Order No.

35 MHz: F 8042

40 MHz: F 8043

41 MHz: F 8044

FX-30

• Trim Mode

Once you have marked and confirmed this field, you can

set any of the following trim modes by turning the ‘3-D hot-

key’.

Normal = Normal trim type; the trim range is symmetrical

around the servo centre-point. The selected (fixed) trim

range is offset around the centre, which causes changes to

the end-point values.

A

TL = Asymmetrical trim type; the trim value alters only at

one end of the transmitter control range. This is usually

employed for the throttle function, so that you can fine-trim

the idle without affecting the full-throttle position.

CTRM = Centre trim; this trim function also affects the

centre range of the transmitter control, but has no effect on

the end-points. Since the end-points are fixed, the trim tra-

vels change (i.e. become asymmetrical) if you alter the trim

value.

• Global or Separate mode

The ‘Global’ and ‘Separate’ fields determine whether the

trim controls are to be the same for this function in all flight

modes (Global). If you change this function to ‘Separate’,

the trim control for this function can be different for each

flight mode. Turn the ‘3-D hot-key’ to left or right to chan-

ge this setting. The display changes when you operate the

selected flight mode change-over switch.

Note:

Changing the trim from Global to Separate makes it possible

to alter the configuration of various trim controls to suit each

flight mode; it also enables the user to set and store different

trim values for each flight mode.

Typical applications:

1. Different trim controls for each flight mode

In the Normal flight mode the trim controls T1 + T4 are

assigned to control functions J1 + J4. In the ‘Aerobatics’

flight mode the trim controls T1 + T4 are assigned in rever-

se (cross-trims). This makes it possible to control the func-

tion with the one hand, and adjust the trim for the same

function with the other hand.

2. Different trim values for each flight mode

Model helicopters: it can be highly advantageous if the dif-

ferent trim values for the static flight mode ‘Hover’ and the

dynamic flight mode ‘Aerobatics’ can be set and stored

separately.

VIRTUAL CHANNELS: this set-up menu is used to configure

the virtual functions VC-1 … VC-4. The term ‘virtual function’

is used to describe functions which use other channels as

‘double functions’, i.e. they do not have their own servo chan-

nels.

A virtual channel is a separate second control curve with which

a transmitter control affects the servo output.

Examples of this are the Crow (Butterfly) function, which con-

trols the aileron and flap servos, or the elevator function of a

flying wing model, where the ailerons have a dual function,

‘doubling up’ as elevators.

The servo sequence tables (Sections 5.1 to 5.4) on pages 14

to 17 include the virtual functions.

SWITCHED CHANNELS 9 + 10 AND 13 + 14

The switched channels 9 + 10 in PCM 1024 mode, and 13 +

14 in PCM G3 mode, are operated using the transmitter con-

trols DG1 + DG2.

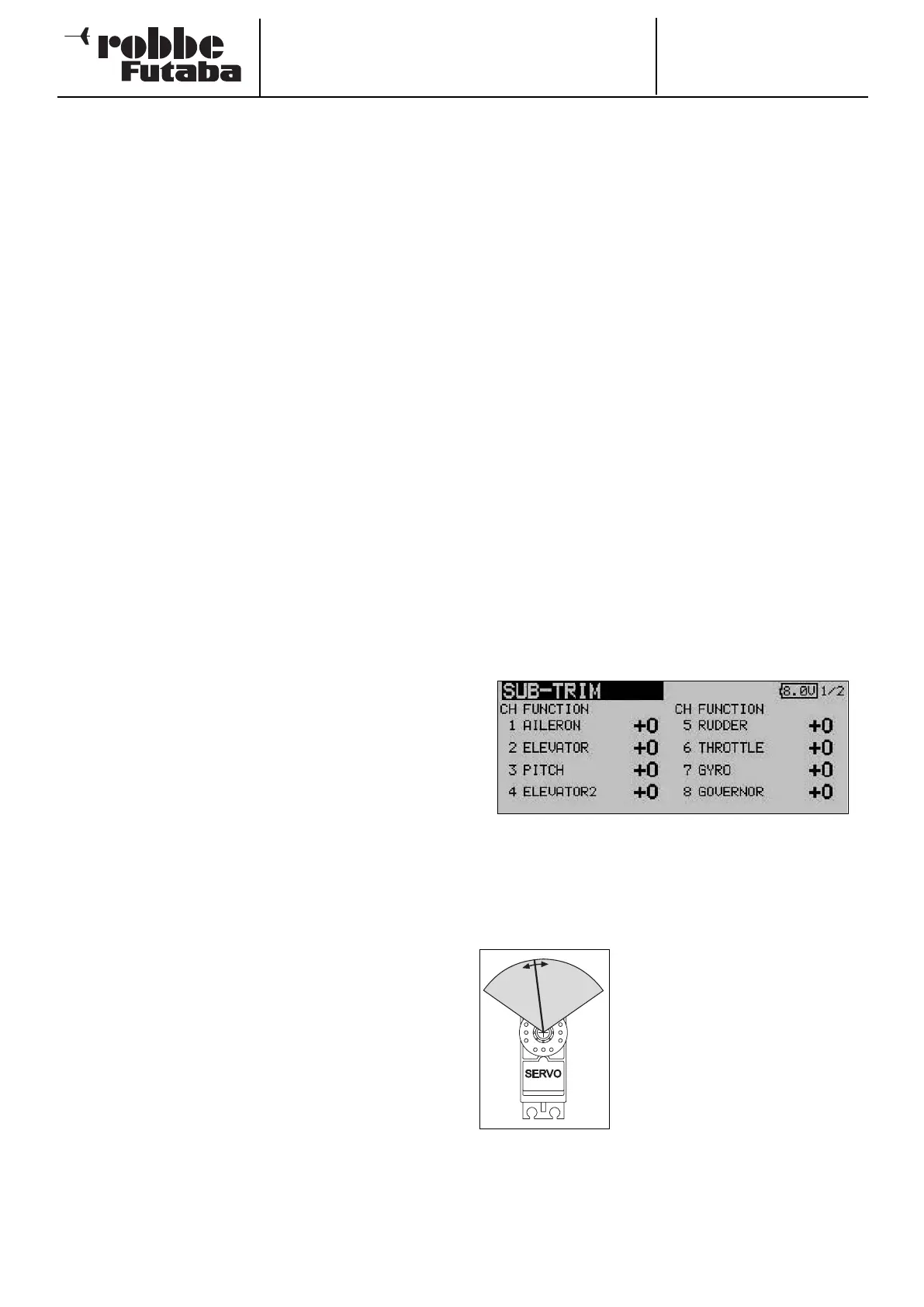

12.6 SERVO CENTRE OFFSET

When you install the servos in a model, it is always best to

position them in such a way that the servo output arm is in the

neutral position when the associated trim control on the trans-

mitter is also at centre.

Sometimes the design of the model makes this impossible,

and in other cases the neutral position is non-standard due to

the use of different makes of servo. In such instances this

function can be used to bring the servos of all channels to the

exact neutral position.

This option should only be used to correct minor discrepan-

cies, as it inevitably affects servo travel, which may become

r

estricted and asymmetrical.

We recommend this procedure:

After establishing the correct trim positions through test-flying,

the first step should be to adjust the position of the servo out-

put arms as accurately as possible, and adjust the control sur-

face linkages to the correct mechanical trim settings. At this

stage the trim memory and the settings in this menu should be

left at 0%. Once you have made these adjustments as accura-

tely as possible, you should use this menu to fine-tune the

servo neutral positions to exact centre.

Note:

Always determine the correct direction of servo rotation (servo

reverse) before adjusting the servo centre offset; see page 33.

Use the 3-D hot-key to mark the ‘Servo centre’ function in the

Base menu, and confirm your choice using EDIT.

This menu has a second level (page) for channels 9 to 12; the

page number on the right-hand side indicates this.

The servo positions are always displayed as a value and as a

%-value.

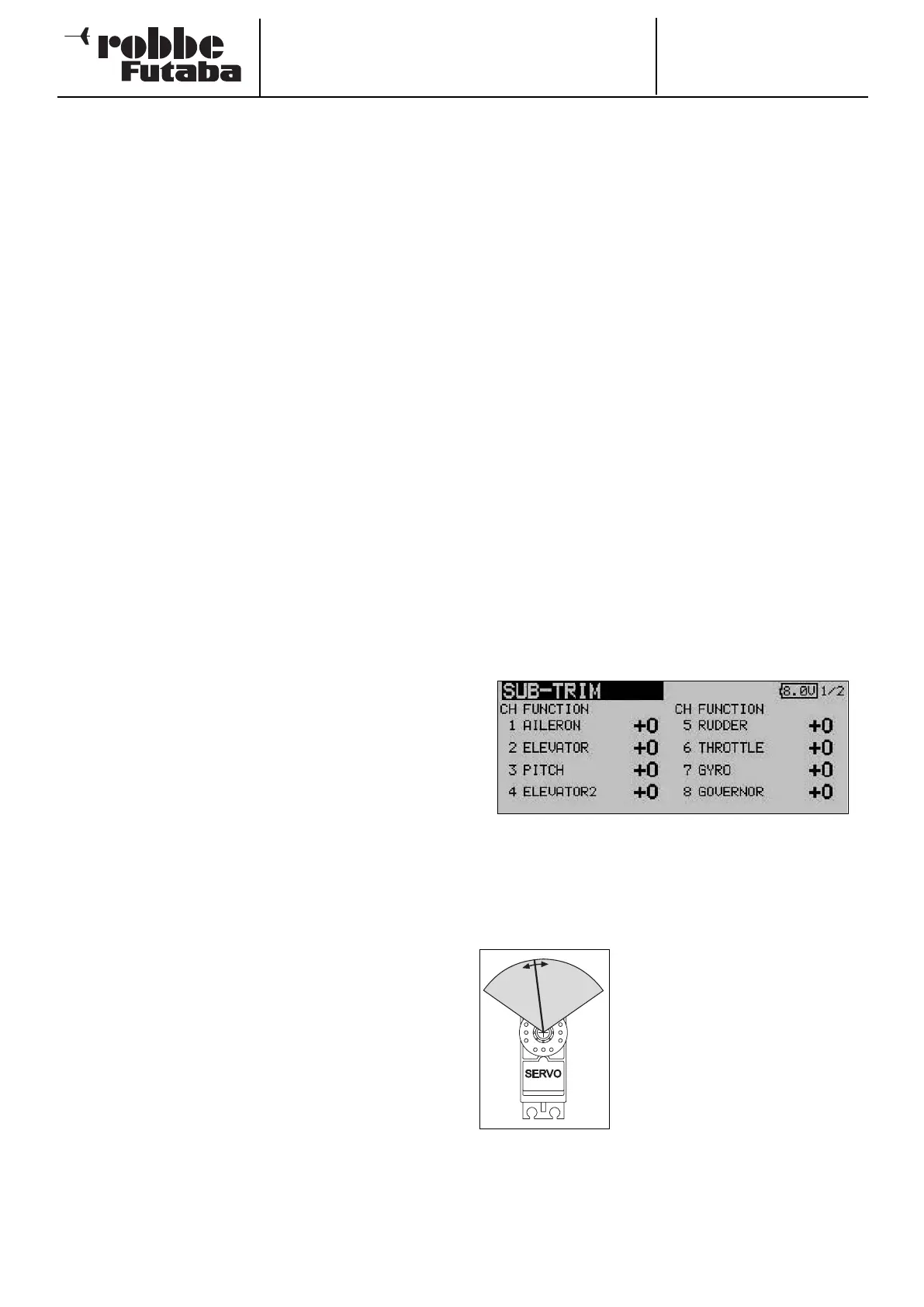

To change a setting the appropriate

channel must first be marked with the

cursor. Select the correct channel,

then adjust the trim increments by

rotating the 3-D hot-key. The adjust-

ment range is -240 increments to +240

increments, corresponding to around

+/- 20° of servo travel. The default set-

ting is 0 increments.

You can change any active setting back to the default value (0

increments) by holding the 3-D hot-key pressed in for at least

one second.

32

Loading...

Loading...