1. Precautions for inspections

・

When measuring the insulation between the power line and motor line, always disconnect the

wires connected to the inverter first. Do not perform a megger test on the control circuit.

・

The inverter is mainly configured of semiconductor elements. So, daily inspections must be

carried out to prevent the effect of the working environment such as the temperature, humidity,

dust and vibration, to prevent problems that occur due to the passage of part usage and part life.

The standard replacement term that apply when the inverter is used in a general environment

(ambient average annual temperature 30℃, load rate of 80% or less, and 12 working hours or

less a day) are given in the following table.

2. Inspection Items

1) Daily inspection: Check that the inverter is operating as intended.

Check the input and output voltages of the inverter during operation

using a multimeter.

2) Periodic inspection: Check all locations where inspection can only be performed when the

inverter is stopped and where periodic inspection is required.

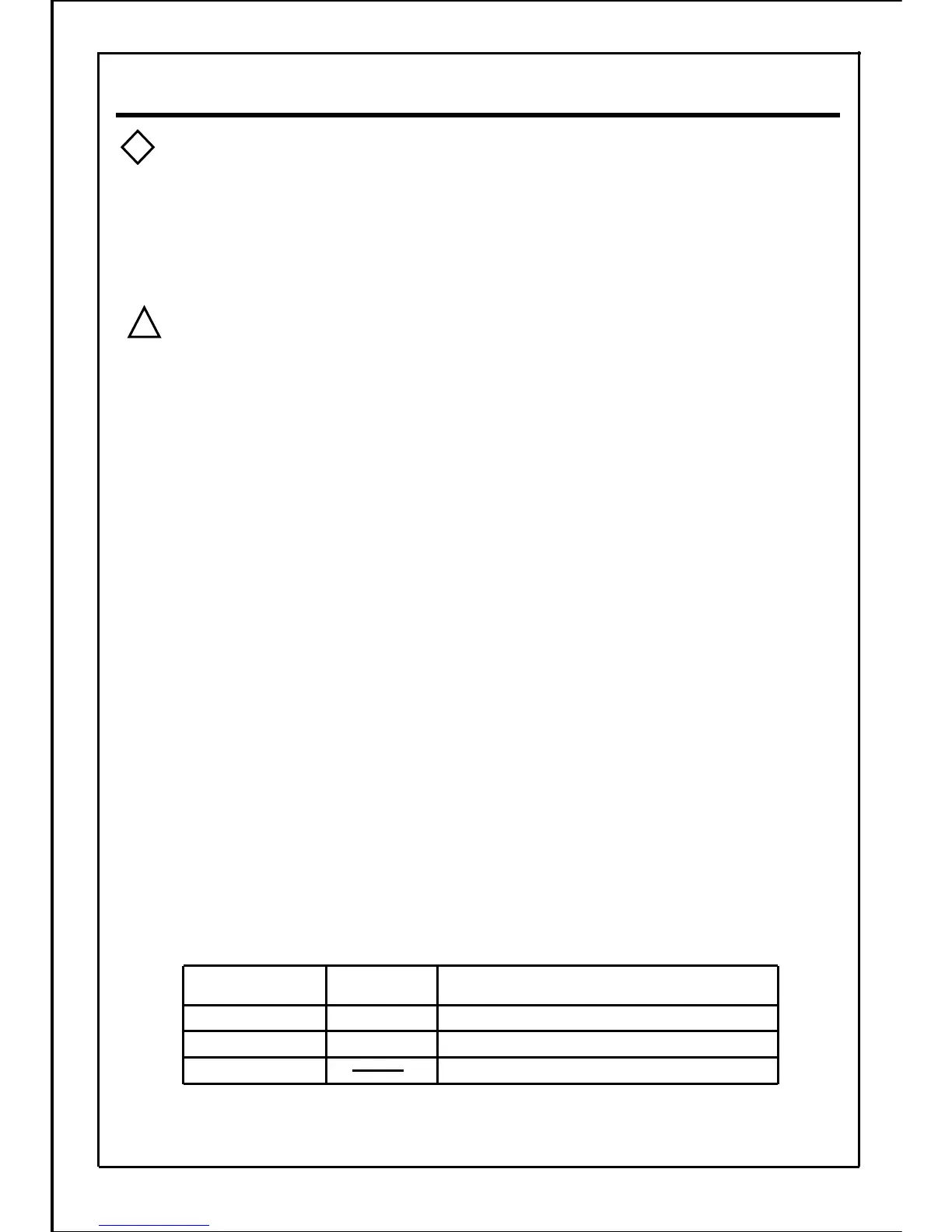

3. Parts Replacement

Wear fault (lifetime)…The lifetime is greatly dependent on the installation conditions.

1) For example: The lifetime of a relay depends on the wear condition of its contact surfaces.

The contact current and load inductance are major factors.

2) The capacitor inside the inverter is used mainly as a smoothing filter and its lifetime varies

greatly with temperature as internal chemical reactions take place. Generally, when the

temperature of the aluminum electrolytic capacitor increases by 10℃, the life is halved.

Thus, the temperature determines the inverter life span.

If the inverter is used at high temperatures, the aluminum electrolytic capacitor could wear out

before the other parts. In this case, the capacitor must be replaced to extend the inverter's life.

Part name

Cooling fan

Smoothing capacitor

Relays

Standard

replacement

2 or 3 years

5 years

Replacement procedure

Replace with a new part

Investigate and replace with new part if necessary.

Investigate and replace with new part if necessary.

◆

Contact us if you need part replacement or repairs.

15. Maintenance and Inspection

!

Caution

Note

!

● Wait at least 5 minutes after turning the input power OFF before starting maintenance

and inspection.

Failure to do so could lead to electric shock.

●

Maintenance, inspection and part replacement must be done by qualified persons.

[Remove all metal personal belongings (watches, bracelets, etc.) before starting work.]

(Use tools treated with insulation.)

Failure to do so could lead to electric shock or injury.

● Have electric company periodically tighten the terminal screws.

Loosening of the terminal screws could lead to overheating or fire.

200

Loading...

Loading...