Operating manual.

CNC 8060

CNC 8065

3.

HOW TO OPERATE THE CNC

Windows for warnings and errors

·76·

(REF: 1807)

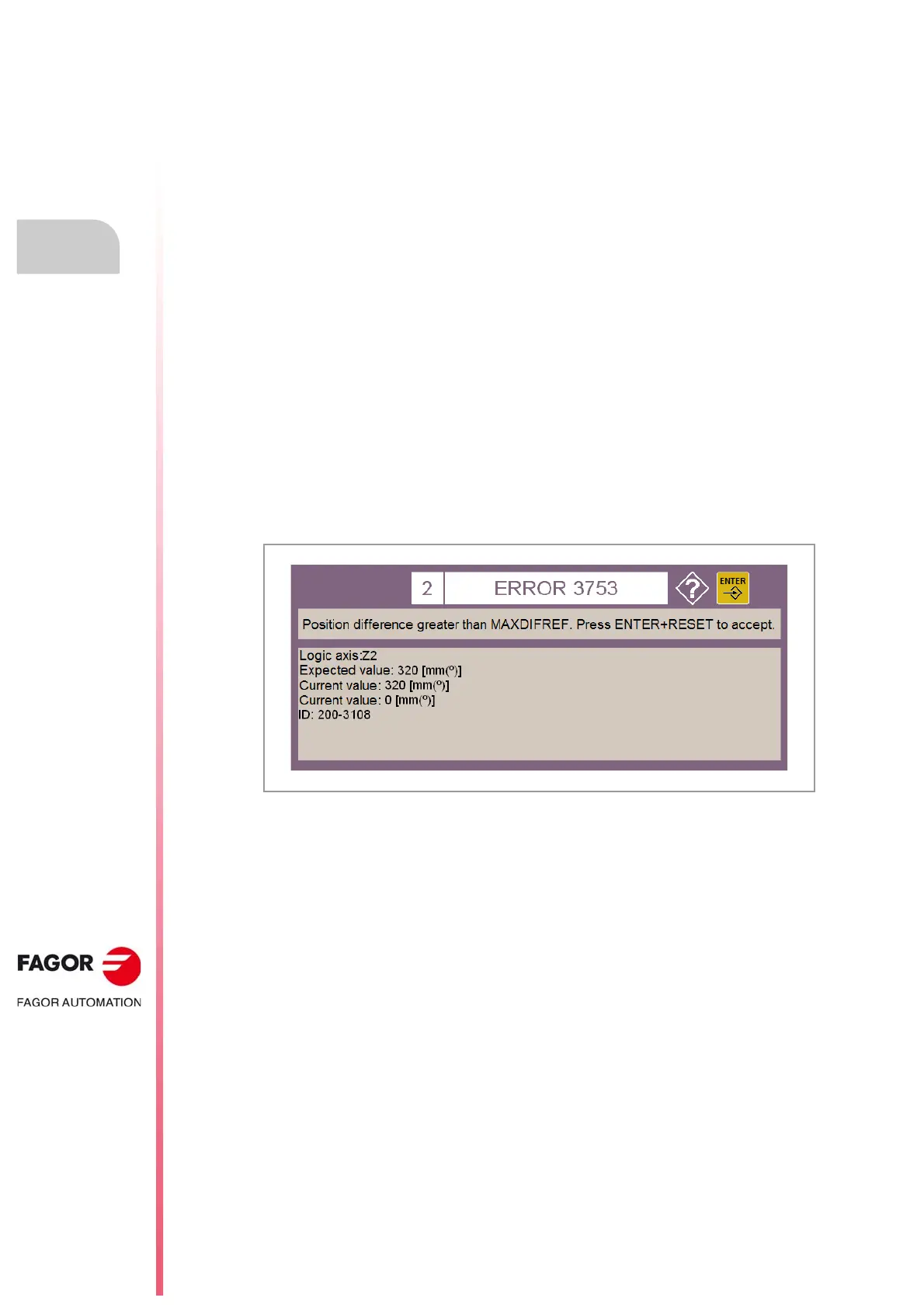

3.6.2 Error 3753. Absolute encoder. Monitor the coordinate difference during

startup (parameter MAXDIFREF).

When the axis has an absolute encoder, during startup the CNC takes into account the

number of encoder overshots to calculate the corresponding startup coordinates. Also, for

rotary axes, the CNC inserts the coordinates in the module and within the limits.

The CNC compares the position calculated for startup with that saved during shutdown, and

if there is any difference this may be because the axis had been moved after the CNC had

shutdown or due to a absolute feedback failure. The parameter MAXDIFREF indicates the

maximum allowable difference between the coordinate saved by the CNC and that read by

the encoder at startup.

• If the difference is less than the MAXDIFREF, the CNC starts up with the new position

calculated by the encoder and sets the mark PLC REFPOIN = 1, indicating that it is not

necessary to home the axis.

• If the difference is greater than the MAXDIFREF, the CNC will start up using the position

saved by the CNC at shutdown and display error 3753. The CNC will show this error in

a purple window, being the first one on the list, so that the user is aware of the situation

and determine the validity of the coordinates.

The coordinate is valid if the position of the machine coincides with the “current value”

field of the error. The user must clear the error by pressing [ENTER]+[RESET]; pressing

only [RESET] will not clear the error.

The coordinate is valid if the position of the machine coincides with the “expected value”

field. The user must clear the error by pressing [ENTER]+[RESET] and execute a G174

in MDI with the expected value. Afterwards, the CNC must be started-up to assume the

coordinate correctly.

Loading...

Loading...