Manitowoc Published 10-01-2012, Control # 045-08 5-23

777 SERVICE MANUAL HOISTS

5

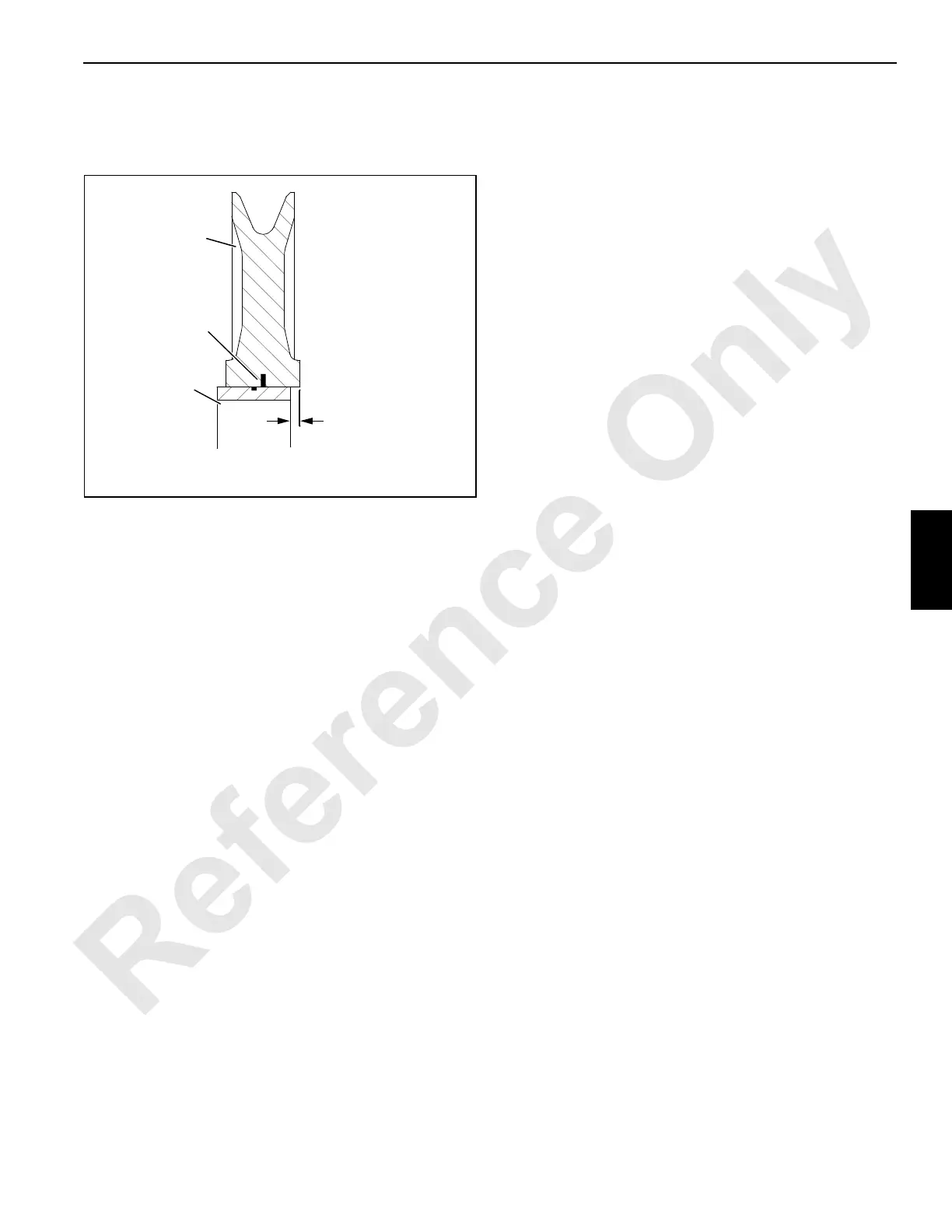

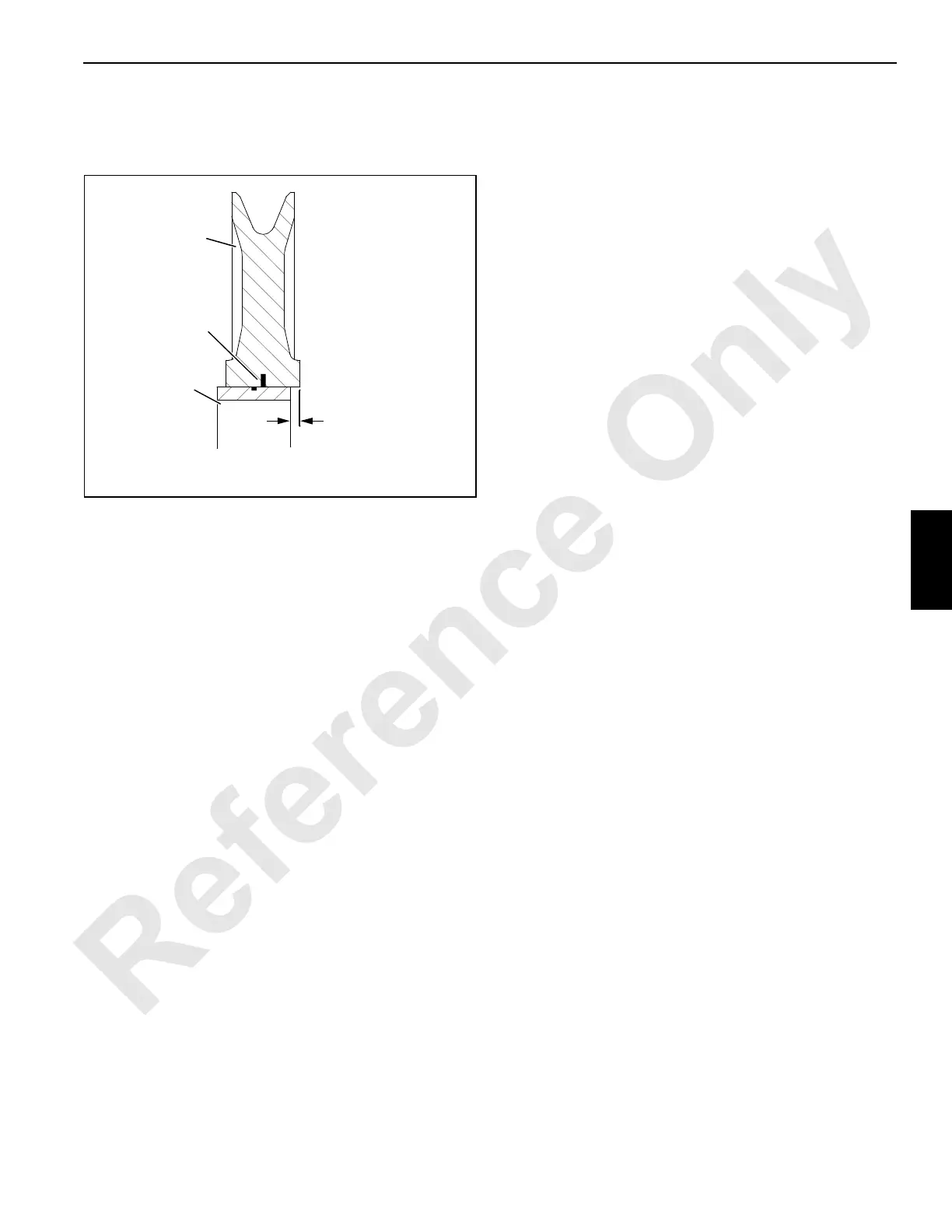

8. Inspect nylon sheaves to verify they have not separated

and “walked off” steel inserts or bearings as shown in

Figure 5-20. Maximum sideways displacement is 1/8 in.

(3 mm). Replace worn or damaged sheave assembly.

9. Make sure sheaves, drums, and rollers are properly

lubricated according to lubrication instructions in

Operator’s Manual.

Many current production sheaves are not equipped with

grease fittings, but are packed with grease at assembly.

Repack the bearings of these sheaves with CraneLUBE

EP #2 grease when the sheaves are overhauled.

Due to application and design variations, it is not

possible to give specific grease repacking intervals or

life expectancy of components.

NOTE: For some sheaves, the seals are an integral part of

the bearing. Therefore, if a seal is damaged during

repacking, the complete bearing may have to be

replaced.

Steel Insert

or Bearing

Nylon

Sheave

Improper

Snap Ring

Engagement

FIGURE 5-20

1/8 in (3 mm)

Maximum Sideways

Displacement

Loading...

Loading...