Operating manual.

CNC 8060

CNC 8065

3.

HOW TO OPERATE THE CNC

Operating modes

·72·

(REF: 1807)

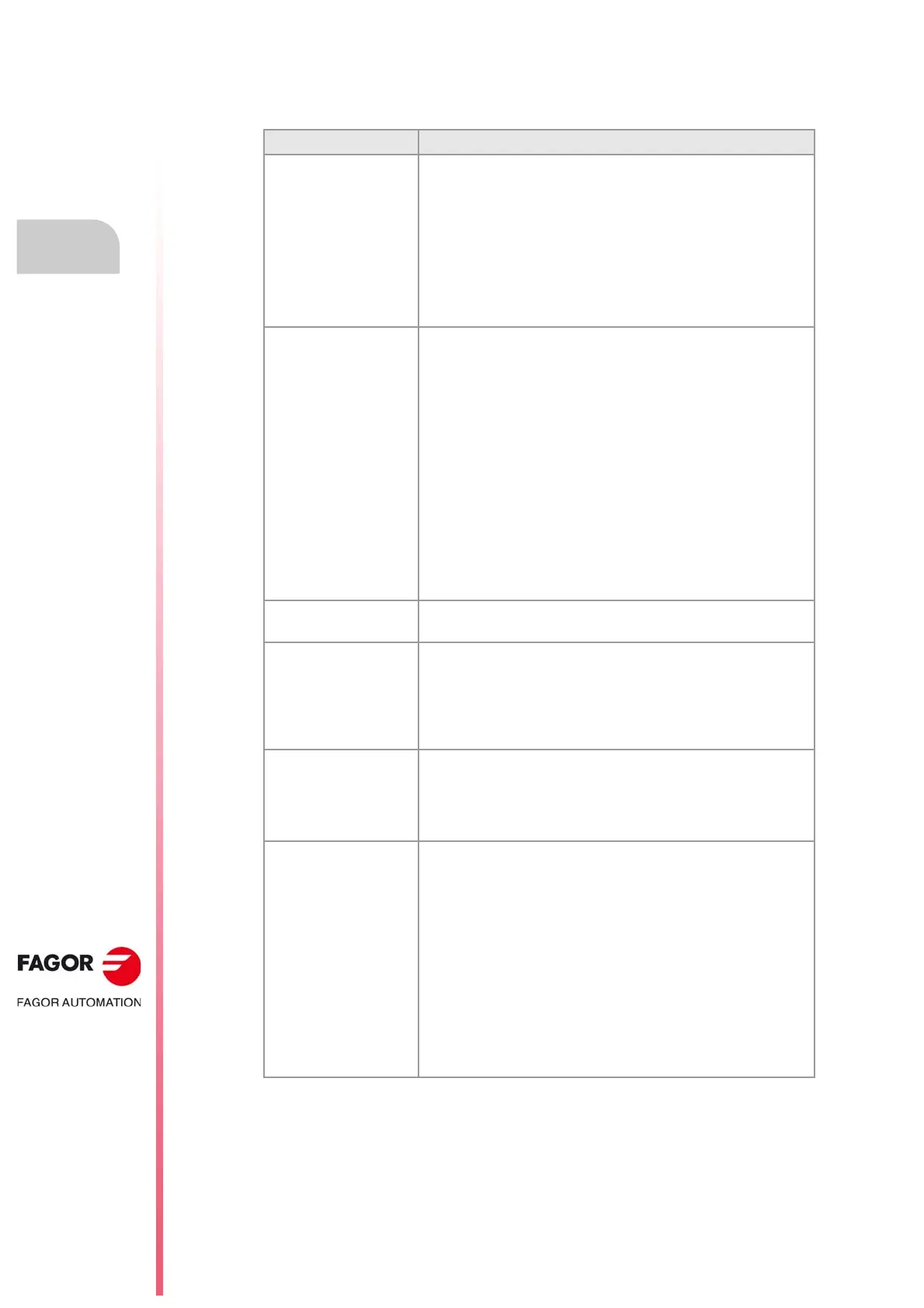

3.4.1 Description of the various operating modes

The CNC offers the following operating modes.

Operation mode. Operations allowed.

Automatic mode • Display the data regarding axis position, "M" and "G" function history,

active tool, spindle speed, axis feedrate, etc.

• Execute a part-program in "single block" or "automatic" mode.

• Set the execution conditions (first and last blocks) before executing

the program.

• Searching a block. Recover the history of a program up to a particular

block, with the option to change the active F, S, M and H functions

and resume program execution from that block.

• Show a graphic representation of the program being executed.

• Perform a tool inspection while executing the program.

Manual (jog) mode • Display the data regarding axis position, "M" and "G" function history,

active tool, spindle speed, axis feedrate, etc.

• Home the axes (Machine reference zero search).

• Jog the axes with the handwheels or with the JOG keys.

• Move an axis to a position by previously selecting the target point.

• Preset a coordinate.

• Act upon the master spindle using the Jog keyboard.

• Change tools.

• Activate external devices of the machine using the keys of the upper

side of the operator panel. The external devices associated with

each key must be defined by the machine manufacturer.

• Calibrate a tool in jog mode (without probe), in semi-automatic mode

(when using a table-top probe) or using the tool calibration cycle

(also when using a table-top probe).

• Part centering (mill model).

• Turn the CNC off from the softkey menu.

MDI/MDA mode • Edit and execute individual program blocks.

• Save the set of blocks executed as an independent program.

EDISIMU mode

(editing and simulation)

• Edit, modify or view the contents of a part-program.

• Simulate the execution of a program displaying a graphic

representation of the program being simulated.

• Estimate the total program execution time and the machining time

for each tool.

• Syntax test of the program.

User tables • Edit and modify the tables for zero offsets, fixtures and arithmetic

parameters.

• Save the content of a table.

• Recover the content of a table.

• Print the content of a table.

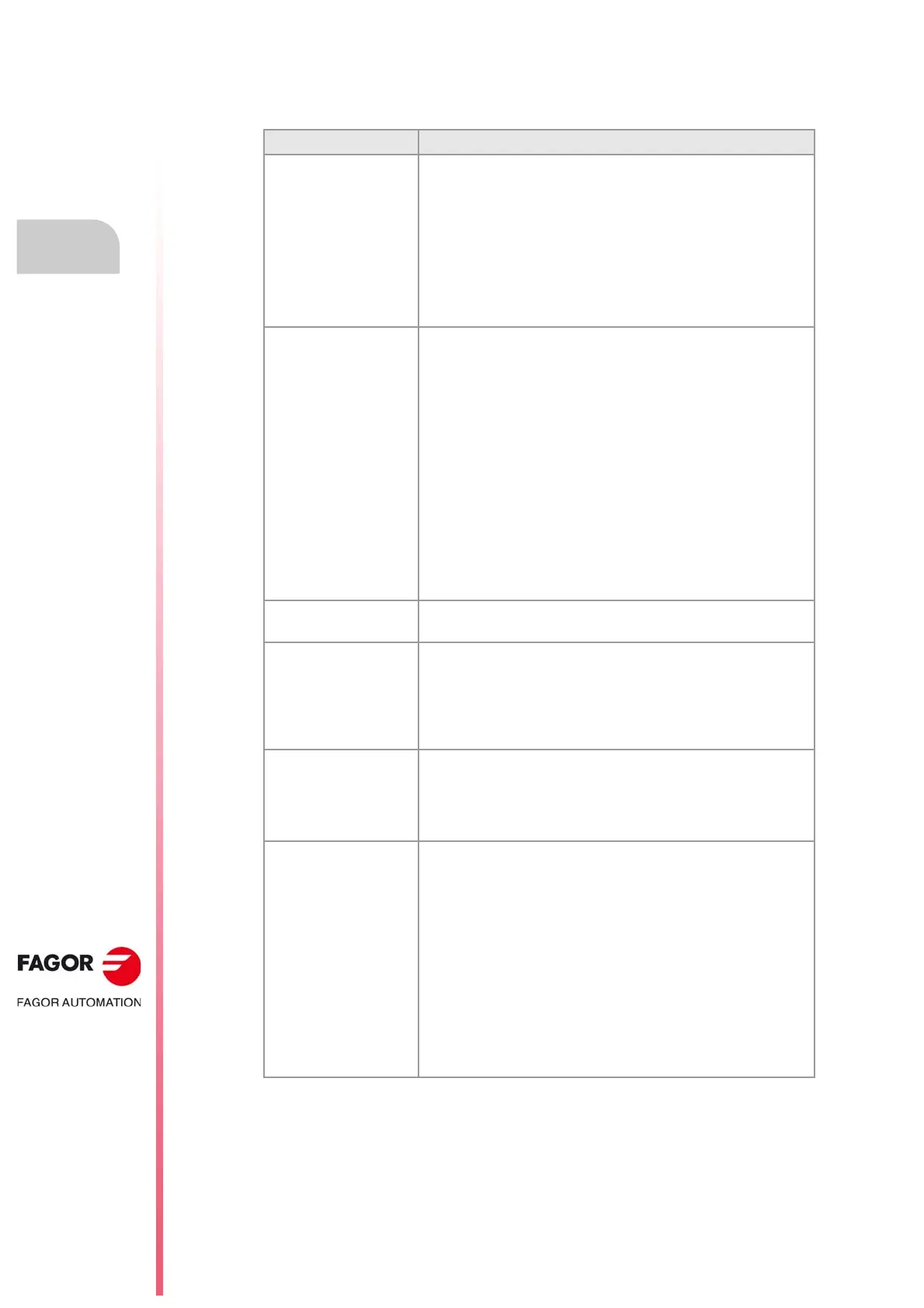

Tool table

Magazine table

• Editing and modifying the tool table

• Editing and modifying the tool magazine table. Display and manage

the tool arrangement in the magazines and in the tool changing arms

(if any).

• Display the information about the tool change process; the operation

carried out when executing an M06, manager status, change status

(in execution or at rest), magazine involved in the change (if the

change is taking place) and whether the change process is or not

in an error state.

• Load and unload a tool from the magazines through the spindle,

using a maneuver.

• Saving the table contents.

• Recalling the table contents.

• Printing the table contents.

Loading...

Loading...