Making measurements Chapter 4

Mastersizer 3000 Page 4-3

Note

If, after successfully starting the Mastersizer application software, any of

the functions described in the rest of this section are unavailable to you,

this will be due to your login credentials – contact your system Supervisor

for assistance.

3. Ensure that the status bar indicates that the instrument is connected correctly:

4. If the instrument is not connected correctly (i.e. if anything else is shown in the

status bar), refer to the Software overview chapter for more information on

how to fix this.

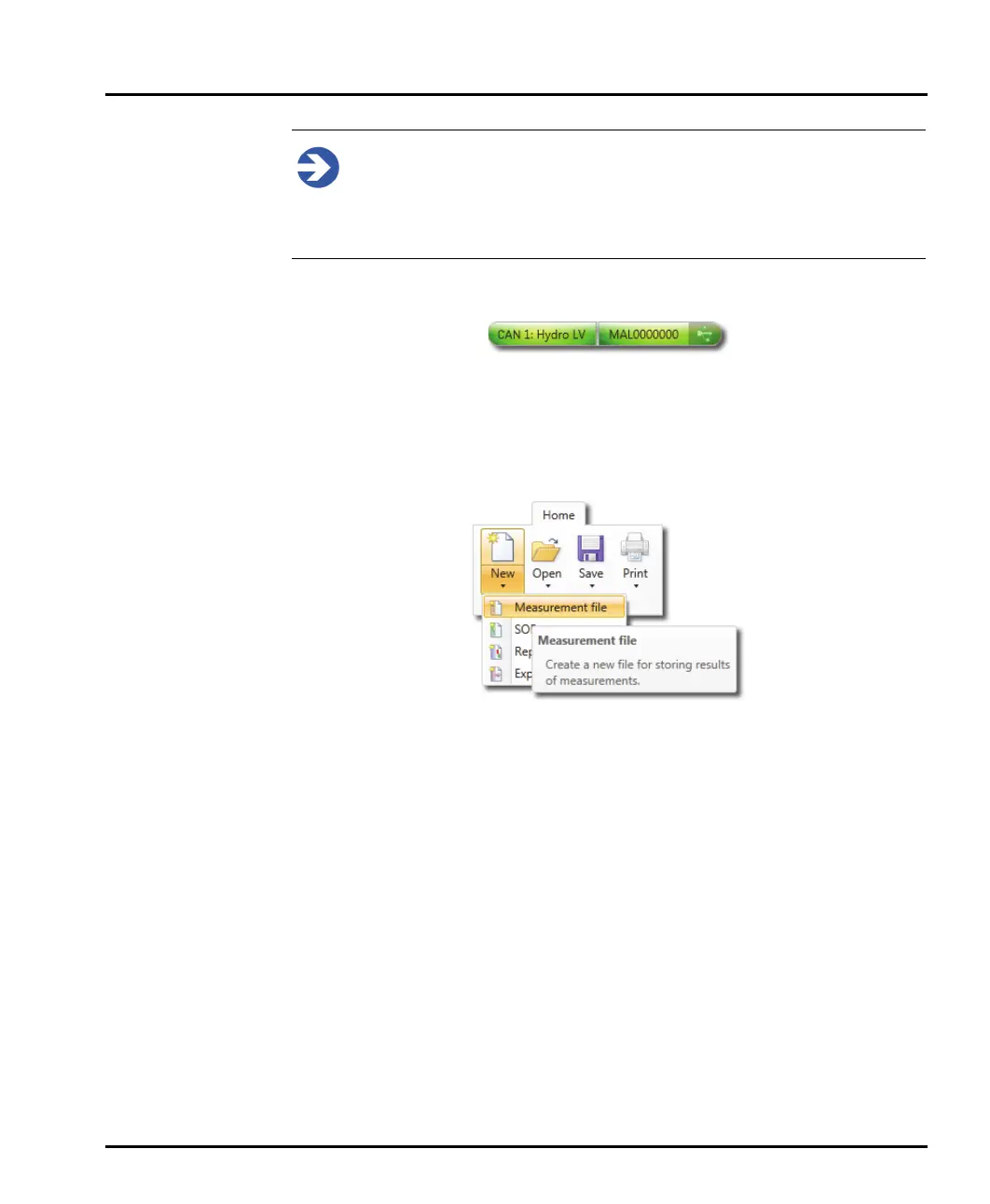

5. Create a new measurement file by selecting New-Measurement File from

Home section of the control ribbon:

Alternatively new measurements can be added to an existing measurement file.

6. Choose Save and then name the measurement file, for example Starter sam-

ple.mmes.

Making SOP measurements

SOPs are predefined measurement sequences that can be used to both automate

and standardise Mastersizer measurements. Widely used in the pharmaceutical

industry to provide traceability, SOPs also provide non-pharmaceutical users with a

reliable means of automating measurements, ensuring that a wide selection of per-

sonnel can obtain consistent results regardless of familiarity with the instrument.

SOPs can control the configuration of the optical unit and the sample dispersion

unit, including the measurement parameters, timings, analysis models and other

specific set-up information. They can also be configured to prompt the operator to

perform specific tasks such as sample preparation steps.

Loading...

Loading...