VSD Series Drives User Manual Powered by Eaton Technology

B-2 For more information visit: www.johnsoncontrols.com LIT-1201828

November 2009

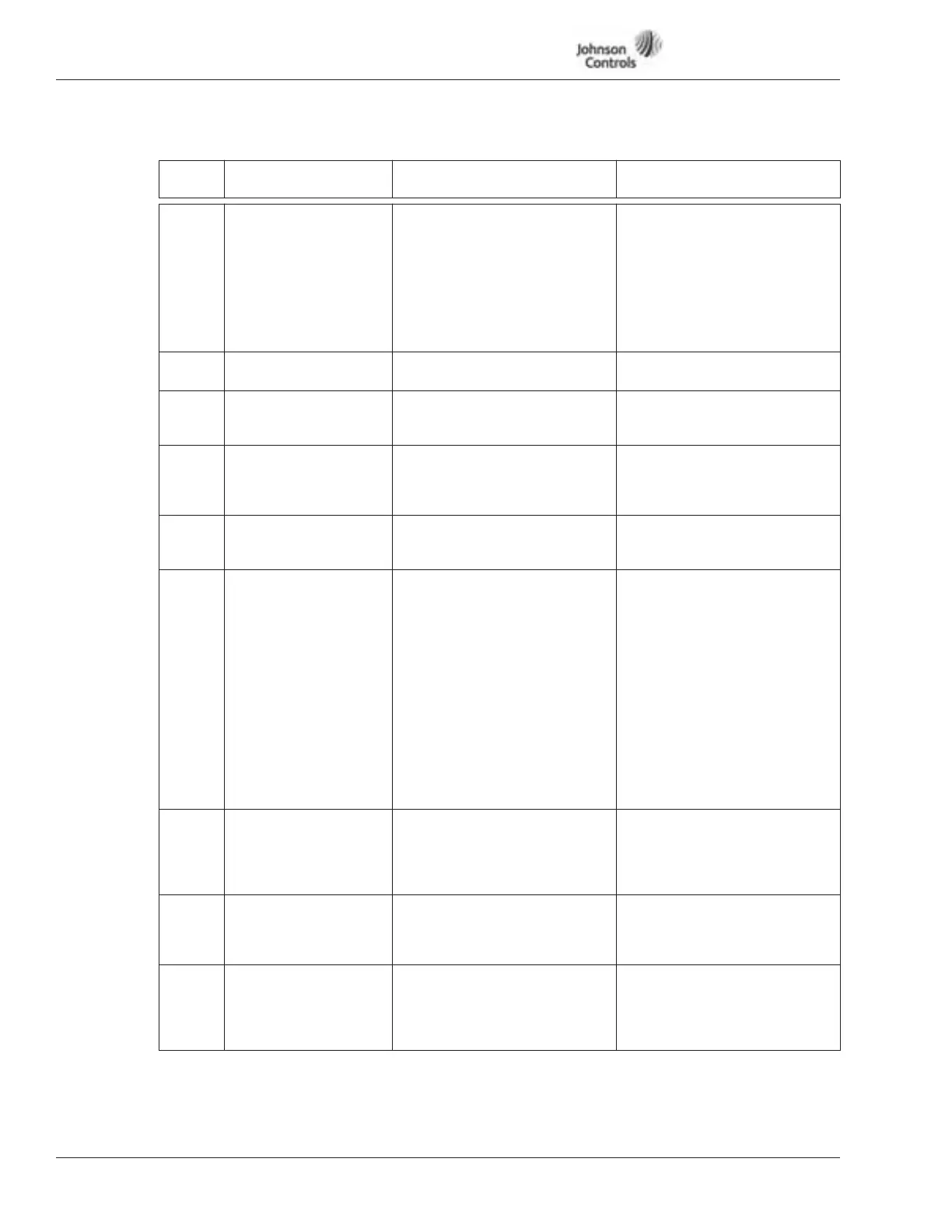

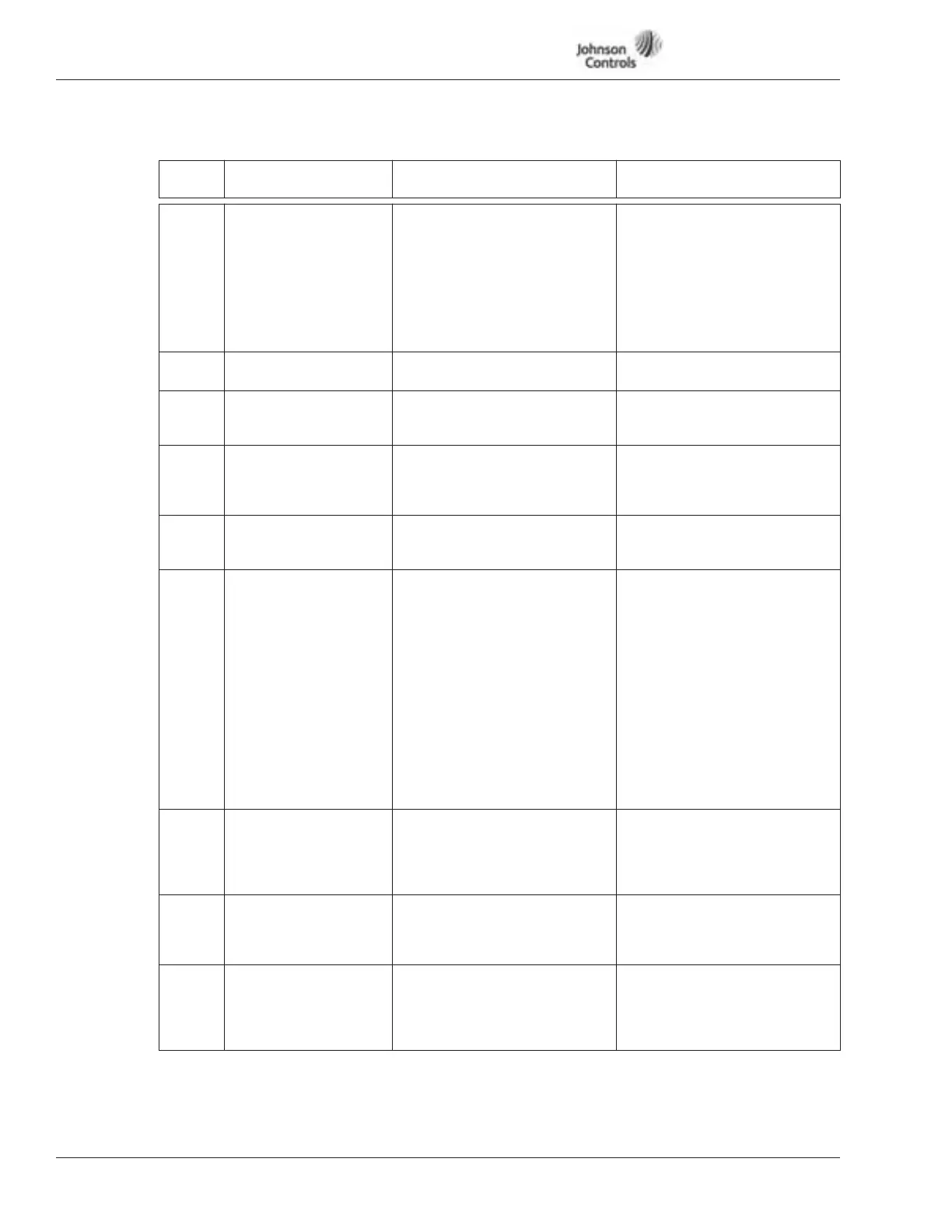

9 Undervoltage DC-link voltage is less than the

minimum safe operating voltage

limit

• most probable cause: too low

a utility supply voltage

• VSD Series internal fault

If there was a supply voltage

loss or dip, reset the fault and

restart the VSD Series drive.

Check the supply voltage. If it

was within specification at the

time of the fault, an internal

failure has occurred. Contact

your Johnson Controls

distributor.

10 Input line supervision Input line phase is low or

missing.

Check the utility supply voltage,

cables and connections.

11 Output phase

supervision

Current sensing indicates that

there is no current in one motor

phase

Check the motor cables,

connections and motor.

12 Brake chopper

supervision

• no brake resistor installed

• brake resistor is broken

• brake chopper failure

Check the brake resistor. If the

resistor is ok, the chopper is

faulty. Contact your Johnson

Controls distributor.

13 VSD Series

undertemperature

Heatsink temperature is under

-10°C

Provide supplemental heating or

relocate the VSD Series drive to

a warmer location.

14 VSD Series

overtemperature

Heatsink temperature is over

90°C.

An overtemperature warning is

issued when the heatsink

temperature exceeds 85°C, a

fault occurs at 90°C. Check for

the correct amount and

unrestricted flow of cooling air.

Check the heatsink for dust or

dirt buildup.

Check the highest ambient

temperature level.

Make sure that the switching

frequency is not set too high in

relation to the ambient

temperature and motor load.

15 Motor stalled • motor or load mechanical

failure

• load too high

• stall parameter settings

incorrect

Check the motor, mechanical

system and load level.

Confirm the stall parameter

settings.

16 Motor overtemperature • motor is overloaded

• motor overheating has been

detected by VSD Series motor

temperature model

Decrease the motor load.

If no motor overload exists,

check the temperature model

parameters.

17 Motor underload • mechanical or load problem

• underload parameter settings

incorrect

Check the motor, check for a

loose belt, broken coupling or

load problems.

Confirm underload parameter

settings.

Table B-1: Fault Codes, continued

Fault

Code Fault Possible Cause Solution

Loading...

Loading...