279

Troubleshooting

11

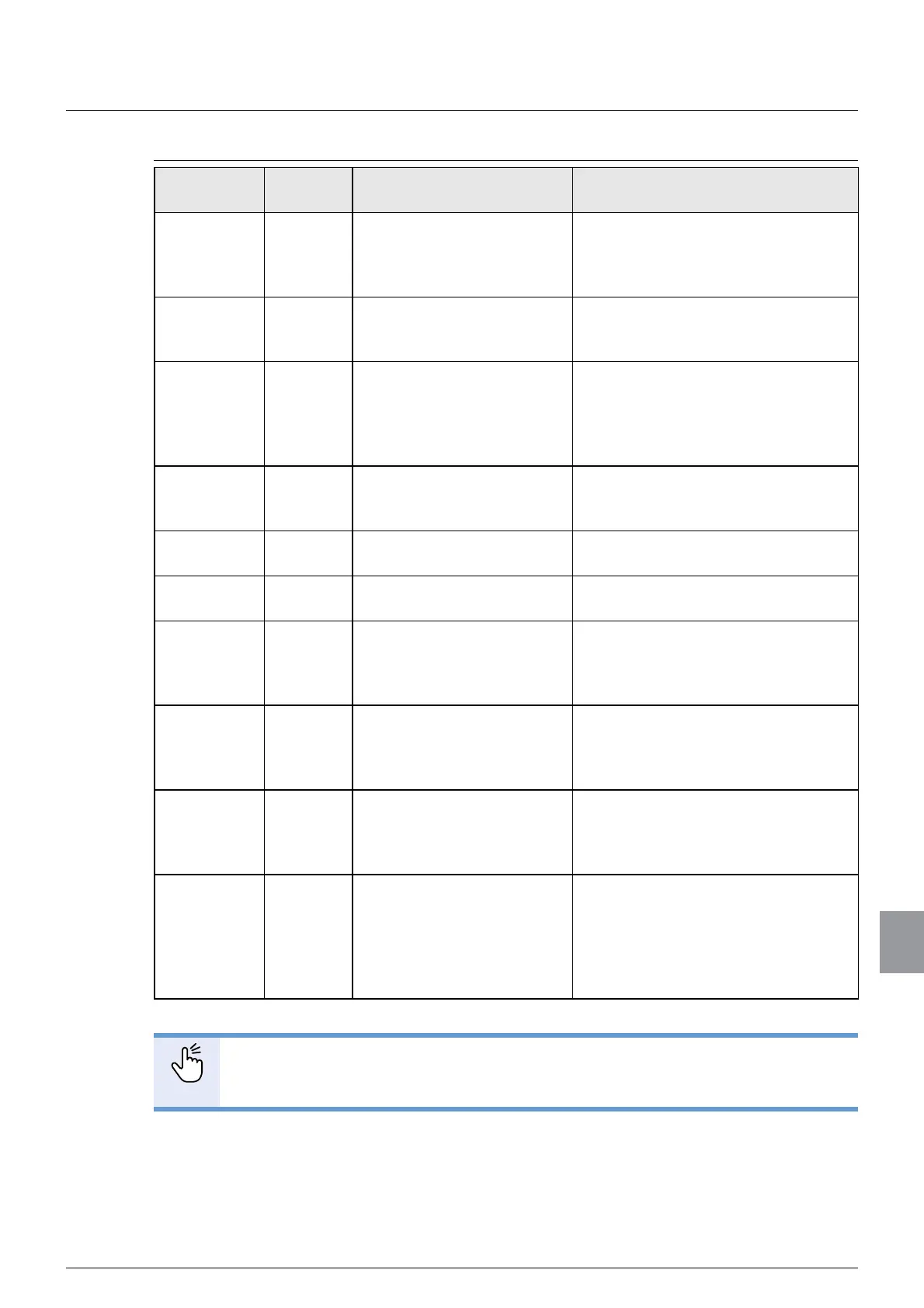

11.2. Error display and buzzer sound

11.2.3. Sequence error display

Error

code

Error

No.

Cause Action

SQ. ERR 0 1 A forced temporary stop has

occurred by inputting the

temporary stop while

weighing.

Check the cause of the temporary

stop to execute a restart.

SQ. ERR 1 2 The safety check conditions

KDYHQRWEHHQVDWLV¿HG

Check the safety check input setting

ĺ8VHRIVDIHW\FKHFN

LQSXW

SQ. ERR 2 3 The capacity has been

LQVXI¿FLHQWHYHQDIWHU

executing supplementary

ÀRZGLVFKDUJH

Change the time and maximum

WLPHVRIWKHVXSSOHPHQWDU\ÀRZWR

H[HFXWHDUHVWDUWĺ%UDQG

VHWWLQJVDQG>0$;7,0(

2)&203(16$7,21@VHWWLQJV

SQ. ERR 3 4 The magnitude relation of

the setting values has been

contradictory.

Check the setting vales to solve the

FRQWUDGLFWLRQĺ%UDQG

VHWWLQJV

SQ. ERR 4 5 7KHÀRZWLPHKDVH[FHHGHG

the the time limit.

Check the batch gate for clogging.

SQ. ERR 5 6 The discharge time has

exceeded the time limit.

Check the discharge gate for

clogging.

SQ. ERR 6 7 The gross value is less than

WKH¿QDOYDOXHDWWKHWLPHRI

weighing in discharge

mode.

Add material to the brand hopper.

SQ. ERR 7 8 The net value is more than

WKHYDOXHRI¿QDOYDOXH

IUHHIDOOYDOXHDWWKHVWDUWRI

weighing.

Empty the container.

SQ. ERR 8 9 During weighing in nozzle

control mode, the nozzle

has come into contact with

the container.

Check the nozzle position.

SQ. ERR 9 10 The container was not

placed at the weighing

device when weighing was

started with [START ABOVE

=(52%$1'@VHWWR

[VALID].

Place the container at the weighing

device.

POINT

7RUHOHDVHDVHTXHQFHHUURUWDS>(55255(6(7@NH\ZKLFKLVORFDWHGDWWKH

screen's upper left.

Loading...

Loading...