O

rder No.

35 MHz: F 8042

40 MHz: F 8043

41 MHz: F 8044

FX-30

13

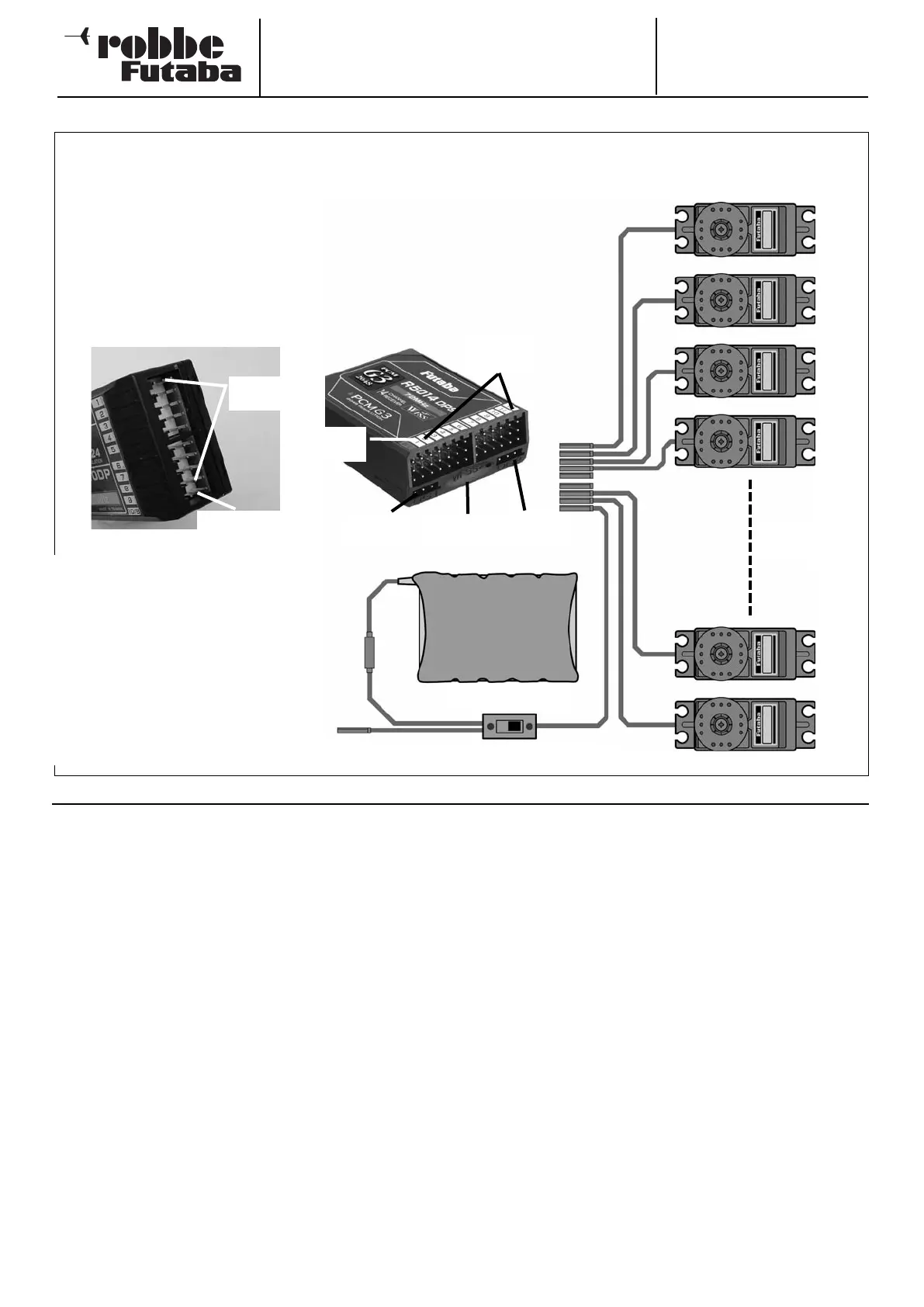

5.1 CONNECTING SERVOS - PCM 1024 AND PCM 2048 (G3)

Charge socket On / Off switch

Receiver battery

Servos

1 … 10 / 12

10/B = battery,

or channel 10

Channels

1

… 9

Connecting servos and power supply:

R 1410 DP receiver

S

ocket: 10/B = receiver battery or servo for 10th channel, using Y-lead if necessary

Outputs 1 … 9: 1 … 9 proportional channels for servos

Note:

If the number of powerful analogue or

digital servos connected to the recei-

ver is high, the standard switch har-

ness supplied in the set will not be

capable of handling the heavy cur-

rents which will flow. In such systems

it is necessary to use a suitable high-

current power supply (usually known

as a Power battery backer) to supply

the servos and receiver. Ask at a spe-

cialist model shop for details.

NEW SYSTEM FOR FUNCTION SEQUENCE

For the PCM-G3 system the second aileron output has been

shifted to output 5, in order to maintain compatibility with

small five-channel and six-channel receivers; the increased

number of channels has also necessitated this change. This

means that the receiver channel sequence is not the same as

that of the PCM 1024 system.

To maintain compatibility with the PCM-1024 system it is pos-

sible to select any function sequence you like; this is accom-

plished in the “Function” menu.

Note:

If you need to change the function sequence when using the

PCM-G3 system, please ensure that associated functions are

allocated together within the channel groups 1 … 6 or 7 … 12.

Do not assign paired functions to channels 6 and 7, as this

could result in different servo transit times.

The transmitter employs a new, graphical method of selecting

the model type as basis for the mixer functions and transmit-

ter control arrangement (stick mode), and this automatically

generates a suggested configuration for the selected model

type. We recommend that you keep to this set-up if possible,

so that you are always using a standard configuration.

The “Function” menu clearly shows the output to which the

corresponding servo is connected, and which transmitter con-

trol is used to operate it. Where a single function operates two

or more servos, the corresponding transmitter controls are

configured accordingly.

Within an individual model type the configuration varies little,

although the number of channels in use may increase if the

number of wing flaps and other control surfaces is higher than

usual.

The situation is different when you switch from one model type

to another. For example, if you change the model type from a

normal tail to a tail layout with two elevator servos (Ailvator),

the sequence of functions is necessarily different.

The same also applies, of course, to model gliders (powered

and unpowered), and for flying wing models with and without

winglets.

The following pages contain comprehensive tables and sket-

ches which clearly show the servo connection sequence,

arranged according to the different model types which are

managed by the software.

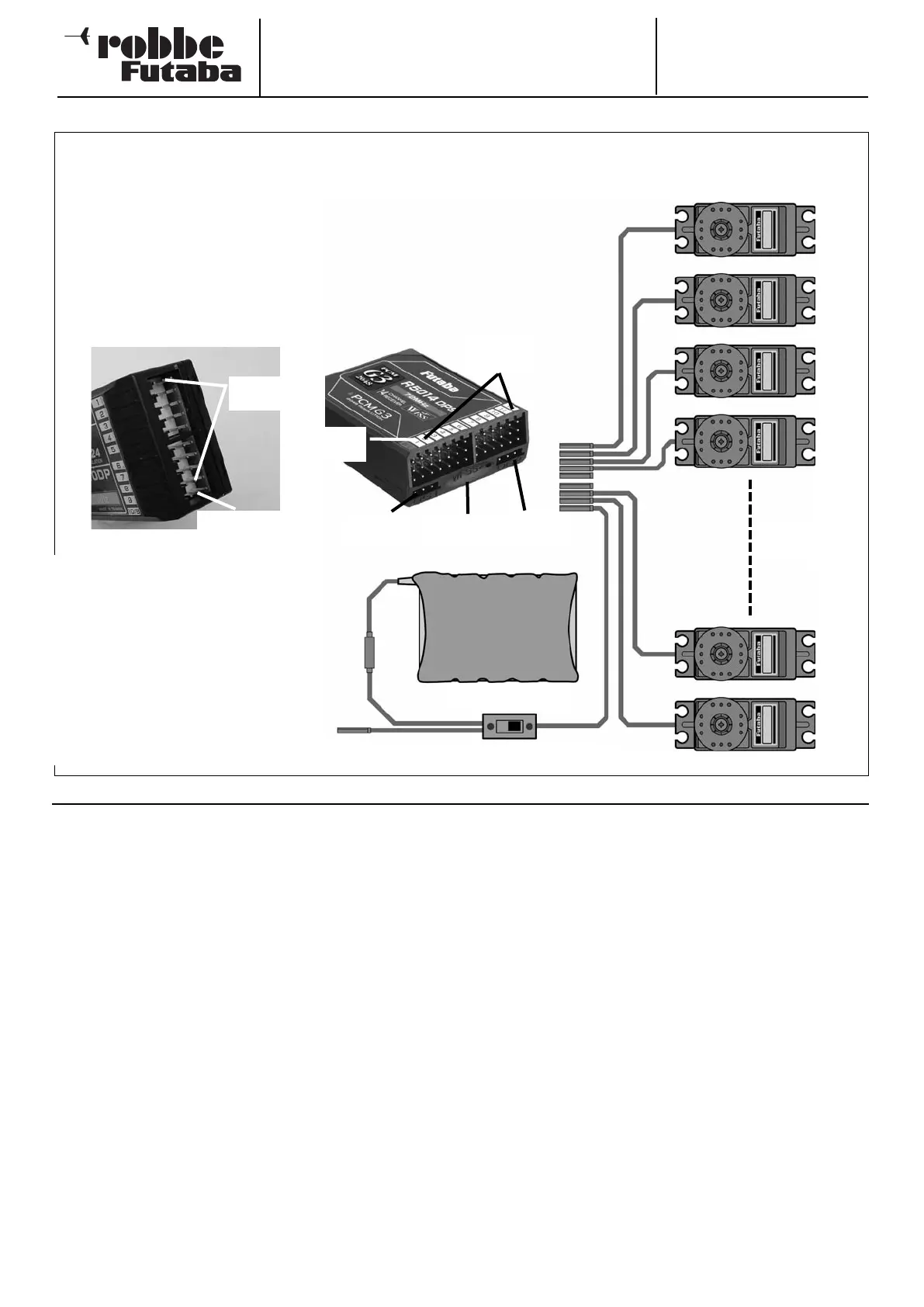

R 5114 DPS receiver

Socket: B/C = receiver battery or DSC lead

Outputs 1 … 12: 1 … 12 proportional channels for servos

Outputs DG1 and DG2: Switched channels 13 and 14

Monitor LED: Indicates the status of the wireless spot frequency transmission

Channels

1 … 12

Channel

DG2 = 14

Channel

DG1 = 13

Monitor

LED

Battery /

DSC

Loading...

Loading...