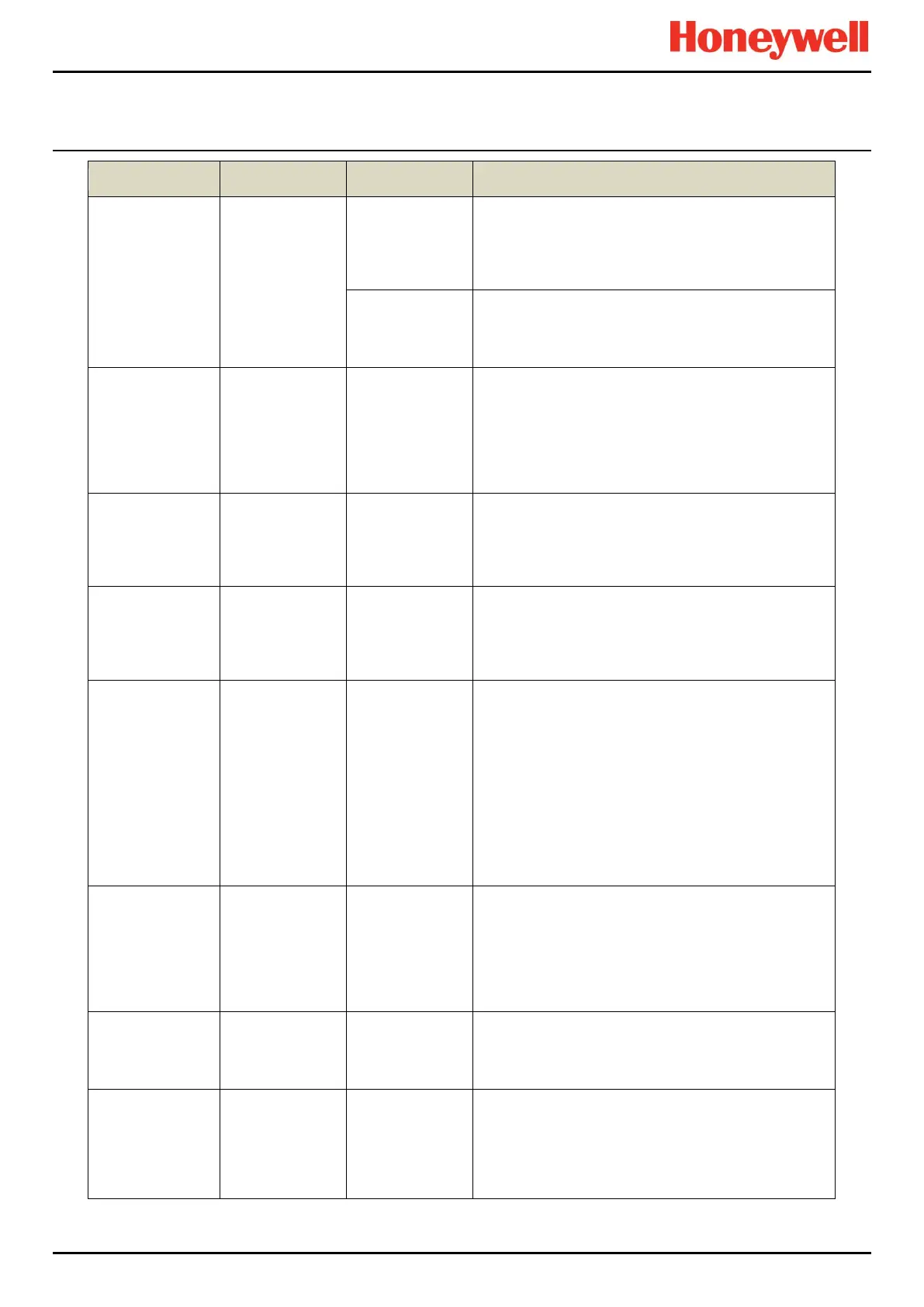

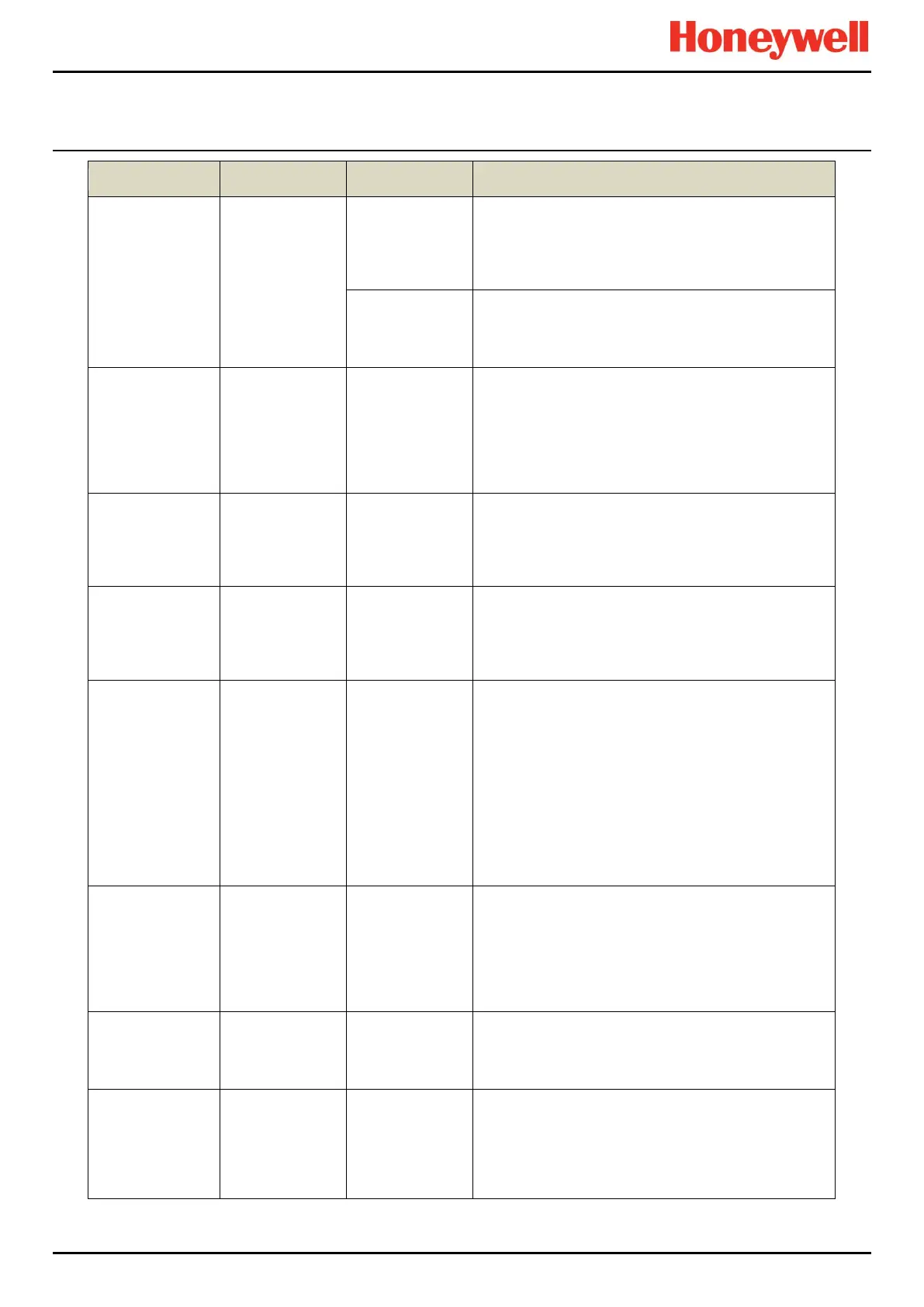

TROUBLESHOOTING

Part. No. 2400M2501_6 Touchpoint Pro

144 Technical Handbook

Wait for the Inhibit Delay time to elapse. (If the Power-

On Delay or Fault Recovery Delay is enabled, the

system will remain in Inhibit for a period defined by the

Inhibit Delay Time.) Please refer to Ch. 9.3.13 Inhibit

Delay Settings

Sensor /

Transmitter is

signalling Inhibit

The Sensor / Transmitter may be in a start-up

sequence, or may have been inhibited for maintenance.

Refer to the Input Details for that channel from the

Inputs screen.

There is a

discrepancy

between the

sensor reading

and the value

displayed by

Touchpoint Pro

The mA loop

requires

calibration

Touchpoint Pro converts the 4-20 mA signal it receives

from the sensor to a gas reading. If the discrepancy is

significant,

re-calibrate the 4-20 mA loop by forcing the sensor

output to 4 mA then 20 mA, see Commissioning,

Calibrating a mA input channel

Error ‘Calibration

Signal Too High’

occurs when

calibrating the mA

loop

The parameter

‘Maximum Span

Signal’ has been

exceeded (default

value 20 mA)

Review the configuration of the channel. Under

Calibration Settings, verify the value Maximum Span

Signal. If necessary, use a lower forced mA value to

calibrate the channel. Verify that the transmitter is

operating correctly.

HART

communication

with the

corresponding

field device

HART communication with the field device may appear

as a fluctuation on the incoming signal. This will clear

when HART communication ceases.

Verify that the system has a Bus Interface Board (BIB)

fitted. Check the wiring between the Control Module

terminal blocks TB6 and TB7 and the host computer

system port. Try swapping over TDA and TDB.

Check that the serial communication configuration

parameters of the host computer system and

Touchpoint Pro are the same.

Ensure that the bus is correctly terminated. If this is the

case remove the bus terminators and retry

communication.

Consider adding network bias resistors. Please refer to

Ch. 11 Configuring Modbus for further details.

Communication

data errors

Check the data signal wiring is not routed near sources

of electrical noise. Check for earth loops. Ensure that

the bus is correctly terminated. If this is the case remove

the bus terminators and retry communication.

Consider adding network bias resistors.

If possible use an oscilloscope to examine the signals

on the highway and take appropriate corrective action.

No response from

Touchpoint Pro

Check the address parameter used in requests issued

by the host computer system matches the address

allocated to the slave node. In multi-drop systems check

that all nodes have a unique address.

Module is still

showing as

present and

available for

configuration in

the System Setup

Module has not

been properly

removed from the

system

Follow the instructions to remove a module from the

system, see Maintenance, How to Remove or

Decommission an I/O Module

Loading...

Loading...