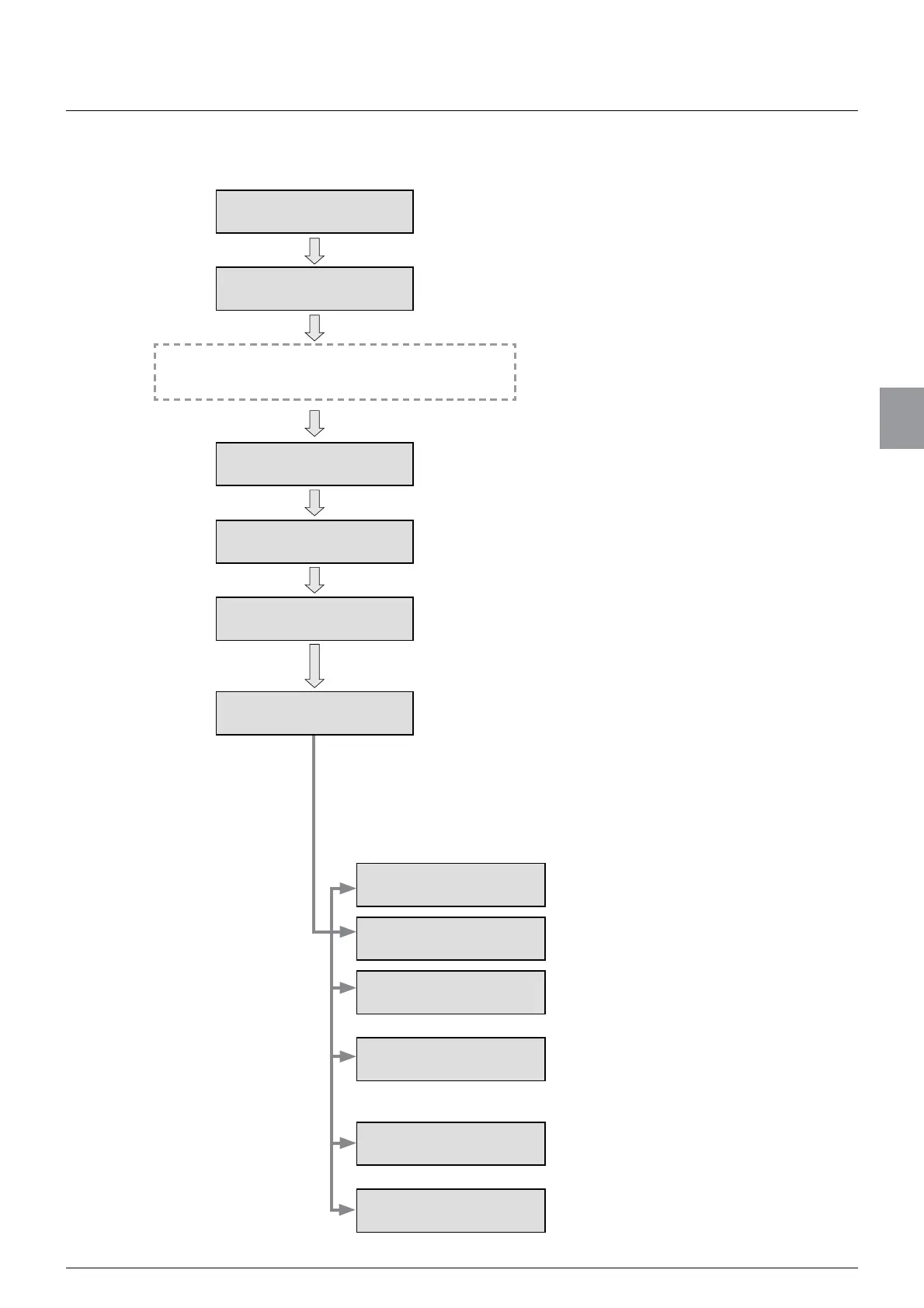

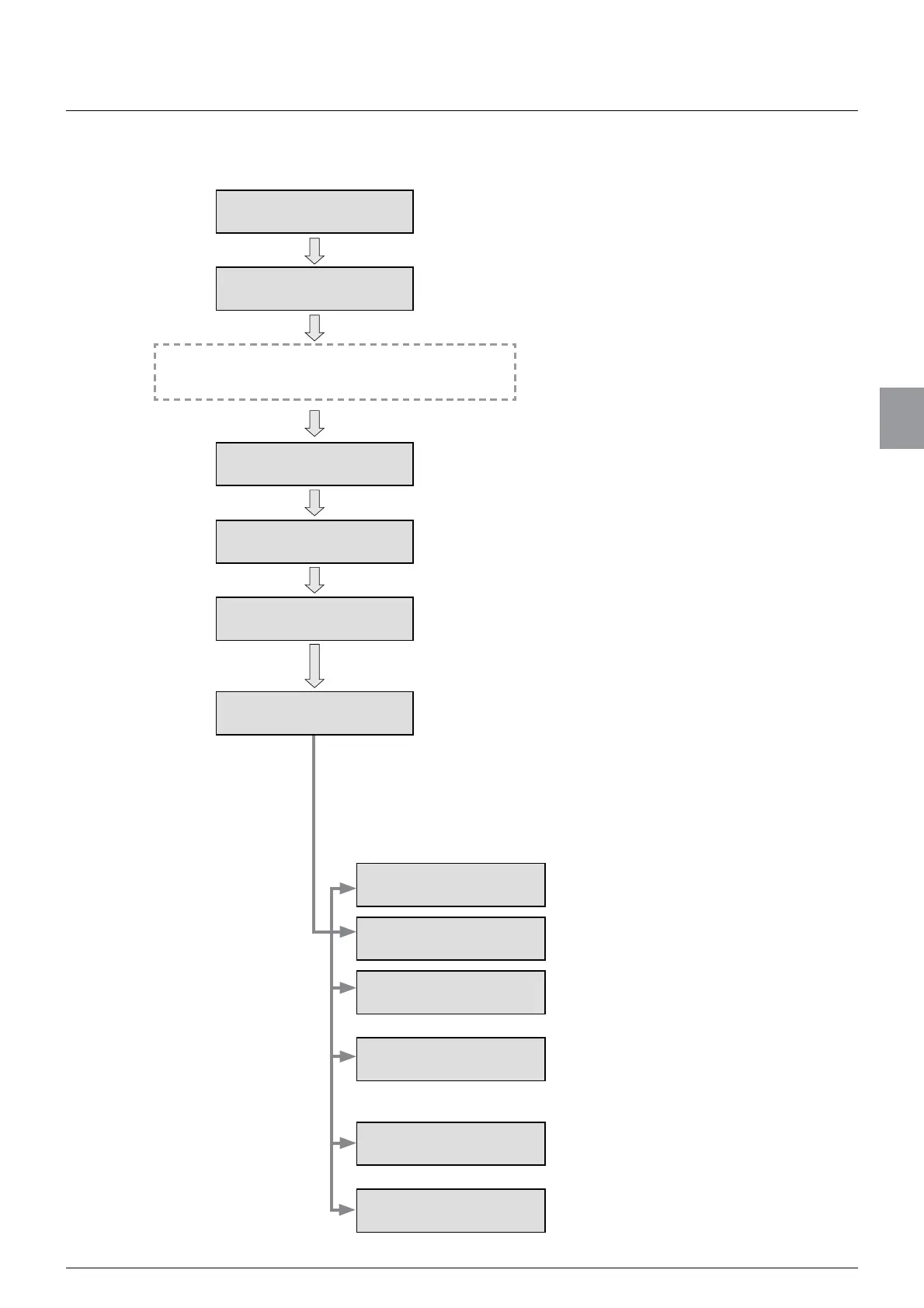

4.2.Flow of calibration

27

4

Calibration

4.2. Flow of calibration

To stabilize CSD-912B and the weighing device

(load cell), energize them for about ten minutes.

Display Calibration

screen

Display Calibration screen from Menu screen.

Set [BRIDGE POWER

SUPPLY]

Set the voltage (DC) to apply to the load cell.

Set [DIVISION]

(minimum scale interval)

Set the minimum unit of weighing values.

Set [WEIGHING

CAPACITY]

Set the maximum load that can be measured by the

weighing device (load cell).

[ZERO ADJUSTMENT]

Register the zero point of the weighing device (load cell).

Read the output value of the load cell with no load on the

weighing device (initial state including the weight of an

empty container), or set the output voltage value of the

load cell.

Register the span point of the weighing device (load cell).

Read the output value of the load cell with a weight on the

weighing device, or set the value that is calculated by

deducting the output voltage value at the zero point from

the output voltage value at the load cell’s span point.

Fine adjustment of zero

point

Finely adjust the zero point.

Fine adjustment of span

point

Finely adjust the span point.

[DIGITAL LINEARISE]

Correct the measurement errors between

the zero point and the span point.

[PITCH

CONFIRMATION SET]

Register the A/D count value of an

arbitrary load as the pitch point to

FRPSOHWHFDOLEUDWLRQDQGYHUL¿FDWLRQDW

the same time.

Gravitational acceleration

compensation

Correct span errors if the place to use

CSD-912B is different from where

calibration has been performed.

Calibration lock

Lock calibration results to prevent them

from being changed.

,I&6'%UHTXLUHVDGMXVWPHQWFRQ¿JXUHWKHIROORZLQJ

VHWWLQJVDVQHHGHGĺ$GMXVWPHQWDIWHUFDOLEUDWLRQ

[SPAN ADJUSTMENT]

Loading...

Loading...