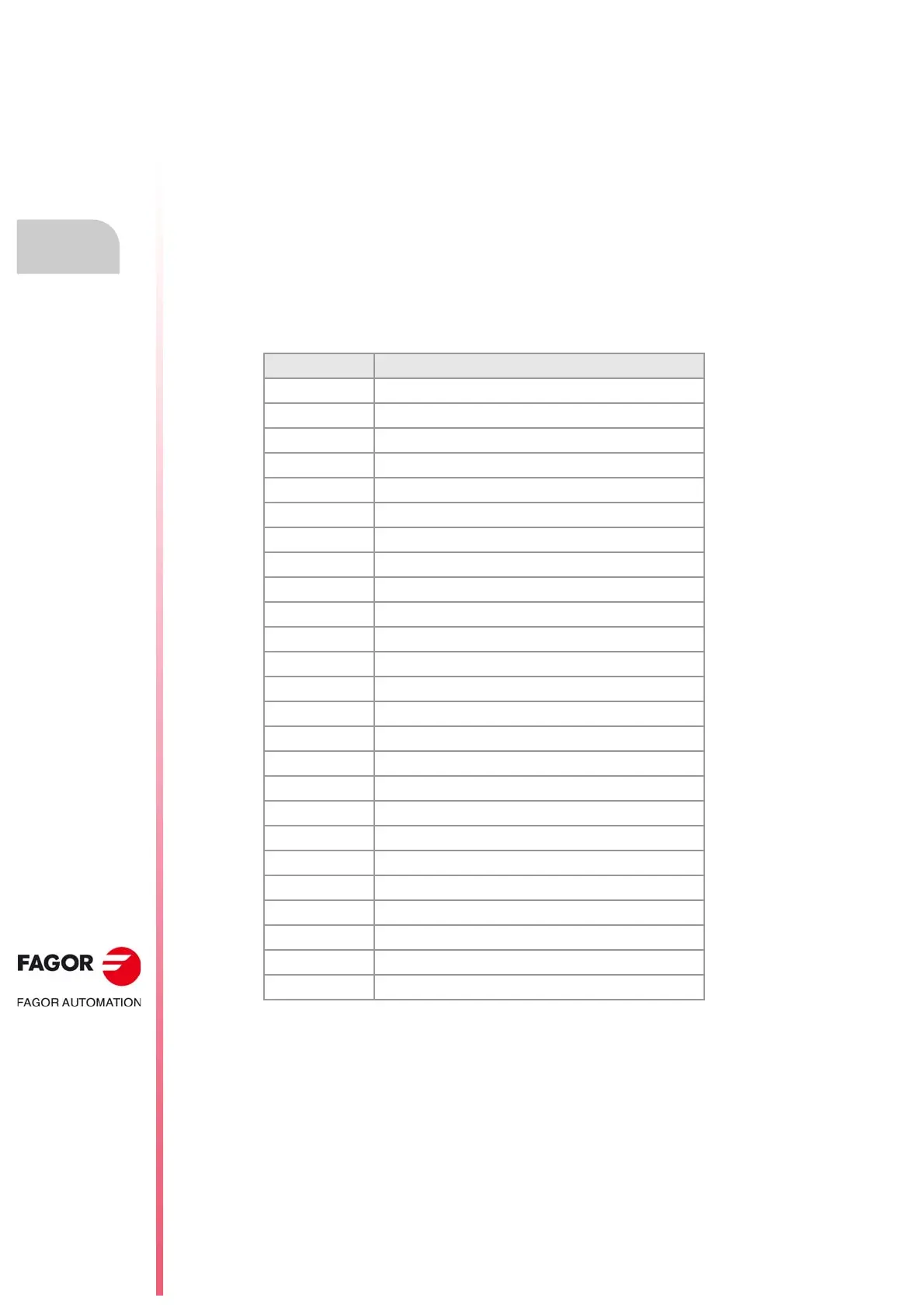

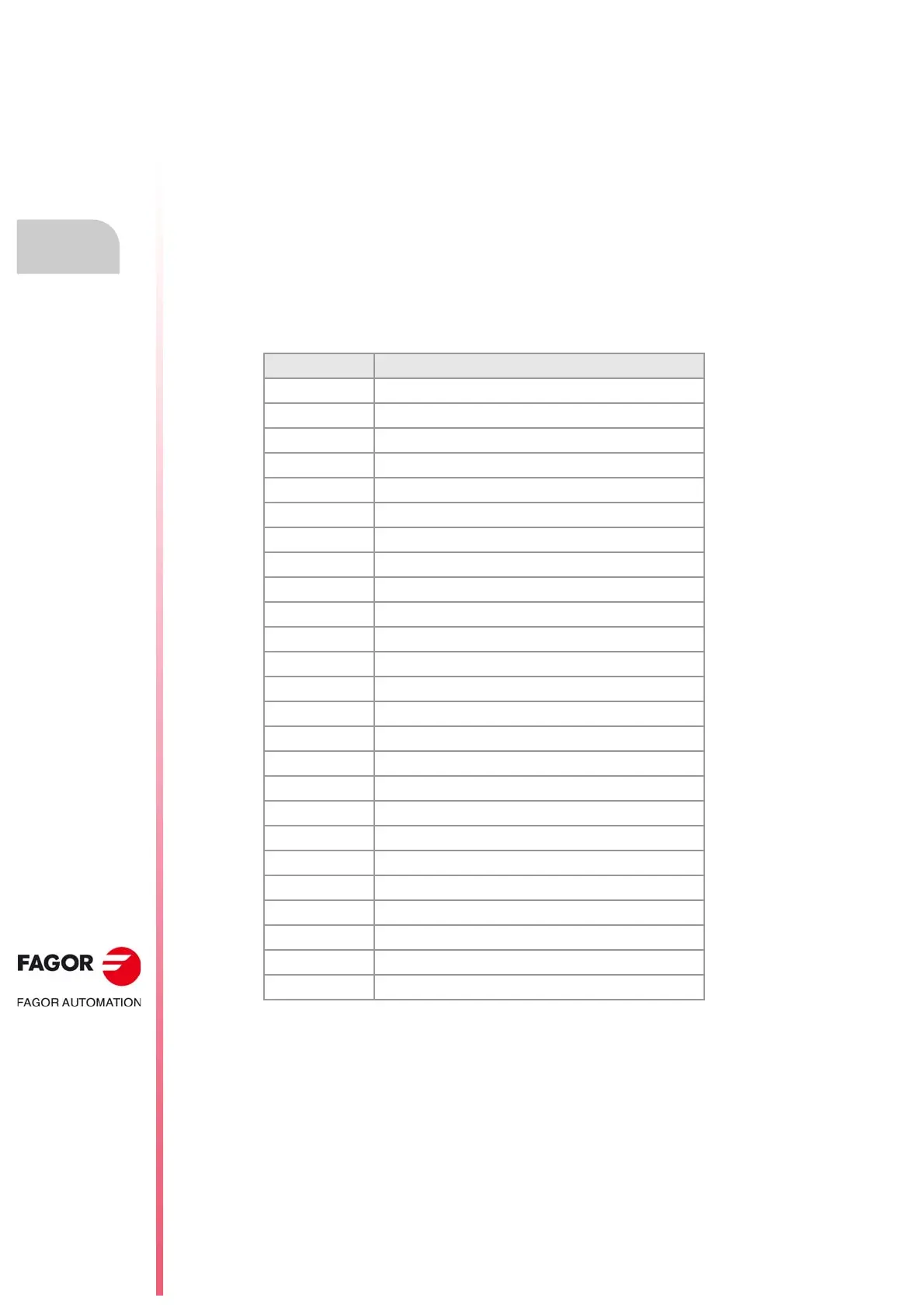

26.2.1 Adapting a type 1 kinematics to a type 50 kinematics.

The first column indicates the parameters of the vector kinematics and the second column

the value or parameter of the equivalent type 1 kinematics. Define the values of the second

column with the TDATA parameters of the first column (vector kinematics).

Type 50 Value or equivalent parameter for type 1 kinematics.

TYPE 50

TDATA1 TDATA13

TDATA2 TDATA3

TDATA3 TDATA15

TDATA4 0

TDATA5 1

TDATA6 0

TDATA7 TDATA8

TDATA8 TDATA10

TDATA9 0

TDATA11 TDATA2

TDATA12 0

TDATA13 TDATA4

TDATA14 1

TDATA15 0

TDATA16 0

TDATA17 TDATA9

TDATA18 TDATA11

TDATA19 0

TDATA21 0

TDATA22 TDATA6

TDATA23 TDATA1

TDATA24 0

TDATA25 0

TDATA26 1

Loading...

Loading...