4-98 4222983 Second Edition

ELECTRICAL

4

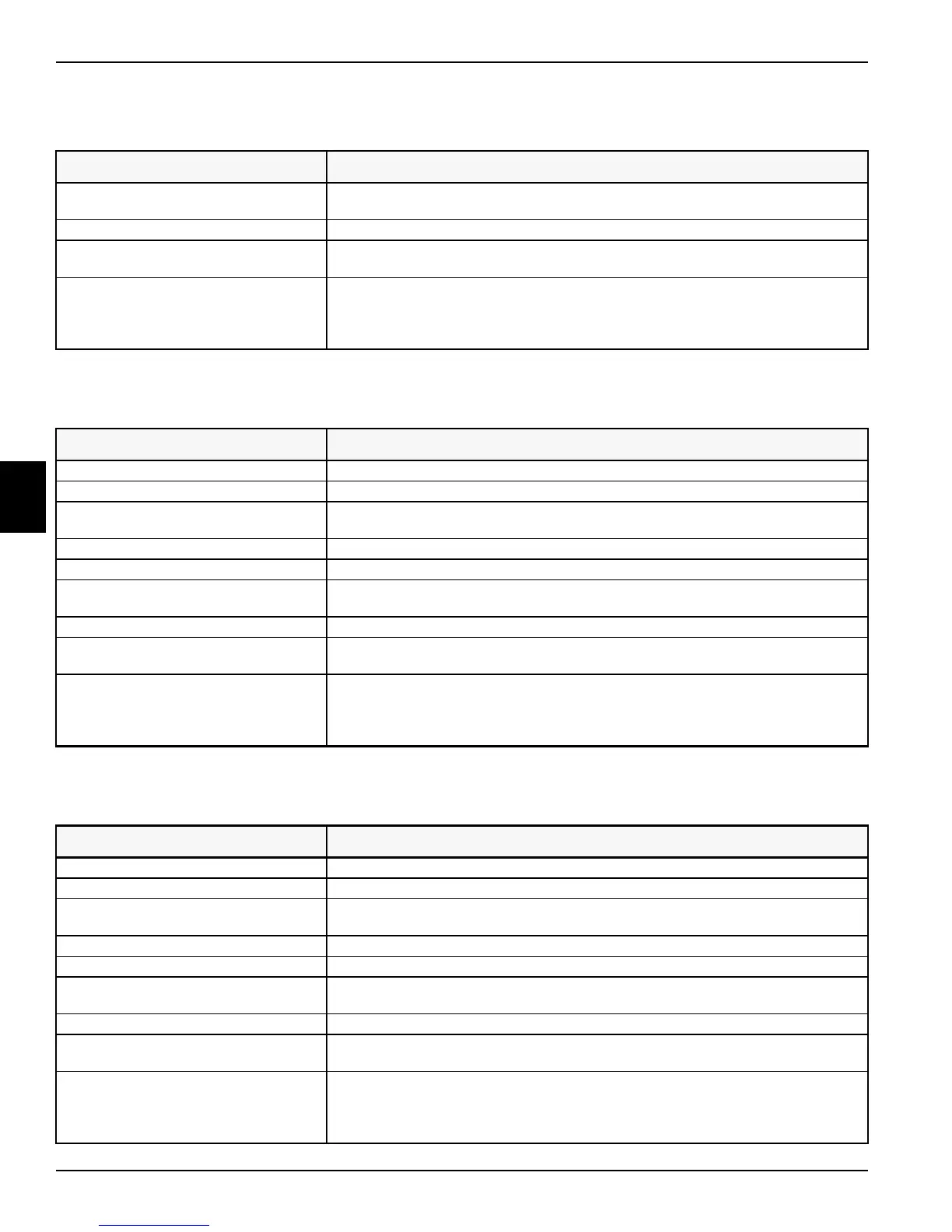

DTC: Right Reel Fault

Reel motor short circuit.

DTC: Left Reel Overcurrent

Reel motor current over 35A for 30 seconds.

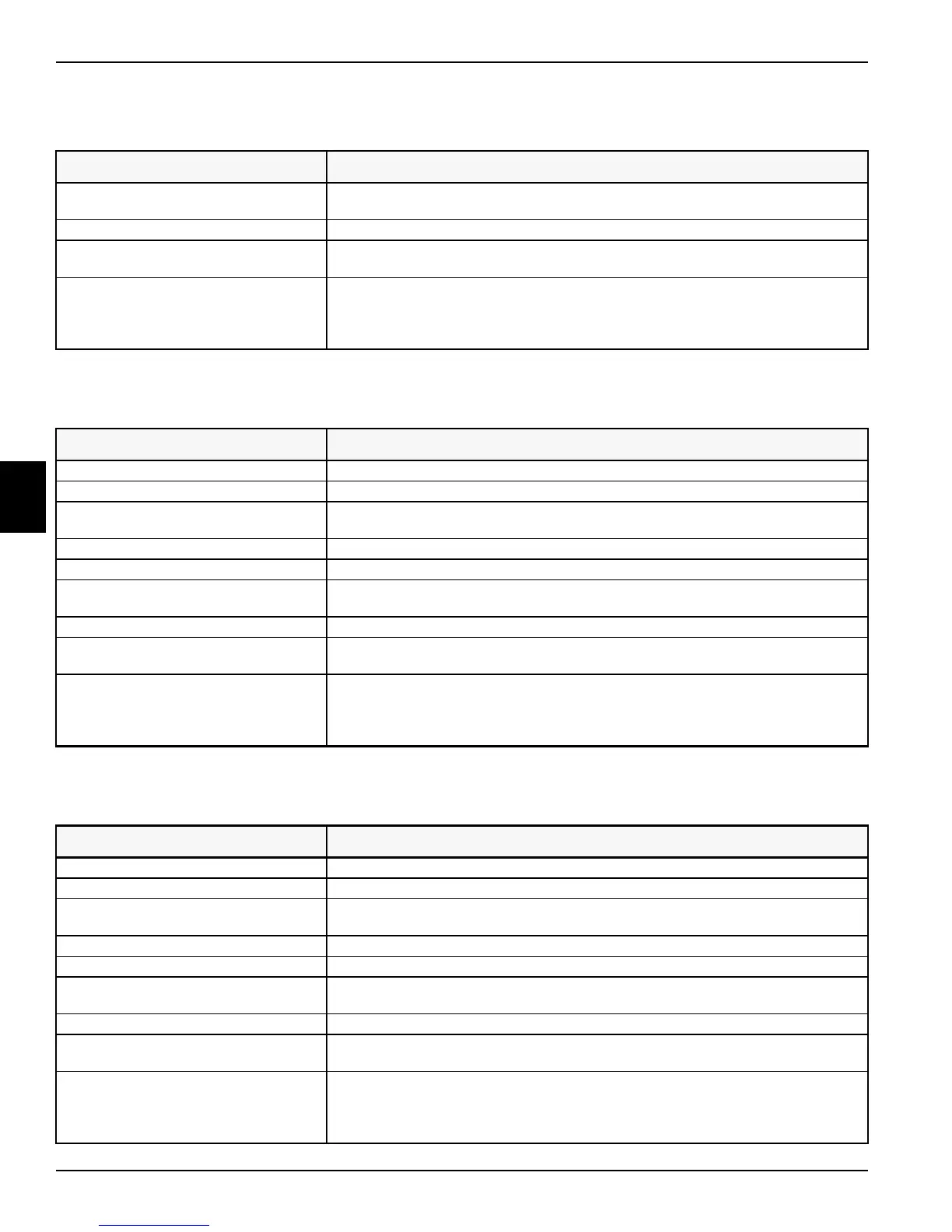

DTC: Center Reel Overcurrent

Reel motor current over 35A for 30 seconds.

Probable Cause Remedy

Jammed cutting unit. Clear cutting unit of all debris. Make sure cutting unit rotates without excessive

resistance.

Faulty connections. Check connections; make sure connections are dry, clean of corrosion and tight.

Shorted wiring harness. Make sure reel motor wiring harness is free of nicks and cuts and not pinched to machine

frame.

Faulty reel motor. Substitute the reel motor with a known good reel motor. If issue is corrected, reinstall old

motor to verify fault returns.

NOTE: If vehicle has split motor, motor and/or motor controller will need to be reinstalled

to verify fault returns.

Probable Cause Remedy

Excessive debris lodged in cutting unit. Clear cutting unit of all debris.

Cutting excessive grass height. Select correct cutting unit configuration.

Excessive mechanical resistance in cutting

unit.

Check bed knife adjustment and reel bearing; make sure the cutting unit rotates without

excessive resistance.

Groomer depth set too aggressive. Adjust groomer depth.

Roller brush misadjusted. Check roller brush adjustment.

Groomer belt or roller brush belt over

tightened.

Check belt adjustment.

Faulty connections. Check connections; make sure connections are dry, clean of corrosion and tight.

Shorted wiring harness. Make sure reel motor wiring harness is free of nicks and cuts and not pinched to machine

frame.

Faulty reel motor. Substitute the reel motor with a known good reel motor. If issue is corrected, reinstall old

motor to verify fault returns.

NOTE: If vehicle has split motor, motor and/or motor controller will need to be reinstalled

to verify fault returns.

Probable Cause Remedy

Excessive debris lodged in cutting unit. Clear cutting unit of all debris.

Cutting excessive grass height. Select correct cutting unit configuration.

Excessive mechanical resistance in cutting

unit.

Check bedknife adjustment and reel bearing; make sure the cutting unit rotates without

excessive resistance.

Groomer depth set too aggressive. Adjust groomer depth.

Roller brush misadjusted. Check roller brush adjustment.

Groomer belt or roller brush belt over

tightened.

Check belt adjustment.

Faulty connections. Check connections; make sure connections are dry, clean of corrosion and tight.

Shorted wiring harness. Make sure reel motor wiring harness is free of nicks and cuts and not pinched to machine

frame.

Faulty reel motor. Substitute the reel motor with a known good reel motor. If issue is corrected, reinstall old

motor to verify fault returns.

NOTE: If vehicle has split motor, motor and/or motor controller will need to be reinstalled

to verify fault returns.

Loading...

Loading...