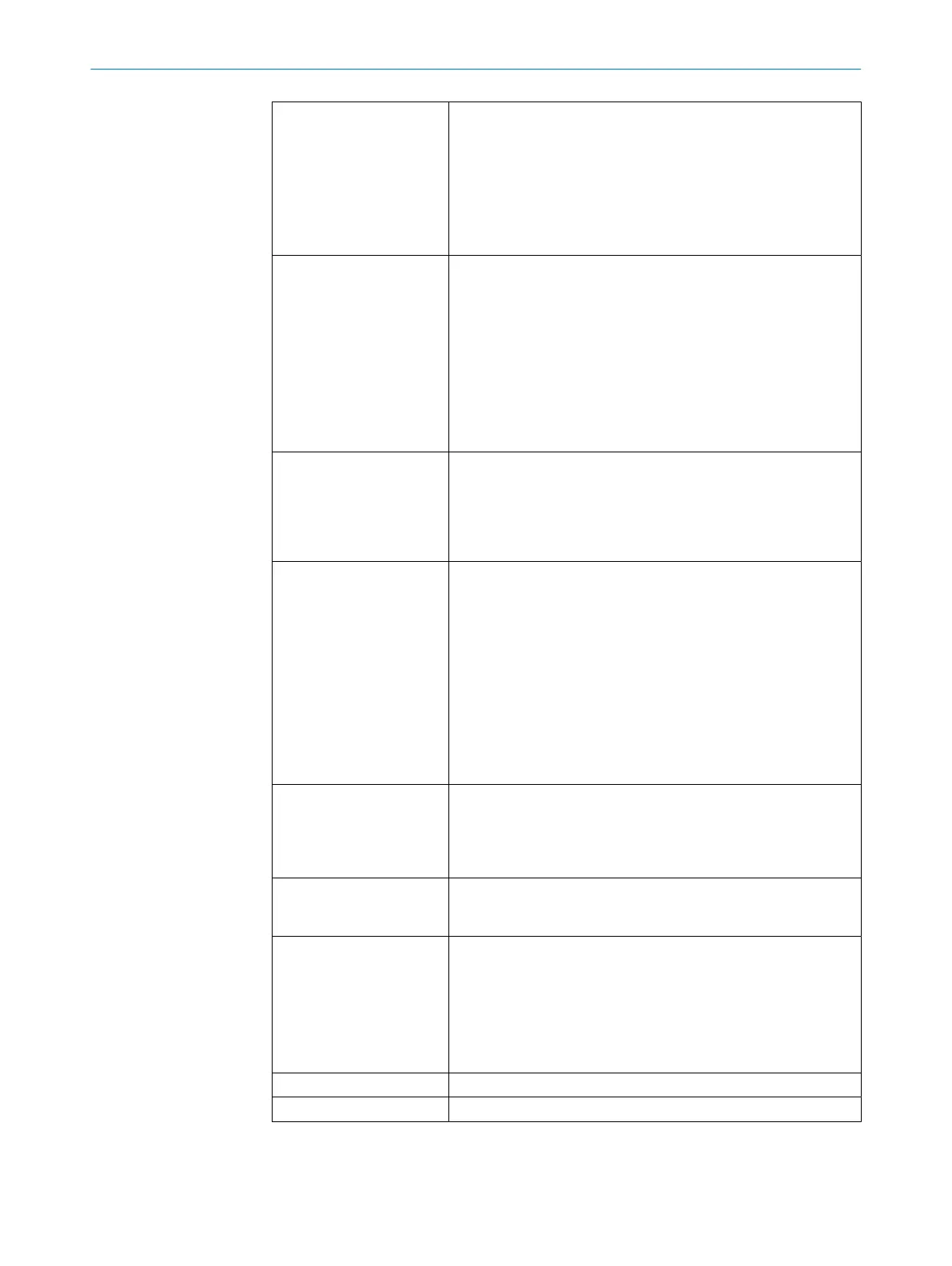

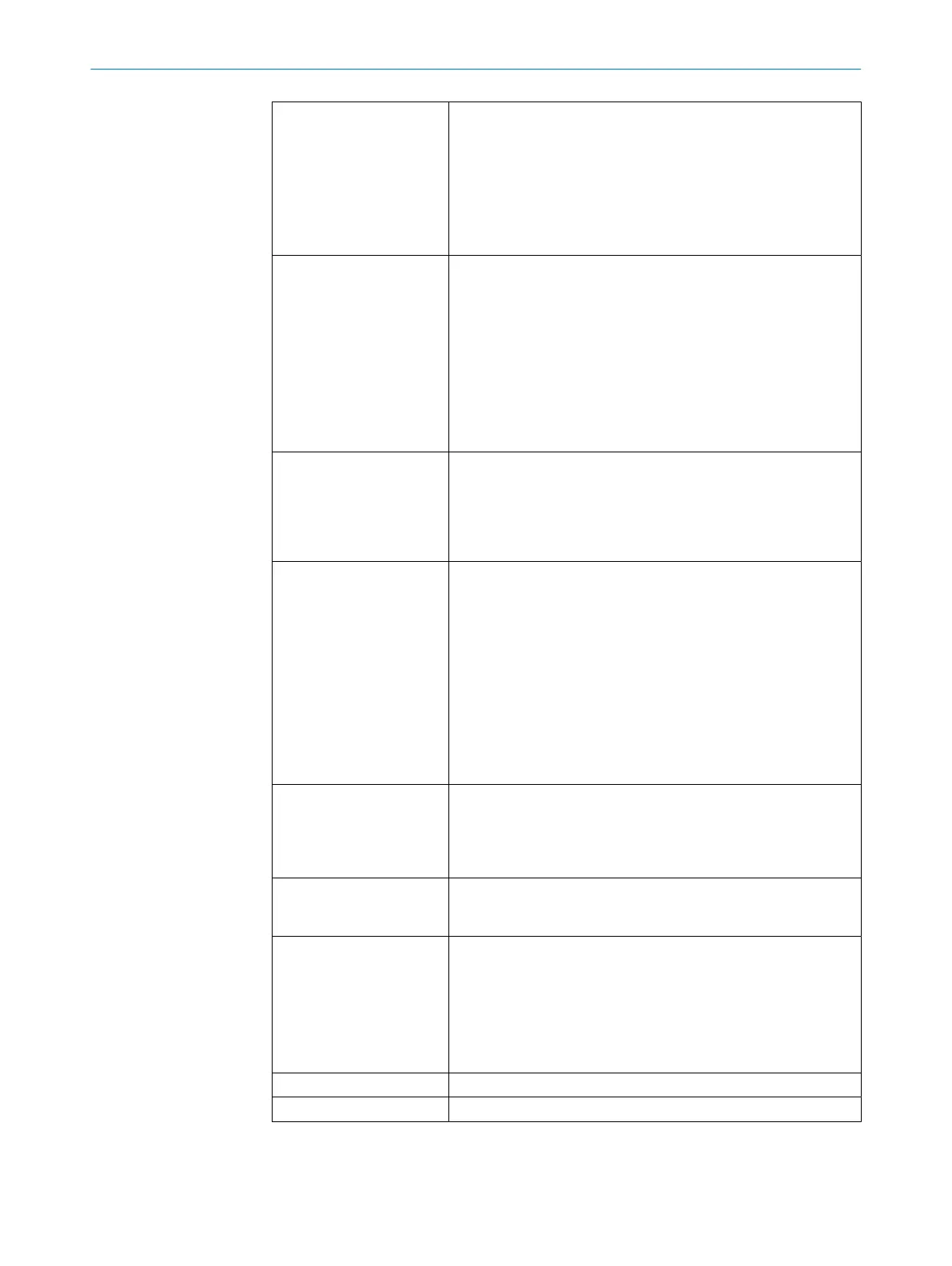

External device monitoring The external device monitoring (EDM) monitors the status of down‐

s

tream contactors.

In order to use external device monitoring, positively guided con‐

tactors must be used to switch off the machine. If the auxiliary

contacts of the positively guided contactors are connected to the

external device monitoring, the external device monitoring checks

whether the contactors switch correctly when the OSSDs are

switched off.

Field set A field set consists of one or more fields. The fields in a field set

ar

e monitored simultaneously.

A field set can contain various types of field.

A typical application is the use of a protective field with one or

more warning fields: if a vehicle approaches a person, a warning

field triggers an optical or acoustic signal. If the person does

not react to this and the vehicle continues to approach, the

safety laser scanner detects an object in the protective field and

switches the associated safety outputs to the OFF state. The vehi‐

cle stops before it reaches the person.

Master The master device actively builds data connections in a network.

A de

vice in a network which is addressed by a master device has

the role of slave.

In some modern networks, many or all devices can switch

between roles or have both roles at one time.

Monitoring case A monitoring case signals the machine status to the safety laser

sc

anner. The safety laser scanner activates the field set, which

is assigned to the monitoring case and therefore a particular

machine status.

If a machine, e.g., has various operational statuses, a monitoring

case can be assigned to each operational status. The safety laser

scanner receives a defined signal for the current operational sta‐

tus via the control inputs or the network. If there is a change of

signal, the safety laser scanner switches from one monitoring case

to the monitoring case that is assigned to the new signal (as well

as the new operational status). Generally, one field set is assigned

to each monitoring case.

OFF state The OFF state is the status of the outputs of the protective device,

wher

e the controlled machine is triggered to quit its dangerous

state and the start-up of the machine is prevented (e.g., the volt‐

age at the OSSDs is LOW, so that the machine is switched off and

remains still).

ON state The ON state is the status of the outputs of the ESPE, where the

controlled machine is permitted to operate (e.g., the voltage at the

OSSDs is HIGH so that the machine can run).

OSSD Output signal switching device: signal output for the protective

de

vice, which is used for stopping the dangerous movement.

An OSSD is a safety switching output. The functionality of each

OSSD is tested periodically. OSSDs are always connected in pairs

and must undergo dual-channel analysis for safety reasons. An

OSSD pair is formed from 2 OSSDs that are connected and ana‐

lyzed together.

PFHD Probability of dangerous failure per hour

PL Performance level (ISO 13849)

15 GLOSSARY

154

O P E R A T I N G I N S T R U C T I O N S | microScan3 Core I/O 8025870/2020-09-04 | SICK

Subject to change without notice

Loading...

Loading...