Chapter 6 Sample preparation guidance

Page 6-10 MAN 0474

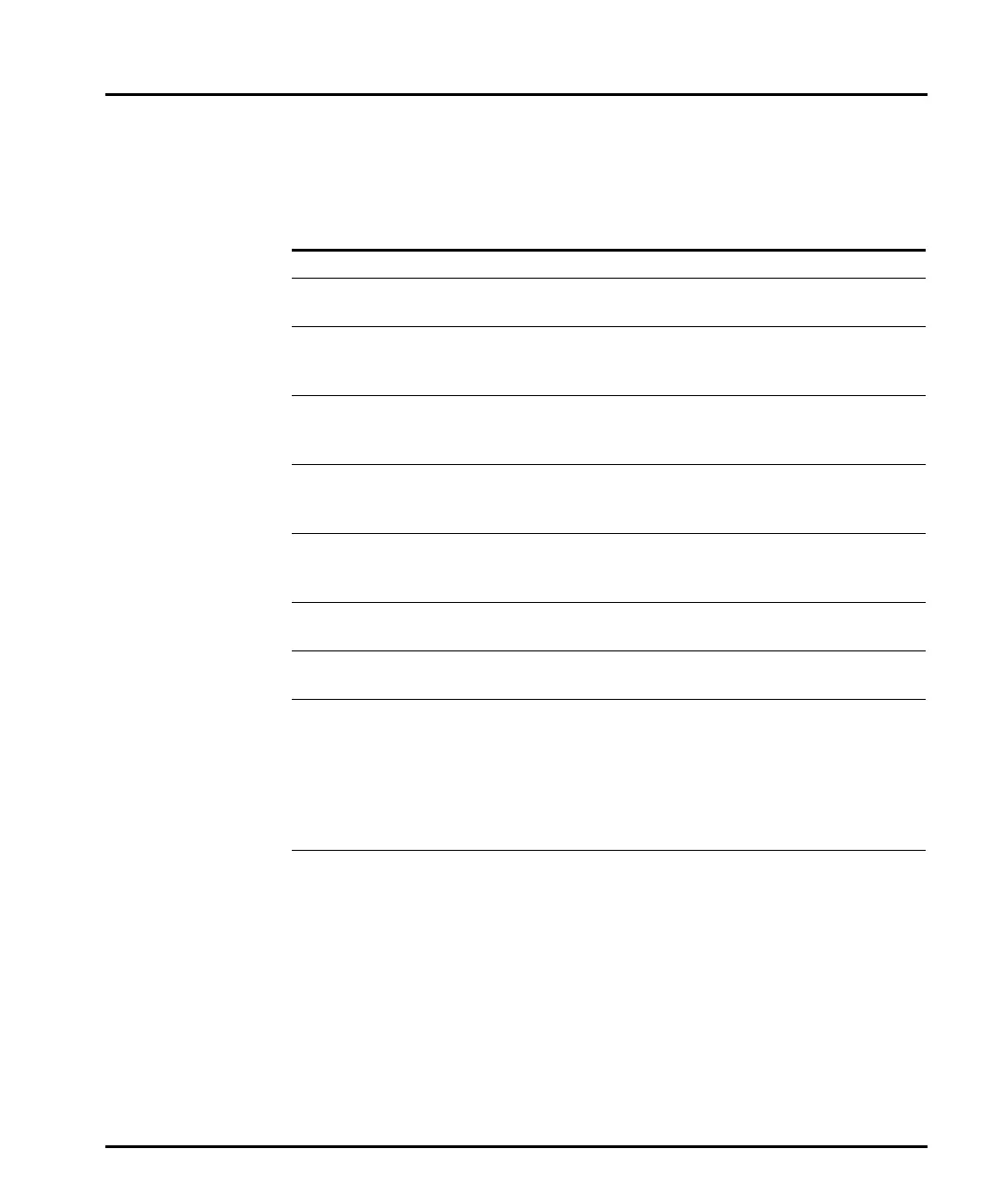

Symptoms of poor sample preparation

Use this table to identify sample dispersion problems:

Problem Symptom Action

Sample dissolving Obscuration decreases. Try another dispersant.

Dispersant contains

impurities

Poor background read-

ings.

Filter the dispersant

before use.

Bubbles within the dis-

persant

Bubbles typically show

as a secondary peak at

100 microns.

Degas the system.

Sample floating on the

surface of the dispersant

Sample seen on the sur-

face of the dispersant in

the tank.

Add surfactant or

admixture.

Sample clumps together Obscuration decreases. Add surfactant or admix-

ture, or use ultrasonic

action.

Sample sinks to the bot-

tom

Obscuration decreases

as the larger particles

settle out.

Increase the pump/stir-

rer speed.

Sample swells in disper-

sant

Obscuration decreases. Try another dispersant.

Particles sticks to the

windows

Rapidly increasing

obscuration.

Use an admixture or sur-

factant.

Condensation on the cell

windows

Rapidly increasing

obscuration.

If (and only if) the disper-

sant is water, add a

quantity of hot (not boil-

ing) water to the tank. If

the obscuration falls,

condensation is the

problem.

Bubbles sticking to win-

dows

Difficulty in obtaining low

background despite

many rinses.

Drain the sampling tank.

The bubbles will burst.

Fill the system carefully

with degassed disper-

sant. In a new system,

adding Decon 90 to the

tank overnight and rins-

ing 7 or 8 times will wet

out the cell surface and

reduce bubble formation.

Loading...

Loading...